Manganese ore crushing and processing solution with a daily processing capacity of 4,000 tonsLiming Group customized an efficient crushing production line for a manganese mining area, equipped with PE series jaw crusher, HST series s

Manganese ore crushing and processing solution with a daily processing capacity of 4,000 tons

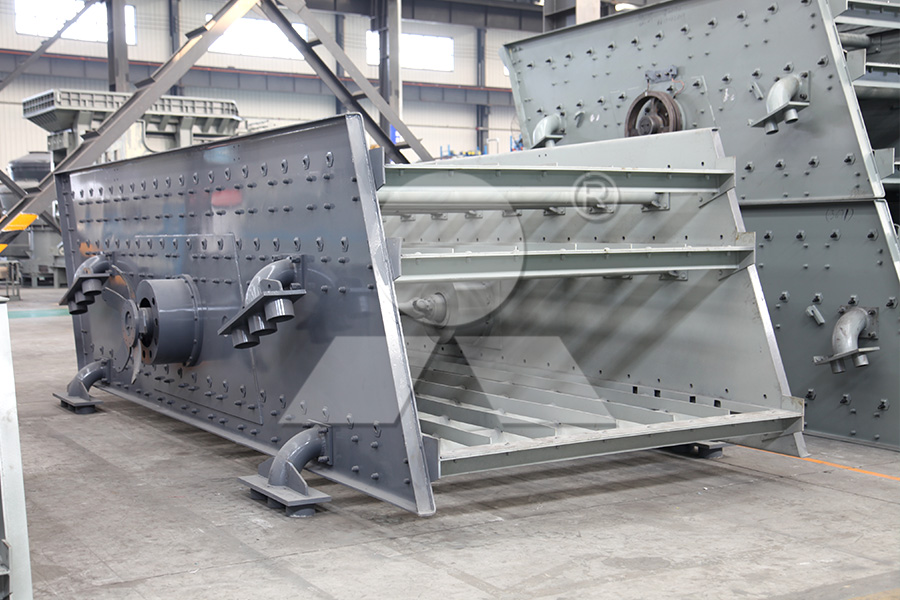

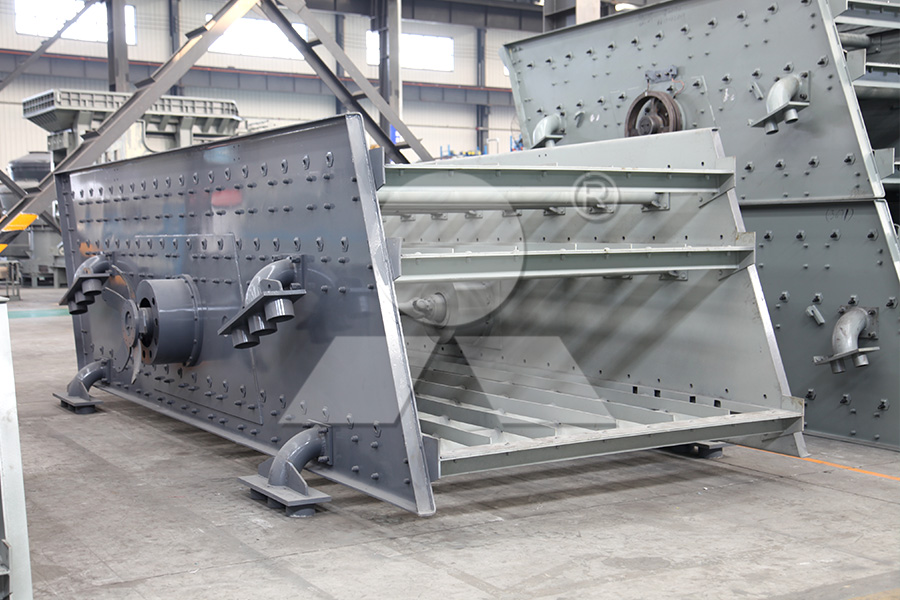

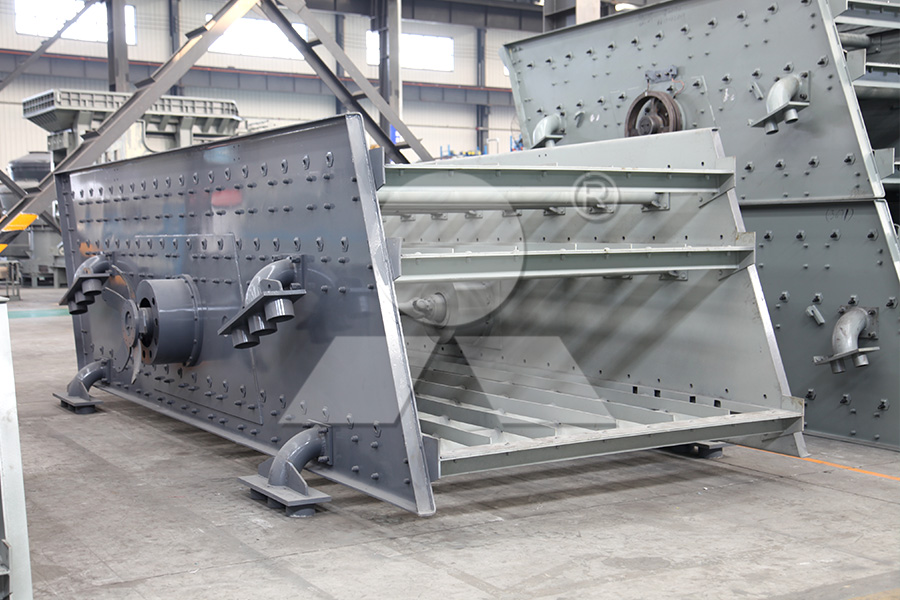

Liming Group customized an efficient crushing production line for a manganese mining area, equipped with PE series jaw crusher, HST series single-cylinder hydraulic cone crusher and HPT series multi-cylinder hydraulic cone crusher, to achieve a daily processing capacity of 4,000 tons of manganese ore, stable finished product quality, improved production capacity and benefits, and won praise from customers.

Equipment configuration: PE series jaw crusher + HST series single-cylinder hydraulic cone crusher + HPT series multi-cylinder hydraulic cone crusher

Manganese ore is an indispensable raw material in modern industry, and it is widely used in steel, chemical industry, batteries and other fields. However, the crushing and processing of manganese ore is not easy. How to process a large amount of manganese ore efficiently and at low cost is an important challenge faced by mining companies. The following is a case study of manganese ore crushing with a daily processing capacity of up to 4,000 tons, showing how efficient equipment configuration can help companies achieve production goals.

1. Project background

The project is located in a large manganese mining area in China, and customers have strict requirements on output and finished product quality. After many investigations and tests, Liming Group tailored a set of efficient and stable crushing production lines for it to ensure that it can achieve the best crushing effect while meeting the production demand.

2. Equipment configuration and process flow

1. Primary crushing: PE series jaw crusher

As primary crushing equipment, the PE series jaw crusher performs well in processing large pieces of manganese ore. Its efficient crushing capacity and stable performance enable the primary crushing link to proceed smoothly, laying a solid foundation for the subsequent fine crushing link.

2. Medium and fine crushing: HST series single-cylinder hydraulic cone crusher

After primary crushing, the manganese ore is transported to the HST series single-cylinder hydraulic cone crusher for medium and fine crushing. The equipment has efficient crushing capacity and precise adjustment function to ensure that each piece of manganese ore can meet the ideal particle size requirements. At the same time, the automatic control system of the HST series cone crusher improves production efficiency and equipment stability.

3. Fine crushing: HPT series multi-cylinder hydraulic cone crusher

As the last process of the entire crushing process, the HPT series multi-cylinder hydraulic cone crusher further processes manganese ore into the fine material required by customers with its excellent fine crushing ability and stable operation status. Its multi-cylinder design not only improves the crushing efficiency, but also significantly reduces the downtime of the equipment, providing a strong guarantee for the efficient operation of the entire production line.

III. Project results

Through the scientific configuration of PE series jaw crusher, HST series single-cylinder hydraulic cone crusher and HPT series multi-cylinder hydraulic cone crusher, the manganese ore crushing production line has achieved the goal of processing 4,000 tons per day, with stable quality and uniform particle size of finished products, meeting the strict requirements of customers. The successful operation of this production line not only improves the production capacity of the enterprise, but also provides valuable reference experience for the same industry.

IV. Customer feedback

The customer highly praised this crushing production line, believing that it not only achieved the expected goals in terms of output and quality, but also performed well in energy consumption and maintenance costs. This set of efficient crushing equipment configuration helps customers occupy a favorable position in market competition and improves the overall benefits of the enterprise.

The success of this manganese ore crushing case not only demonstrates Liming's professional capabilities in equipment configuration and process design, but also reflects its determination and strength to provide customers with efficient solutions. Liming Group will continue to be committed to technological innovation and service optimization, provide high-quality crushing solutions for more mining companies, and jointly promote the development and progress of the industry.

Previous: SMP Crusher

Next: SMP Crusher

Manganese ore crushing and processing solution with a daily processing capacity of 4,000 tonsLiming Group customized an efficient crushing production line for a manganese mining area, equipped with PE series jaw crusher, HST series s

Manganese ore crushing and processing solution with a daily processing capacity of 4,000 tons

Liming Group customized an efficient crushing production line for a manganese mining area, equipped with PE series jaw crusher, HST series single-cylinder hydraulic cone crusher and HPT series multi-cylinder hydraulic cone crusher, to achieve a daily processing capacity of 4,000 tons of manganese ore, stable finished product quality, improved production capacity and benefits, and won praise from customers.

Equipment configuration: PE series jaw crusher + HST series single-cylinder hydraulic cone crusher + HPT series multi-cylinder hydraulic cone crusher

Manganese ore is an indispensable raw material in modern industry, and it is widely used in steel, chemical industry, batteries and other fields. However, the crushing and processing of manganese ore is not easy. How to process a large amount of manganese ore efficiently and at low cost is an important challenge faced by mining companies. The following is a case study of manganese ore crushing with a daily processing capacity of up to 4,000 tons, showing how efficient equipment configuration can help companies achieve production goals.

1. Project background

The project is located in a large manganese mining area in China, and customers have strict requirements on output and finished product quality. After many investigations and tests, Liming Group tailored a set of efficient and stable crushing production lines for it to ensure that it can achieve the best crushing effect while meeting the production demand.

2. Equipment configuration and process flow

1. Primary crushing: PE series jaw crusher

As primary crushing equipment, the PE series jaw crusher performs well in processing large pieces of manganese ore. Its efficient crushing capacity and stable performance enable the primary crushing link to proceed smoothly, laying a solid foundation for the subsequent fine crushing link.

2. Medium and fine crushing: HST series single-cylinder hydraulic cone crusher

After primary crushing, the manganese ore is transported to the HST series single-cylinder hydraulic cone crusher for medium and fine crushing. The equipment has efficient crushing capacity and precise adjustment function to ensure that each piece of manganese ore can meet the ideal particle size requirements. At the same time, the automatic control system of the HST series cone crusher improves production efficiency and equipment stability.

3. Fine crushing: HPT series multi-cylinder hydraulic cone crusher

As the last process of the entire crushing process, the HPT series multi-cylinder hydraulic cone crusher further processes manganese ore into the fine material required by customers with its excellent fine crushing ability and stable operation status. Its multi-cylinder design not only improves the crushing efficiency, but also significantly reduces the downtime of the equipment, providing a strong guarantee for the efficient operation of the entire production line.

III. Project results

Through the scientific configuration of PE series jaw crusher, HST series single-cylinder hydraulic cone crusher and HPT series multi-cylinder hydraulic cone crusher, the manganese ore crushing production line has achieved the goal of processing 4,000 tons per day, with stable quality and uniform particle size of finished products, meeting the strict requirements of customers. The successful operation of this production line not only improves the production capacity of the enterprise, but also provides valuable reference experience for the same industry.

IV. Customer feedback

The customer highly praised this crushing production line, believing that it not only achieved the expected goals in terms of output and quality, but also performed well in energy consumption and maintenance costs. This set of efficient crushing equipment configuration helps customers occupy a favorable position in market competition and improves the overall benefits of the enterprise.

The success of this manganese ore crushing case not only demonstrates Liming's professional capabilities in equipment configuration and process design, but also reflects its determination and strength to provide customers with efficient solutions. Liming Group will continue to be committed to technological innovation and service optimization, provide high-quality crushing solutions for more mining companies, and jointly promote the development and progress of the industry.

Previous: SMP Crusher

Next: SMP Crusher

Granite and basalt cone crusher models introduction

Granite and basalt cone crusher models introduction How much does a large sand making machine cost

How much does a large sand making machine cost What are the advantages of MK mobile crushing and screening station

What are the advantages of MK mobile crushing and screening station New breakthrough in basalt sand making efficient technology leads to new changes in the sand and gravel industry

New breakthrough in basalt sand making efficient technology leads to new changes in the sand and gravel industry Zhejiang Wenzhou Ruian transfers 98 million tons of building stones with a starting price of over 3 billion yuan

Zhejiang Wenzhou Ruian transfers 98 million tons of building stones with a starting price of over 3 billion yuan Granite and basalt cone crusher models introduction

Granite and basalt cone crusher models introduction How much does a large sand making machine cost

How much does a large sand making machine cost What are the advantages of MK mobile crushing and screening station

What are the advantages of MK mobile crushing and screening station New breakthrough in basalt sand making efficient technology leads to new changes in the sand and gravel industry

New breakthrough in basalt sand making efficient technology leads to new changes in the sand and gravel industry Zhejiang Wenzhou Ruian transfers 98 million tons of building stones with a starting price of over 3 billion yuan

Zhejiang Wenzhou Ruian transfers 98 million tons of building stones with a starting price of over 3 billion yuan