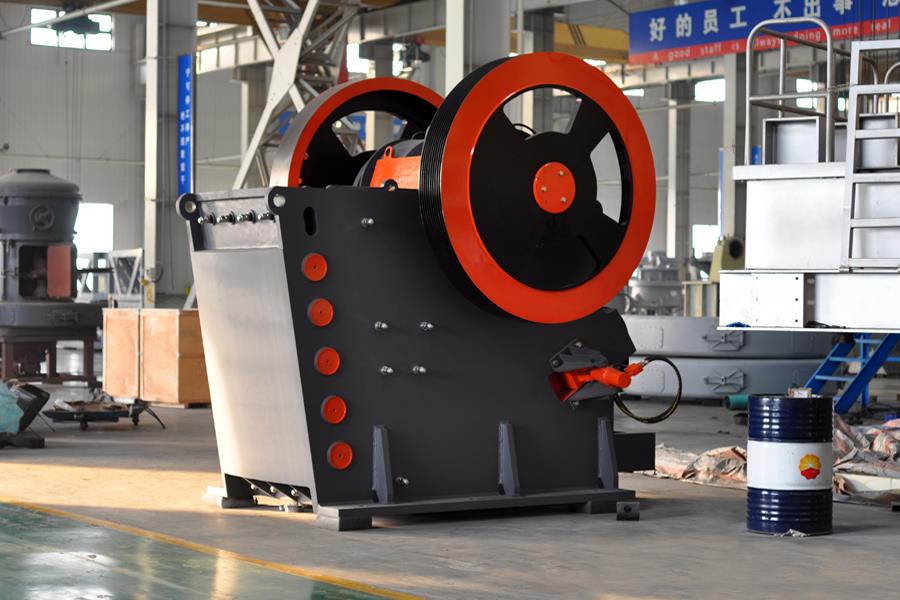

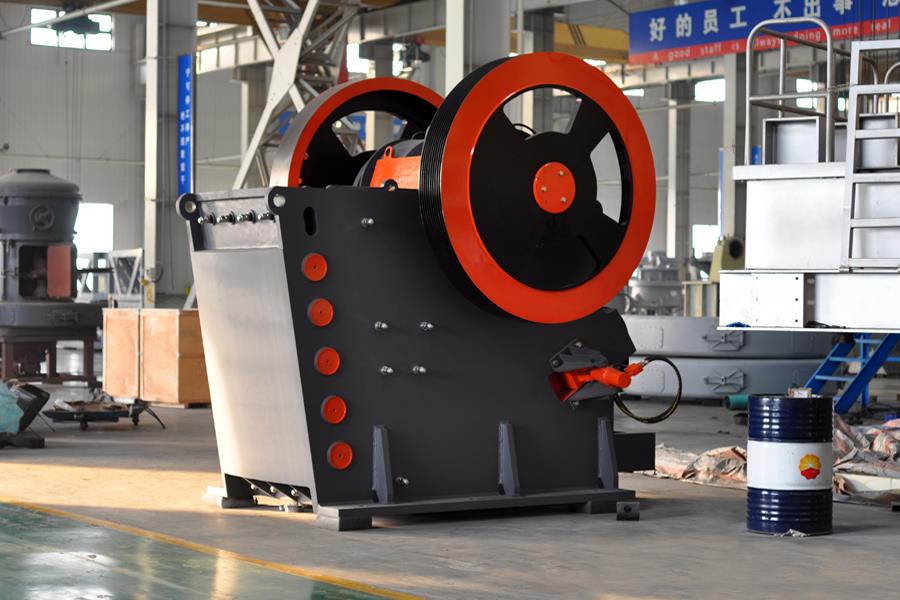

During the use of the jaw crusher, a large amount of dust will be produced, which will cause serious pollution to the environment. How to solve the problem of jaw crusher dust has become an urgent problem to be solved.Understand the

During the use of the jaw crusher, a large amount of dust will be produced, which will cause serious pollution to the environment. How to solve the problem of jaw crusher dust has become an urgent problem to be solved.

Understand the stone production line dust problem click consultation

Hazards of 1. Jaw Crusher Dust Problem

When the jaw crusher is working, the material is squeezed and crushed mainly through the interaction between the movable jaw and the fixed jaw. However, a large amount of dust is generated during this 1 process. These dust will not only have a serious impact on the working environment and reduce air quality, but also may be scattered in the wind, causing significant pollution to the surrounding environment and the wider ecosystem.

Solution to the Dust Problem of 2. Jaw Crusher

In order to solve the problem of jaw crusher dust, we need to start from many aspects and take various measures to achieve effective treatment effect.

1. Adopt efficient dust removal equipment

The dust problem generated by the jaw crusher during the working process can be effectively solved by using high-efficiency dust removal equipment. There are many types of dust removal equipment on the market, such as cyclone dust collectors, electrostatic precipitators, etc., which all exhibit good dust removal effects. Through reasonable selection and configuration of these dust removal equipment, the dust produced by the jaw crusher can be significantly reduced, thereby reducing environmental pollution.

2. Optimize equipment structure

In addition to using high-efficiency dust removal equipment, we can also solve the dust problem by optimizing the equipment structure of the jaw crusher. Specific measures include setting a sealing device at the inlet and outlet of the jaw crusher to effectively prevent the overflow of dust. At the same time, in the actual use of equipment, we should also take a series of measures to minimize the generation of dust, such as water spray, wet crushing and other methods, so as to further reduce environmental pollution.

3. Establish a sound management system

In addition to taking the above measures, we also need to establish a sound management system to strictly manage the use of jaw crushers. For example, the use of jaw crushers can be regularly inspected and maintained to clean up the dust inside the equipment in time to prevent dust accumulation

Previous: SMP Crusher

Next: SMP Crusher

During the use of the jaw crusher, a large amount of dust will be produced, which will cause serious pollution to the environment. How to solve the problem of jaw crusher dust has become an urgent problem to be solved.Understand the

During the use of the jaw crusher, a large amount of dust will be produced, which will cause serious pollution to the environment. How to solve the problem of jaw crusher dust has become an urgent problem to be solved.

Understand the stone production line dust problem click consultation

Hazards of 1. Jaw Crusher Dust Problem

When the jaw crusher is working, the material is squeezed and crushed mainly through the interaction between the movable jaw and the fixed jaw. However, a large amount of dust is generated during this 1 process. These dust will not only have a serious impact on the working environment and reduce air quality, but also may be scattered in the wind, causing significant pollution to the surrounding environment and the wider ecosystem.

Solution to the Dust Problem of 2. Jaw Crusher

In order to solve the problem of jaw crusher dust, we need to start from many aspects and take various measures to achieve effective treatment effect.

1. Adopt efficient dust removal equipment

The dust problem generated by the jaw crusher during the working process can be effectively solved by using high-efficiency dust removal equipment. There are many types of dust removal equipment on the market, such as cyclone dust collectors, electrostatic precipitators, etc., which all exhibit good dust removal effects. Through reasonable selection and configuration of these dust removal equipment, the dust produced by the jaw crusher can be significantly reduced, thereby reducing environmental pollution.

2. Optimize equipment structure

In addition to using high-efficiency dust removal equipment, we can also solve the dust problem by optimizing the equipment structure of the jaw crusher. Specific measures include setting a sealing device at the inlet and outlet of the jaw crusher to effectively prevent the overflow of dust. At the same time, in the actual use of equipment, we should also take a series of measures to minimize the generation of dust, such as water spray, wet crushing and other methods, so as to further reduce environmental pollution.

3. Establish a sound management system

In addition to taking the above measures, we also need to establish a sound management system to strictly manage the use of jaw crushers. For example, the use of jaw crushers can be regularly inspected and maintained to clean up the dust inside the equipment in time to prevent dust accumulation

Previous: SMP Crusher

Next: SMP Crusher

The difference between tailings sand and machine-made sand and the application of tailings sand making equipment

The difference between tailings sand and machine-made sand and the application of tailings sand making equipment How to choose the equipment suitable for basalt sand making

How to choose the equipment suitable for basalt sand making How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme The difference between tailings sand and machine-made sand and the application of tailings sand making equipment

The difference between tailings sand and machine-made sand and the application of tailings sand making equipment How to choose the equipment suitable for basalt sand making

How to choose the equipment suitable for basalt sand making How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme