With the continuous development of the construction industry, the demand for construction sand is increasing. In the past, river sand was the main source of construction sand, but with the decrease of natural resources, people began to turn their atten

With the continuous development of the construction industry, the demand for construction sand is increasing. In the past, river sand was the main source of construction sand, but with the decrease of natural resources, people began to turn their attention to mechanism sand and tailings sand. However, what is the difference between mechanism sand and tailings sand? Can tailings sand be used for construction concrete?

Application of tailings equipment

The difference between 1. mechanism sand and tailings sand

1. Formation process

Machine-made sand is usually made of limestone, pebbles, granite and other ores through crushing, screening and other processes. According to different process requirements, the mechanism sand can be processed into sand of different rules and sizes, which is suitable for various construction projects.

Tailings sand is a product produced in the beneficiation process. In the beneficiation process, the useless part of the ore after separation is called tailings. After treatment, the tailings can be made into sand for reuse. The appearance of the finished product is not much different from that of ordinary mechanism sand, but its composition and characteristics may be different.

2. Quality differences

The raw material of mechanism sand is mostly hard rock, so its finished product usually meets the standard of construction sand, especially in the application of concrete, with excellent performance and strong binding force.

Tailings sand may have poor volume stability or high heavy metal content, which limits its application in construction. Nevertheless, with the continuous innovation of tailings comprehensive utilization technology, the quality of tailings sand is gradually improving.

3. Application areas

Machine-made sand is widely used in construction, municipal, transportation and other engineering projects, especially suitable for concrete with strength grade of C60 and below.

Tailings sand can replace part of the mechanism of sand, used in the production of concrete, highway construction, pavement materials. In addition, tailings sand can also be used to develop wall sound insulation materials, glazed tiles, green belt filling and other fields.

2. tailings sand making equipment

Can tailings sand be used as mechanism sand? The answer is yes. But the premise is that tailings sand must go through crushing, sand and other processing processes, in order to prepare a mechanism to meet the requirements of sand. The following are commonly used tailings sand making equipment:

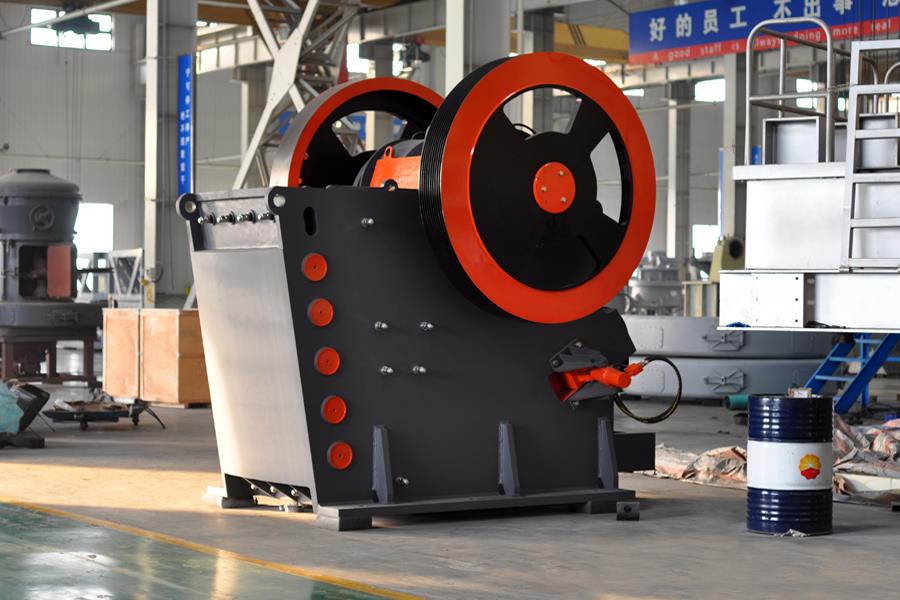

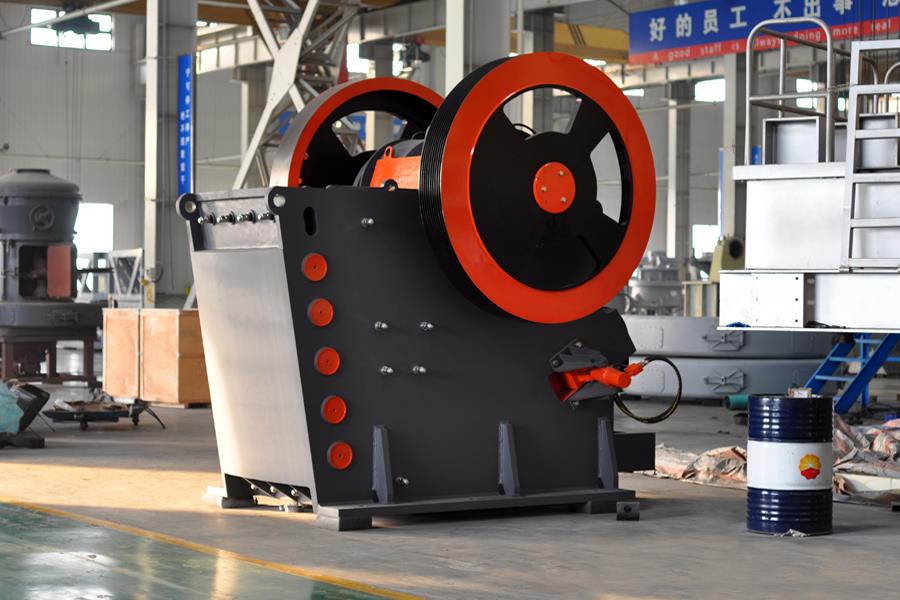

1. Jaw crusher

The jaw crusher is suitable for the preliminary crushing of large tailings. It is characterized by deep crushing cavity and no dead zone, which is suitable for processing raw materials with large particle size. The equipment is durable and easy to operate and maintain. It is the preferred equipment for tailings sand production line.

2. Impact crusher

The impact crusher is suitable for soft rock tailings. The new crushing technology can effectively control the particle size of the material, so that the finished product is better, in line with the standard of construction sand.

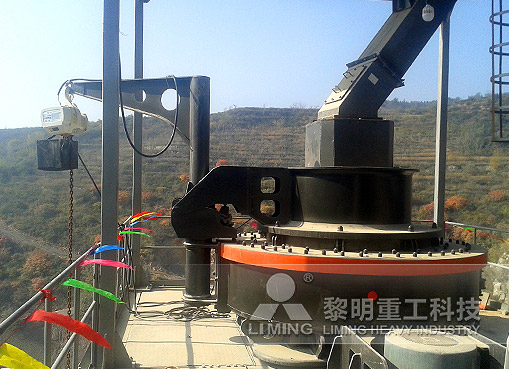

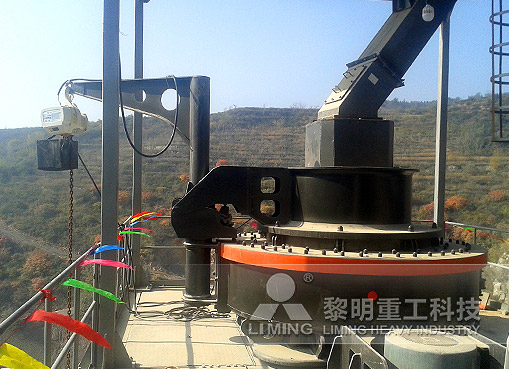

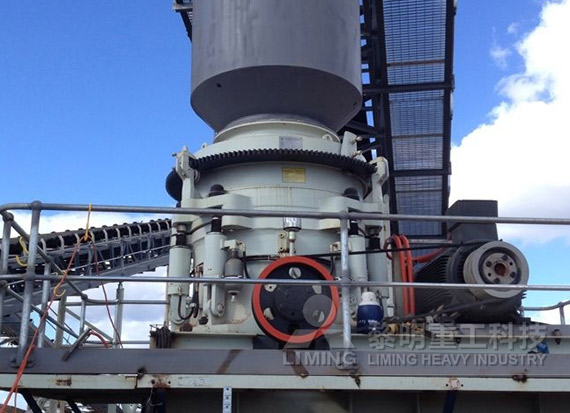

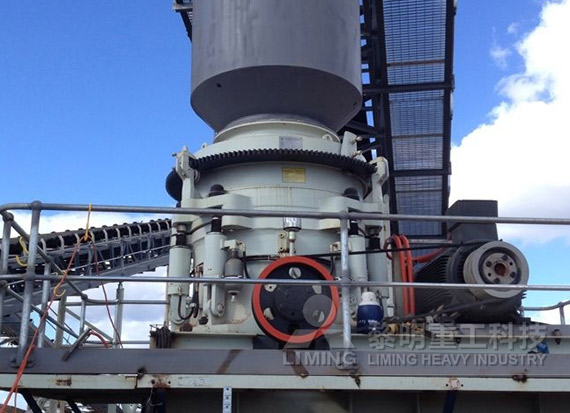

3. Cone crusher

The cone crusher is suitable for crushing hard rock tailings. The equipment design adopts hydraulic adjustment system and laminated crushing cavity type, which is easy to operate and has large crushing force. It can efficiently process hard tailings and produce high-quality sand.

4. Impact type sand making machine

Impact sand making machine is the key equipment in tailings sand production line. Its design can improve the throughput, prevent material blockage, and has a good shaping effect, the final output of the sand grain is good, high quality.

Use of 3. tailings

Tailings sand can be widely used in construction concrete, especially in cement industry, ordinary concrete, cement products and other fields. Because the tailings itself is dry, no additional drying treatment is required, and the price is relatively cheap, so it has economic advantages to a certain extent. However, due to the fine particle size of tailings sand and some chemical residues, it needs to be treated according to the specific situation in the construction application to avoid adverse effects on the construction quality.

Mechanism sand and tailings sand have their own advantages and disadvantages, and play an important role in the construction industry. Through the reasonable selection and use of sand making equipment, the quality of tailings sand can be effectively improved, so that it can be more widely used in construction. Shibang Group is committed to providing high-quality sand making equipment and process solutions to contribute to the development of the construction industry.

Previous: SMP Crusher

Next: SMP Crusher

With the continuous development of the construction industry, the demand for construction sand is increasing. In the past, river sand was the main source of construction sand, but with the decrease of natural resources, people began to turn their atten

With the continuous development of the construction industry, the demand for construction sand is increasing. In the past, river sand was the main source of construction sand, but with the decrease of natural resources, people began to turn their attention to mechanism sand and tailings sand. However, what is the difference between mechanism sand and tailings sand? Can tailings sand be used for construction concrete?

Application of tailings equipment

The difference between 1. mechanism sand and tailings sand

1. Formation process

Machine-made sand is usually made of limestone, pebbles, granite and other ores through crushing, screening and other processes. According to different process requirements, the mechanism sand can be processed into sand of different rules and sizes, which is suitable for various construction projects.

Tailings sand is a product produced in the beneficiation process. In the beneficiation process, the useless part of the ore after separation is called tailings. After treatment, the tailings can be made into sand for reuse. The appearance of the finished product is not much different from that of ordinary mechanism sand, but its composition and characteristics may be different.

2. Quality differences

The raw material of mechanism sand is mostly hard rock, so its finished product usually meets the standard of construction sand, especially in the application of concrete, with excellent performance and strong binding force.

Tailings sand may have poor volume stability or high heavy metal content, which limits its application in construction. Nevertheless, with the continuous innovation of tailings comprehensive utilization technology, the quality of tailings sand is gradually improving.

3. Application areas

Machine-made sand is widely used in construction, municipal, transportation and other engineering projects, especially suitable for concrete with strength grade of C60 and below.

Tailings sand can replace part of the mechanism of sand, used in the production of concrete, highway construction, pavement materials. In addition, tailings sand can also be used to develop wall sound insulation materials, glazed tiles, green belt filling and other fields.

2. tailings sand making equipment

Can tailings sand be used as mechanism sand? The answer is yes. But the premise is that tailings sand must go through crushing, sand and other processing processes, in order to prepare a mechanism to meet the requirements of sand. The following are commonly used tailings sand making equipment:

1. Jaw crusher

The jaw crusher is suitable for the preliminary crushing of large tailings. It is characterized by deep crushing cavity and no dead zone, which is suitable for processing raw materials with large particle size. The equipment is durable and easy to operate and maintain. It is the preferred equipment for tailings sand production line.

2. Impact crusher

The impact crusher is suitable for soft rock tailings. The new crushing technology can effectively control the particle size of the material, so that the finished product is better, in line with the standard of construction sand.

3. Cone crusher

The cone crusher is suitable for crushing hard rock tailings. The equipment design adopts hydraulic adjustment system and laminated crushing cavity type, which is easy to operate and has large crushing force. It can efficiently process hard tailings and produce high-quality sand.

4. Impact type sand making machine

Impact sand making machine is the key equipment in tailings sand production line. Its design can improve the throughput, prevent material blockage, and has a good shaping effect, the final output of the sand grain is good, high quality.

Use of 3. tailings

Tailings sand can be widely used in construction concrete, especially in cement industry, ordinary concrete, cement products and other fields. Because the tailings itself is dry, no additional drying treatment is required, and the price is relatively cheap, so it has economic advantages to a certain extent. However, due to the fine particle size of tailings sand and some chemical residues, it needs to be treated according to the specific situation in the construction application to avoid adverse effects on the construction quality.

Mechanism sand and tailings sand have their own advantages and disadvantages, and play an important role in the construction industry. Through the reasonable selection and use of sand making equipment, the quality of tailings sand can be effectively improved, so that it can be more widely used in construction. Shibang Group is committed to providing high-quality sand making equipment and process solutions to contribute to the development of the construction industry.

Previous: SMP Crusher

Next: SMP Crusher

How to choose the equipment suitable for basalt sand making

How to choose the equipment suitable for basalt sand making How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme What are the basalt stone processing equipment

What are the basalt stone processing equipment How to choose the equipment suitable for basalt sand making

How to choose the equipment suitable for basalt sand making How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme What are the basalt stone processing equipment

What are the basalt stone processing equipment