Calcite, a common calcium carbonate mineral, has a wide range of applications in industry. It is not only a key material in the fields of chemical industry, cement, metallurgy, plastics and papermaking, but also widely used in various production becaus

Calcite, a common calcium carbonate mineral, has a wide range of applications in industry. It is not only a key material in the fields of chemical industry, cement, metallurgy, plastics and papermaking, but also widely used in various production because of its unique physical properties. So, what equipment is needed for the processing of calcite? What is the price of the entire production equipment?

calcite crushing equipment price

1. calcite production equipment?

The selection of calcite processing equipment needs to be reasonably configured according to its physical properties and actual needs. Common calcite production equipment mainly includes the following:

1. Jaw crusher

It is suitable for coarse crushing of calcite. It has the characteristics of deep crushing cavity, no dead zone, and high efficiency. It can handle larger particles of calcite, ensure uniform discharge particle size, and reduce the difficulty of subsequent processing.

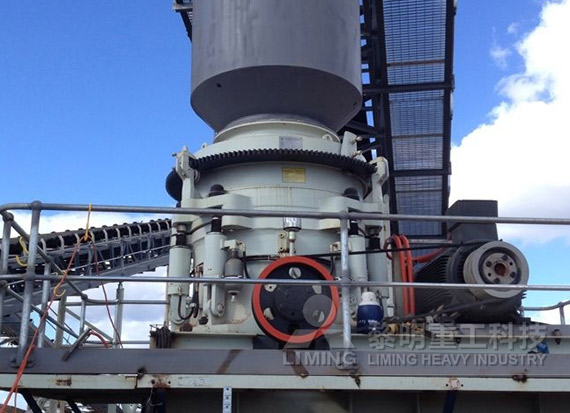

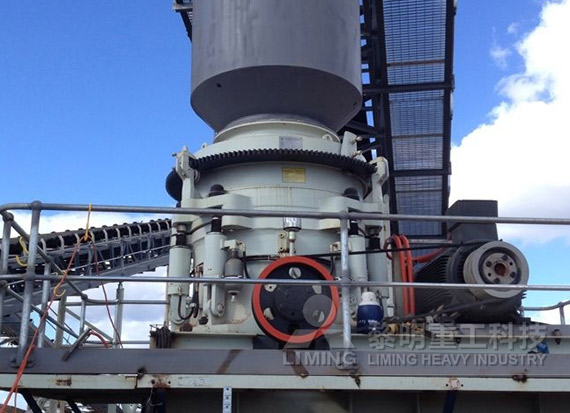

2. Impact crusher

Used for calcite crushing processing. The high-speed rotating rotor is used to drive the plate hammer to crush the calcite for many times. The finished product has good particle size and is suitable for producing products with higher requirements for particle shape.

3. Sand making machine

The ideal choice for calcite sand, the material can be further finely crushed and shaped, the discharge particle size is small and uniform, suitable for the production of high quality sand.

4. Raymond Mill

The key equipment of calcite grinding powder can grind calcite powder to a fineness of 0.173-0.044mm, which is widely used in industries with high requirements on powder fineness.

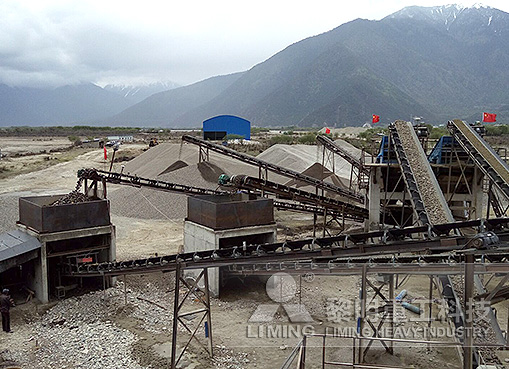

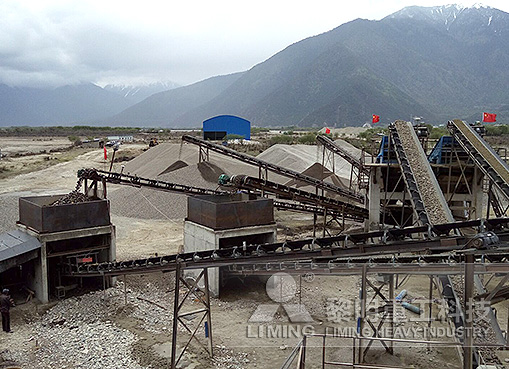

2. calcite processing process and case analysis

The calcite processing is generally divided into coarse crushing, medium and fine crushing, screening and grinding process. According to the specific raw material size, production requirements and finished product specifications, different production lines can be configured. For example, a Guangxi customer's calcite production line uses jaw crushers, impact crushers, vibrating screens and other equipment, which can achieve a production capacity of 200 tons per hour and a finished product specification of 5-30mm.

3. calcite production equipment how much money a set?

The price of calcite complete equipment is affected by many factors, including equipment type, configuration, production demand, manufacturer selection, etc. Generally speaking, the price of the entire production line equipment ranges from hundreds of thousands to millions.

Equipment type: Different types of equipment have different prices. Fine processing equipment such as sand making machines and Raymond mills are usually more expensive.

Configuration scheme: According to the complexity of the production line and the combination of equipment, the price will vary greatly.

Manufacturer selection: The equipment material, process and after-sales service of different manufacturers will also affect the price.

If you need to know the specific quotation, it is recommended to contact the manufacturer directly and consult in detail according to your actual needs. Choosing equipment that suits your own production needs can not only improve production efficiency, but also effectively reduce production costs.

Previous: SMP Crusher

Next: SMP Crusher

Calcite, a common calcium carbonate mineral, has a wide range of applications in industry. It is not only a key material in the fields of chemical industry, cement, metallurgy, plastics and papermaking, but also widely used in various production becaus

Calcite, a common calcium carbonate mineral, has a wide range of applications in industry. It is not only a key material in the fields of chemical industry, cement, metallurgy, plastics and papermaking, but also widely used in various production because of its unique physical properties. So, what equipment is needed for the processing of calcite? What is the price of the entire production equipment?

calcite crushing equipment price

1. calcite production equipment?

The selection of calcite processing equipment needs to be reasonably configured according to its physical properties and actual needs. Common calcite production equipment mainly includes the following:

1. Jaw crusher

It is suitable for coarse crushing of calcite. It has the characteristics of deep crushing cavity, no dead zone, and high efficiency. It can handle larger particles of calcite, ensure uniform discharge particle size, and reduce the difficulty of subsequent processing.

2. Impact crusher

Used for calcite crushing processing. The high-speed rotating rotor is used to drive the plate hammer to crush the calcite for many times. The finished product has good particle size and is suitable for producing products with higher requirements for particle shape.

3. Sand making machine

The ideal choice for calcite sand, the material can be further finely crushed and shaped, the discharge particle size is small and uniform, suitable for the production of high quality sand.

4. Raymond Mill

The key equipment of calcite grinding powder can grind calcite powder to a fineness of 0.173-0.044mm, which is widely used in industries with high requirements on powder fineness.

2. calcite processing process and case analysis

The calcite processing is generally divided into coarse crushing, medium and fine crushing, screening and grinding process. According to the specific raw material size, production requirements and finished product specifications, different production lines can be configured. For example, a Guangxi customer's calcite production line uses jaw crushers, impact crushers, vibrating screens and other equipment, which can achieve a production capacity of 200 tons per hour and a finished product specification of 5-30mm.

3. calcite production equipment how much money a set?

The price of calcite complete equipment is affected by many factors, including equipment type, configuration, production demand, manufacturer selection, etc. Generally speaking, the price of the entire production line equipment ranges from hundreds of thousands to millions.

Equipment type: Different types of equipment have different prices. Fine processing equipment such as sand making machines and Raymond mills are usually more expensive.

Configuration scheme: According to the complexity of the production line and the combination of equipment, the price will vary greatly.

Manufacturer selection: The equipment material, process and after-sales service of different manufacturers will also affect the price.

If you need to know the specific quotation, it is recommended to contact the manufacturer directly and consult in detail according to your actual needs. Choosing equipment that suits your own production needs can not only improve production efficiency, but also effectively reduce production costs.

Previous: SMP Crusher

Next: SMP Crusher

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme What are the basalt stone processing equipment

What are the basalt stone processing equipment How to choose stone crushing equipment

How to choose stone crushing equipment Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme What are the basalt stone processing equipment

What are the basalt stone processing equipment How to choose stone crushing equipment

How to choose stone crushing equipment Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal

Tungsten ore dressing equipment and process: to create a key link in the efficient extraction of tungsten metal How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built?