The configuration of the tuff sand and gravel production line for construction accurately connects the particle size of raw materials with the particle size of customer requirements, while comprehensively considering the actual conditions such as the p

The configuration of the tuff sand and gravel production line for construction accurately connects the particle size of raw materials with the particle size of customer requirements, while comprehensively considering the actual conditions such as the production site environment and production capacity scale. From raw material crushing and screening to finished sand production, each step is tailored to ensure high efficiency, environmental protection and economy. This flexible allocation strategy not only optimizes the use of resources, but also improves product quality and production efficiency to meet the diverse building needs. Here mainly to Shibang Group Zhejiang Haiyan annual output of 7 million tons of tuff sand and gravel production line configuration as an example, specific introduction:

Sand aggregate production line construction plan click consultation

Project Summary:

Project scale: annual output of 7 million tons

Processing materials: tuff, fine porphyry

Finished product specification: 0-5mm fine manufactured sand; 5-10mm, 10-20mm fine crushed stone; 7-13mm, 13-25mm crushed stone

Treatment process: wet process

Finished product use: highway, highway construction

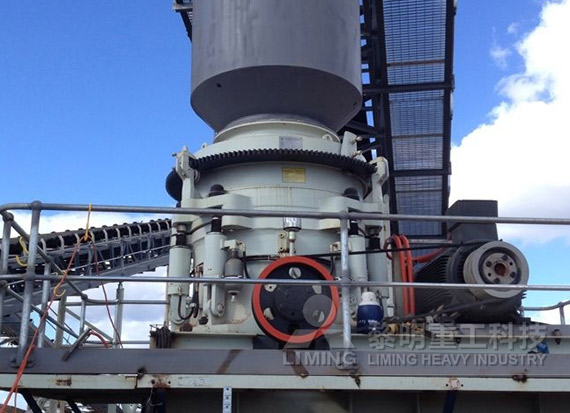

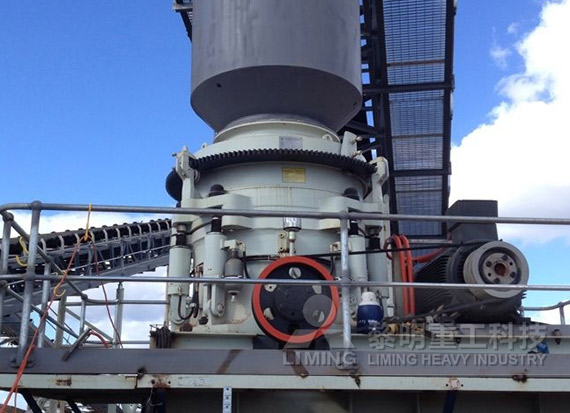

Use equipment: Shibang F5X feeder HPT multi-cylinder hydraulic cone breaker VSI6X sand making machine S5X vibrating screen

The project is equipped with double sand and gravel lines, using "three-stage crushing, two-stage washing and screening, and one-stage shaping sand" to accurately produce multi-specification high quality sand and gravel aggregates to meet the high-standard needs of buildings, bridges, railways and so on. Fully enclosed plant design, strict control of dust and noise, the practice of green production, wet process to ensure low powder and low mud aggregate, improve cleanliness and quality.

Previous: SMP Crusher

Next: SMP Crusher

The configuration of the tuff sand and gravel production line for construction accurately connects the particle size of raw materials with the particle size of customer requirements, while comprehensively considering the actual conditions such as the p

The configuration of the tuff sand and gravel production line for construction accurately connects the particle size of raw materials with the particle size of customer requirements, while comprehensively considering the actual conditions such as the production site environment and production capacity scale. From raw material crushing and screening to finished sand production, each step is tailored to ensure high efficiency, environmental protection and economy. This flexible allocation strategy not only optimizes the use of resources, but also improves product quality and production efficiency to meet the diverse building needs. Here mainly to Shibang Group Zhejiang Haiyan annual output of 7 million tons of tuff sand and gravel production line configuration as an example, specific introduction:

Sand aggregate production line construction plan click consultation

Project Summary:

Project scale: annual output of 7 million tons

Processing materials: tuff, fine porphyry

Finished product specification: 0-5mm fine manufactured sand; 5-10mm, 10-20mm fine crushed stone; 7-13mm, 13-25mm crushed stone

Treatment process: wet process

Finished product use: highway, highway construction

Use equipment: Shibang F5X feeder HPT multi-cylinder hydraulic cone breaker VSI6X sand making machine S5X vibrating screen

The project is equipped with double sand and gravel lines, using "three-stage crushing, two-stage washing and screening, and one-stage shaping sand" to accurately produce multi-specification high quality sand and gravel aggregates to meet the high-standard needs of buildings, bridges, railways and so on. Fully enclosed plant design, strict control of dust and noise, the practice of green production, wet process to ensure low powder and low mud aggregate, improve cleanliness and quality.

Previous: SMP Crusher

Next: SMP Crusher

What are the basalt stone processing equipment

What are the basalt stone processing equipment How to choose stone crushing equipment

How to choose stone crushing equipment Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs What are the basalt stone processing equipment

What are the basalt stone processing equipment How to choose stone crushing equipment

How to choose stone crushing equipment Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs