If large basalt is to be processed into usable stones or machine-made sand with smaller particle size, basalt stone processing equipment is required: jaw crusher, cone crusher, impact crusher (stone shaping), and mobile crusher is required for complex

If large basalt is to be processed into usable stones or machine-made sand with smaller particle size, basalt stone processing equipment is required: jaw crusher, cone crusher, impact crusher (stone shaping), and mobile crusher is required for complex terrain.

Learn about basalt crushing equipment Click to consult

1. Coarse crushing equipment-jaw crusher

Jaw crusher is a powerful primary crushing weapon, commonly known as coarse stone crusher. It adopts the principle of extrusion crushing, specializing in large pieces of stone, with excellent crushing force, stability and wear resistance. As the preliminary stage of material processing, it can effectively reduce the size of stone and lay the foundation for subsequent refinement and crushing. In the process, it is an ideal choice to improve the overall crushing efficiency and quality to ensure that the output of stone powder is less, the impurities are thoroughly removed, and the particle size of the finished stone is uniform.

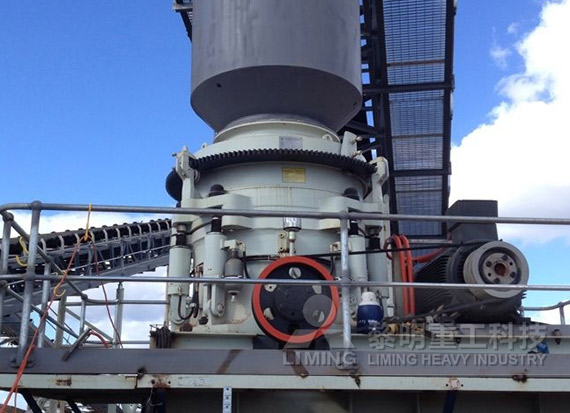

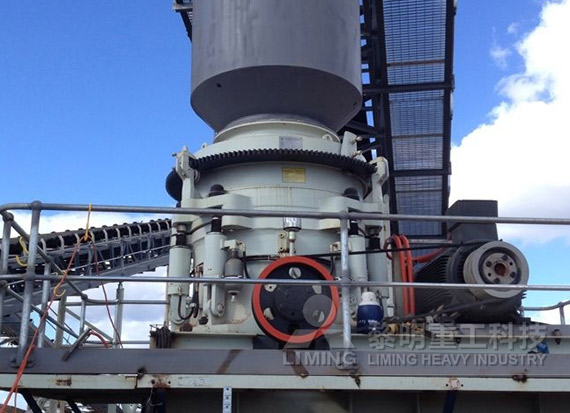

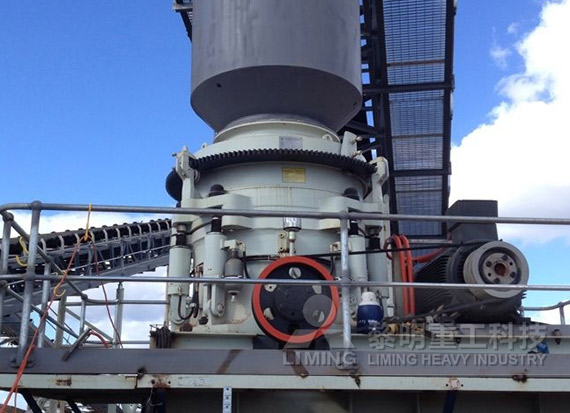

2. Medium and fine crushing equipment-cone crushing

The cone is broken, and the stone factory is finely crushed to optimize, following the jaw breaking process. Good at breaking hard stone, efficient production capacity, low maintenance cost in the later period, excellent wear resistance of the machine. As a fine crushing equipment, it can further improve the quality of stone and ensure fine particle size, which is an ideal choice for efficient crushing of hard stone.

3. Sand making and stone shaping-impact crusher

The impact crusher is used for three-stage stone crushing to crush the finely crushed stone into machine-made sand with finer particle size, with a specification of 1-5mm; Compared with sand making equipment with the same power, the output of the equipment has increased by about 30%, which has the advantages of stone shaping treatment. The finished products are mostly cubic, with good grain shape and grade coordination, and are suitable for artificial sand aggregate construction operations.

Previous: SMP Crusher

Next: SMP Crusher

If large basalt is to be processed into usable stones or machine-made sand with smaller particle size, basalt stone processing equipment is required: jaw crusher, cone crusher, impact crusher (stone shaping), and mobile crusher is required for complex

If large basalt is to be processed into usable stones or machine-made sand with smaller particle size, basalt stone processing equipment is required: jaw crusher, cone crusher, impact crusher (stone shaping), and mobile crusher is required for complex terrain.

Learn about basalt crushing equipment Click to consult

1. Coarse crushing equipment-jaw crusher

Jaw crusher is a powerful primary crushing weapon, commonly known as coarse stone crusher. It adopts the principle of extrusion crushing, specializing in large pieces of stone, with excellent crushing force, stability and wear resistance. As the preliminary stage of material processing, it can effectively reduce the size of stone and lay the foundation for subsequent refinement and crushing. In the process, it is an ideal choice to improve the overall crushing efficiency and quality to ensure that the output of stone powder is less, the impurities are thoroughly removed, and the particle size of the finished stone is uniform.

2. Medium and fine crushing equipment-cone crushing

The cone is broken, and the stone factory is finely crushed to optimize, following the jaw breaking process. Good at breaking hard stone, efficient production capacity, low maintenance cost in the later period, excellent wear resistance of the machine. As a fine crushing equipment, it can further improve the quality of stone and ensure fine particle size, which is an ideal choice for efficient crushing of hard stone.

3. Sand making and stone shaping-impact crusher

The impact crusher is used for three-stage stone crushing to crush the finely crushed stone into machine-made sand with finer particle size, with a specification of 1-5mm; Compared with sand making equipment with the same power, the output of the equipment has increased by about 30%, which has the advantages of stone shaping treatment. The finished products are mostly cubic, with good grain shape and grade coordination, and are suitable for artificial sand aggregate construction operations.

Previous: SMP Crusher

Next: SMP Crusher

How to choose stone crushing equipment

How to choose stone crushing equipment Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation How to choose stone crushing equipment

How to choose stone crushing equipment Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation