In modern construction engineering, the importance of stone as a basic material is self-evident. In order to meet the needs of different projects for stones, it is very important to choose the right stone crushing equipment. For different stone raw mat

In modern construction engineering, the importance of stone as a basic material is self-evident. In order to meet the needs of different projects for stones, it is very important to choose the right stone crushing equipment. For different stone raw materials, the choice of crushing equipment also has a certain attention. So, how to choose the right stone crushing equipment?

Stone crushing equipment

What are the commonly used stone crushing equipment?

1. Jaw crusher

Jaw crusher is often used in the primary crushing of stone. It crushes large pieces of stone by crushing the principle of crushing. The design of deep crushing cavity and no dead zone not only improves the throughput, but also enhances the production efficiency. The equipment adopts oversized bearings and forged spindles, which have stronger bearing capacity, and the flywheel design can effectively reduce vibration and ensure the smooth operation of the equipment.

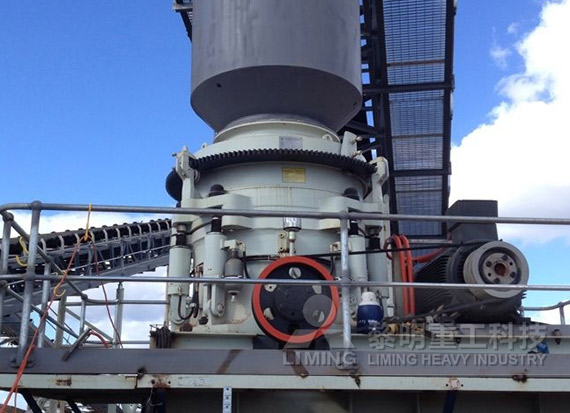

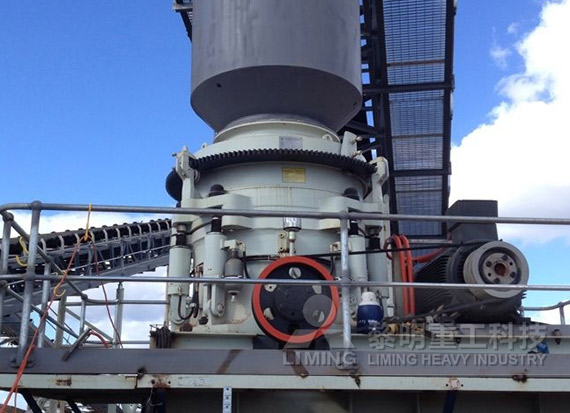

2. Impact crusher and cone crusher

These devices are usually used for secondary crushing. The impact crusher is crushed by repeated impacts between the plate hammer and the impact plate. The finished stone has good grain shape, cube shape and high comprehensive benefit. The cone crusher uses the crushing wall and the rolling mortar wall to crush the material, which is suitable for all kinds of soft and hard ore, and has the characteristics of large crushing ratio, high efficiency and low energy consumption.

3. Impact crusher

The impact crusher is also called a sand making machine. In addition to the fine crushing function, it also has a certain shaping effect. The broken product has a low content of needle-like flakes and is mostly cubic, so it is especially suitable for construction and engineering fields with high requirements on aggregate grain type.

How to choose suitable crushing equipment?

Basis for equipment selection:

The combination of extrusion crushing equipment and impact crushing equipment: Although the jaw crusher and cone crusher are highly efficient extrusion equipment, but to obtain high-quality sand and gravel aggregate, it is usually necessary to use the impact crusher to finish the finished stone. The combination of the two can achieve better production results.

Selection of equipment type:

Fixed and mobile crushing equipment: If the work site is fixed, it is more cost-effective to choose fixed equipment. Mobile crushing equipment is more efficient if dispersed materials need to be handled.

Matching budget to requirements:

Investment budget and equipment performance: The price of stone crushing equipment varies greatly. Generally, the price of new equipment is higher than that of old equipment, and the price of equipment with large output is relatively more expensive. According to the actual needs and investment budget, reasonable selection of equipment, in order to ensure the efficient operation of the project.

Factors affecting the price of stone crushing equipment.

Model and output: The model and output of the equipment are the main factors affecting the price. Different types of equipment have different production capacity and performance, and the price is naturally different.

Brand and quality: brand, quality and after-sales service are also important factors affecting the price of equipment. When choosing, in addition to paying attention to the price, we should also consider the performance, quality and after-sales service of the equipment.

Whether in construction, roads or bridges, stone crushing equipment plays an indispensable role. Choosing the right equipment can not only improve production efficiency, but also ensure the quality of finished stones. Shibang Group provides a variety of high-efficiency stone crushing equipment to meet different engineering needs and escort your project.

Previous: SMP Crusher

Next: SMP Crusher

In modern construction engineering, the importance of stone as a basic material is self-evident. In order to meet the needs of different projects for stones, it is very important to choose the right stone crushing equipment. For different stone raw mat

In modern construction engineering, the importance of stone as a basic material is self-evident. In order to meet the needs of different projects for stones, it is very important to choose the right stone crushing equipment. For different stone raw materials, the choice of crushing equipment also has a certain attention. So, how to choose the right stone crushing equipment?

Stone crushing equipment

What are the commonly used stone crushing equipment?

1. Jaw crusher

Jaw crusher is often used in the primary crushing of stone. It crushes large pieces of stone by crushing the principle of crushing. The design of deep crushing cavity and no dead zone not only improves the throughput, but also enhances the production efficiency. The equipment adopts oversized bearings and forged spindles, which have stronger bearing capacity, and the flywheel design can effectively reduce vibration and ensure the smooth operation of the equipment.

2. Impact crusher and cone crusher

These devices are usually used for secondary crushing. The impact crusher is crushed by repeated impacts between the plate hammer and the impact plate. The finished stone has good grain shape, cube shape and high comprehensive benefit. The cone crusher uses the crushing wall and the rolling mortar wall to crush the material, which is suitable for all kinds of soft and hard ore, and has the characteristics of large crushing ratio, high efficiency and low energy consumption.

3. Impact crusher

The impact crusher is also called a sand making machine. In addition to the fine crushing function, it also has a certain shaping effect. The broken product has a low content of needle-like flakes and is mostly cubic, so it is especially suitable for construction and engineering fields with high requirements on aggregate grain type.

How to choose suitable crushing equipment?

Basis for equipment selection:

The combination of extrusion crushing equipment and impact crushing equipment: Although the jaw crusher and cone crusher are highly efficient extrusion equipment, but to obtain high-quality sand and gravel aggregate, it is usually necessary to use the impact crusher to finish the finished stone. The combination of the two can achieve better production results.

Selection of equipment type:

Fixed and mobile crushing equipment: If the work site is fixed, it is more cost-effective to choose fixed equipment. Mobile crushing equipment is more efficient if dispersed materials need to be handled.

Matching budget to requirements:

Investment budget and equipment performance: The price of stone crushing equipment varies greatly. Generally, the price of new equipment is higher than that of old equipment, and the price of equipment with large output is relatively more expensive. According to the actual needs and investment budget, reasonable selection of equipment, in order to ensure the efficient operation of the project.

Factors affecting the price of stone crushing equipment.

Model and output: The model and output of the equipment are the main factors affecting the price. Different types of equipment have different production capacity and performance, and the price is naturally different.

Brand and quality: brand, quality and after-sales service are also important factors affecting the price of equipment. When choosing, in addition to paying attention to the price, we should also consider the performance, quality and after-sales service of the equipment.

Whether in construction, roads or bridges, stone crushing equipment plays an indispensable role. Choosing the right equipment can not only improve production efficiency, but also ensure the quality of finished stones. Shibang Group provides a variety of high-efficiency stone crushing equipment to meet different engineering needs and escort your project.

Previous: SMP Crusher

Next: SMP Crusher

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation 69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment

69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation 69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment

69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment