As a widely used material in the construction field, basalt has unique advantages in concrete manufacturing due to its high hardness and compactness. It can not only reduce the weight of concrete, but also provide excellent sound insulation and heat in

As a widely used material in the construction field, basalt has unique advantages in concrete manufacturing due to its high hardness and compactness. It can not only reduce the weight of concrete, but also provide excellent sound insulation and heat insulation performance, especially suitable for lightweight concrete in high-rise buildings. However, in order to effectively make such hard basalt into machine-made sand that meets the standard, it is very important to choose the right sand making equipment.

Details of basalt sand making equipment

Characteristics and challenges of basalt

The Mohs hardness of basalt is between 5 and 7, and the compressive strength is as high as 300MPa, which means that it is difficult to break. Basalt has more pores and hard texture, although these characteristics make it a high quality concrete aggregate, but also put forward higher requirements for sand making equipment. Ordinary sand making machines are difficult to withstand the impact of such high-hardness materials, so more professional equipment is needed to deal with them.

recommend equipment: impact crusher

The impact crusher is an ideal choice for processing basalt due to its unique working principle. It not only has efficient sand making ability, but also can realize stone shaping at the same time, so that the finished sand particle size is uniform and the grain shape is excellent. The following are several advantages of impact crusher in basalt sand making:

Efficient sand making and shaping: the impact crusher adopts the principle of "stone hitting stone" or "stone striking iron", and realizes various crushing effects of stone through self-crushing. The discharge particle size of the equipment can be flexibly adjusted, and it can handle basalt sand and gravel with a particle size of 1-5mm, making it more suitable for concrete.

High output and low energy consumption: Compared with traditional sand making equipment, the output of impact crusher is increased by about 30%, and the energy consumption is low, which has higher economic benefits.

Strong wear resistance: The design of the throwing head of the impact crusher is optimized, and the material utilization rate is high. At the same time, the peripheral guard plate can be turned up and down to further extend the service life of the equipment.

Intelligent control: The equipment is equipped with intelligent thin oil lubrication system and hydraulic adjustment system, which can realize automatic control and fault alarm to ensure the stability of the equipment under long-term high-intensity work.

Other applicable equipment

In addition to the impact crusher, the following equipment can also be used in the multi-stage crushing process of basalt:

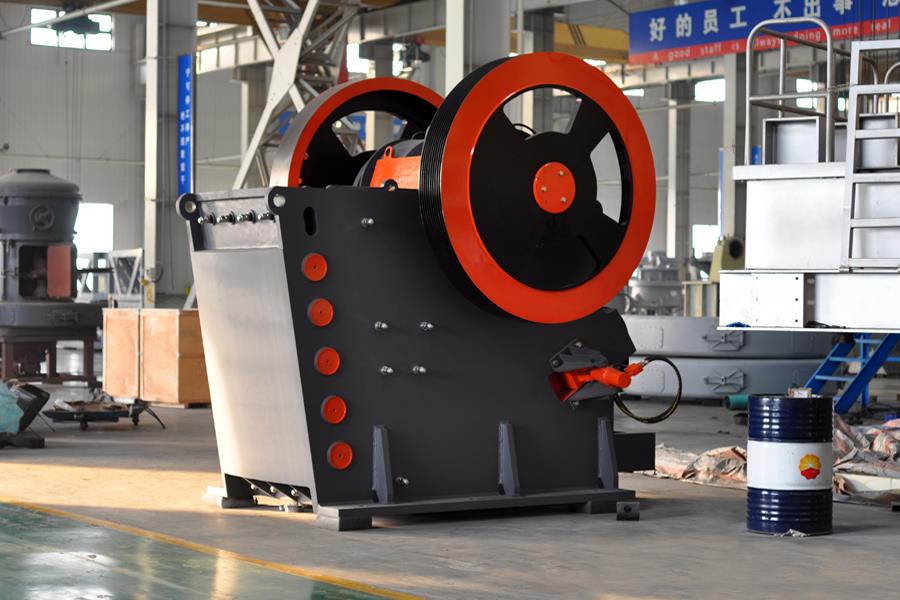

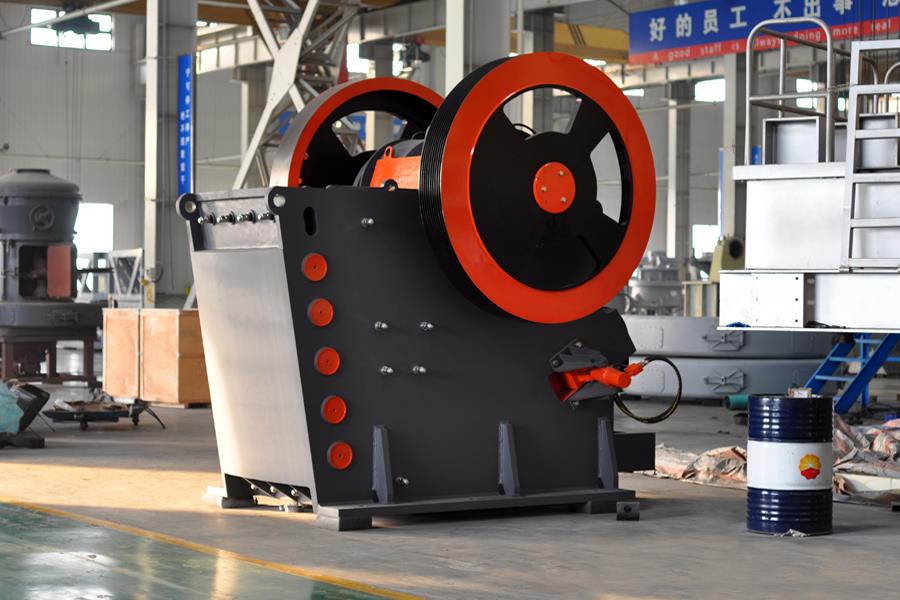

Jaw crusher: suitable for primary coarse crushing of basalt, capable of handling large-size stones, preparing for subsequent medium and fine crushing.

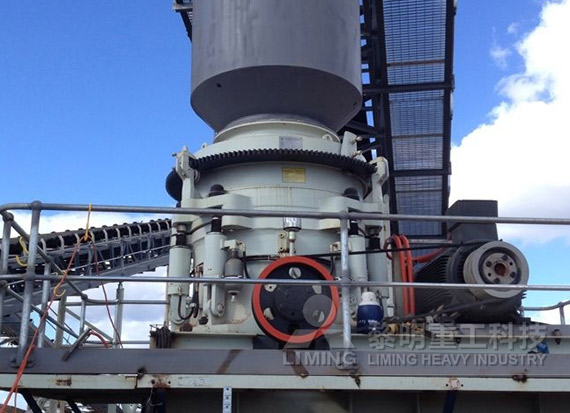

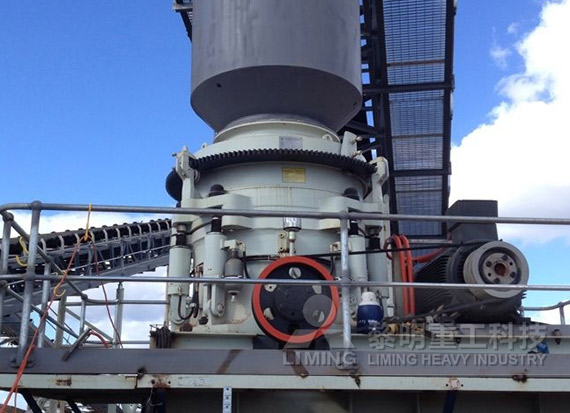

Cone crusher: specially designed for high hardness stone, suitable for medium and fine crushing processing of basalt, which can effectively reduce the wear of equipment and prolong the service life of equipment.

Configuration of Basalt Sand Production Line

Generally, the configuration of the basalt sand production line includes a jaw crusher, a cone crusher, an impact sand making machine, and auxiliary equipment such as a vibrating screen, a feeder, and a conveyor. This configuration can achieve efficient and stable production and ensure that the quality of basalt sand and gravel meets the standards of construction sand.

1 whole set of basalt sand equipment how much does it cost?

The price of the 1 set of basalt sand making equipment varies according to the configuration and manufacturer, and the market price ranges from hundreds of thousands to millions of yuan. The specific price needs to be determined according to the production demand, equipment model and configuration plan. It is recommended to contact the manufacturer for detailed consultation before purchasing.

Previous: SMP Crusher

Next: SMP Crusher

As a widely used material in the construction field, basalt has unique advantages in concrete manufacturing due to its high hardness and compactness. It can not only reduce the weight of concrete, but also provide excellent sound insulation and heat in

As a widely used material in the construction field, basalt has unique advantages in concrete manufacturing due to its high hardness and compactness. It can not only reduce the weight of concrete, but also provide excellent sound insulation and heat insulation performance, especially suitable for lightweight concrete in high-rise buildings. However, in order to effectively make such hard basalt into machine-made sand that meets the standard, it is very important to choose the right sand making equipment.

Details of basalt sand making equipment

Characteristics and challenges of basalt

The Mohs hardness of basalt is between 5 and 7, and the compressive strength is as high as 300MPa, which means that it is difficult to break. Basalt has more pores and hard texture, although these characteristics make it a high quality concrete aggregate, but also put forward higher requirements for sand making equipment. Ordinary sand making machines are difficult to withstand the impact of such high-hardness materials, so more professional equipment is needed to deal with them.

recommend equipment: impact crusher

The impact crusher is an ideal choice for processing basalt due to its unique working principle. It not only has efficient sand making ability, but also can realize stone shaping at the same time, so that the finished sand particle size is uniform and the grain shape is excellent. The following are several advantages of impact crusher in basalt sand making:

Efficient sand making and shaping: the impact crusher adopts the principle of "stone hitting stone" or "stone striking iron", and realizes various crushing effects of stone through self-crushing. The discharge particle size of the equipment can be flexibly adjusted, and it can handle basalt sand and gravel with a particle size of 1-5mm, making it more suitable for concrete.

High output and low energy consumption: Compared with traditional sand making equipment, the output of impact crusher is increased by about 30%, and the energy consumption is low, which has higher economic benefits.

Strong wear resistance: The design of the throwing head of the impact crusher is optimized, and the material utilization rate is high. At the same time, the peripheral guard plate can be turned up and down to further extend the service life of the equipment.

Intelligent control: The equipment is equipped with intelligent thin oil lubrication system and hydraulic adjustment system, which can realize automatic control and fault alarm to ensure the stability of the equipment under long-term high-intensity work.

Other applicable equipment

In addition to the impact crusher, the following equipment can also be used in the multi-stage crushing process of basalt:

Jaw crusher: suitable for primary coarse crushing of basalt, capable of handling large-size stones, preparing for subsequent medium and fine crushing.

Cone crusher: specially designed for high hardness stone, suitable for medium and fine crushing processing of basalt, which can effectively reduce the wear of equipment and prolong the service life of equipment.

Configuration of Basalt Sand Production Line

Generally, the configuration of the basalt sand production line includes a jaw crusher, a cone crusher, an impact sand making machine, and auxiliary equipment such as a vibrating screen, a feeder, and a conveyor. This configuration can achieve efficient and stable production and ensure that the quality of basalt sand and gravel meets the standards of construction sand.

1 whole set of basalt sand equipment how much does it cost?

The price of the 1 set of basalt sand making equipment varies according to the configuration and manufacturer, and the market price ranges from hundreds of thousands to millions of yuan. The specific price needs to be determined according to the production demand, equipment model and configuration plan. It is recommended to contact the manufacturer for detailed consultation before purchasing.

Previous: SMP Crusher

Next: SMP Crusher

How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme What are the basalt stone processing equipment

What are the basalt stone processing equipment How to choose stone crushing equipment

How to choose stone crushing equipment How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme

Annual output of 7 million tons of construction stone sand aggregate production line configuration scheme What are the basalt stone processing equipment

What are the basalt stone processing equipment How to choose stone crushing equipment

How to choose stone crushing equipment