The limestone crushing line consists of feeding, crushing and screening systems, and jaw and impact crushers are commonly used. The 500 tons/hour project in Yunnan selected Shibang equipment, which has high efficiency and stable production, excellent p

The limestone crushing line consists of feeding, crushing and screening systems, and jaw and impact crushers are commonly used. The 500 tons/hour project in Yunnan selected Shibang equipment, which has high efficiency and stable production, excellent particle shape, flexible design, strong stability, and provides localized services to ensure production efficiency and finished product quality.

With the rapid development of my country's economy, engineering construction is increasing, and the demand for stone production lines has also increased. As a widely used building material, the configuration of limestone crushing production line is the focus of customer attention. So when configuring a limestone production line, which crusher equipment should be selected?

Learn more about the selection of limestone crushing production line equipment

Choice of limestone crusher

Limestone (limestone) is a carbonate rock mainly distributed in North China and southern Northeast China. Limestone crushed stone is widely used, not only in building materials, but also in the production of concrete, lime slurry, silicate cement and road asphalt. Especially in the context of limited resource mining today, it has become a trend to use machine-made sand instead of natural sand in concrete. Limestone crushed stone that meets the crushing value standard can be used for bridge concrete. It has the characteristics of viscosity enhancement, lubrication, filling, etc., and has an enhancing effect on hydration.

Detailed explanation of limestone crushing production process

A complete limestone crushing production line usually consists of a feeding system, a crushing system and a screening system:

Feeding system: A vibrating feeder is used to evenly feed the stone into the crusher.

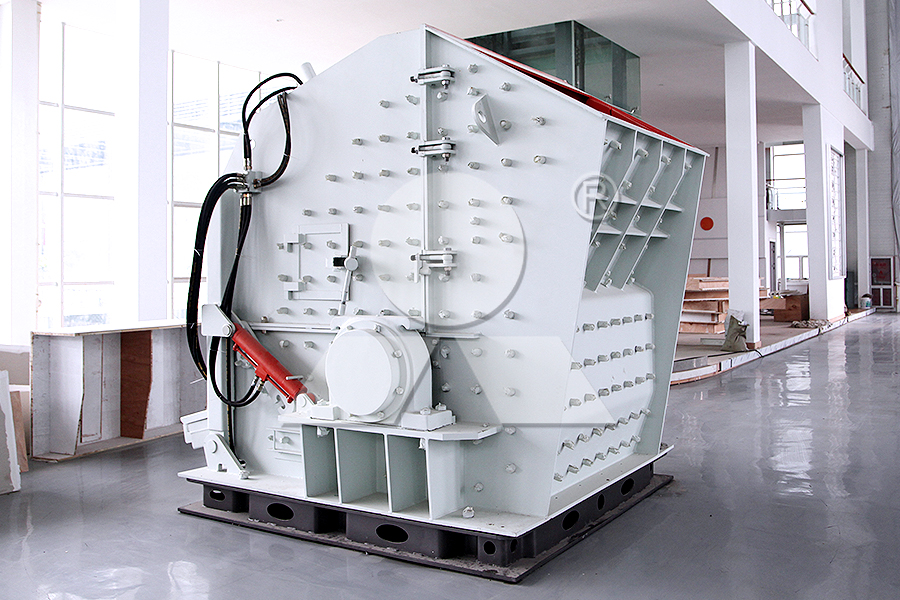

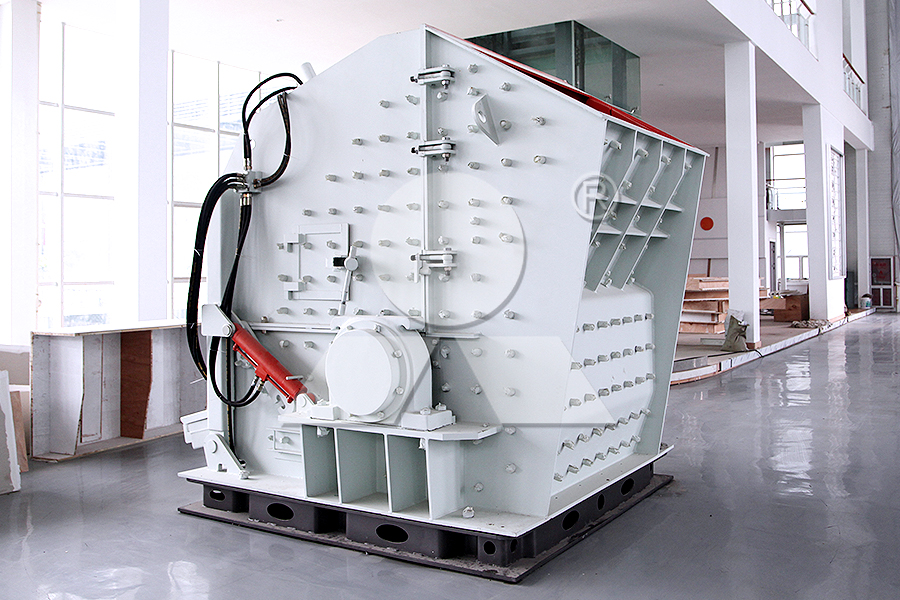

Crushing system: Generally, a two-stage crushing process is selected, including a jaw crusher for primary crushing and an impact crusher for secondary fine crushing.

Screening system: A circular vibrating screen is used to classify the material and screen out finished stone of different specifications. Unqualified stone is returned to the impact crusher for re-crushing to form a closed loop.

Case sharing: 500 tons per hour limestone production line in Yunnan

Project details:

Raw materials: limestone

Production capacity: 500 tons/hour

Discharge size: 0-5-10-20-31.5-80mm, etc.

Main purpose: for Kunming Steel Plant and nearby mixing stations

Main equipment: PEW European hydraulic jaw crusher, HST single-cylinder hydraulic cone crusher, PFW three-chamber impact crusher, etc.

This project uses high-efficiency equipment provided by Shibang Group, achieving high and stable production, which has been well received by customers and attracted many surrounding customers to visit and inspect.

Advantages of choosing Shibang Group equipment

Excellent finished product particle shape: The whole set of equipment from coarse crushing to fine crushing improves the quality of finished products.

Flexible design: The discharge specifications can be adjusted according to different needs to meet diversified production needs.

Strong stability: High-quality accessories and thin oil lubrication system improve the service life and stability of the equipment.

Localized service: Shibang Group has an office in Yunnan to provide considerate after-sales service.

Reasonable equipment configuration not only improves production efficiency, but also ensures the quality of finished products. Choosing Shibang Group's limestone crushing equipment will give you better return on investment and production experience.

Previous: SMP Crusher

Next: SMP Crusher

The limestone crushing line consists of feeding, crushing and screening systems, and jaw and impact crushers are commonly used. The 500 tons/hour project in Yunnan selected Shibang equipment, which has high efficiency and stable production, excellent p

The limestone crushing line consists of feeding, crushing and screening systems, and jaw and impact crushers are commonly used. The 500 tons/hour project in Yunnan selected Shibang equipment, which has high efficiency and stable production, excellent particle shape, flexible design, strong stability, and provides localized services to ensure production efficiency and finished product quality.

With the rapid development of my country's economy, engineering construction is increasing, and the demand for stone production lines has also increased. As a widely used building material, the configuration of limestone crushing production line is the focus of customer attention. So when configuring a limestone production line, which crusher equipment should be selected?

Learn more about the selection of limestone crushing production line equipment

Choice of limestone crusher

Limestone (limestone) is a carbonate rock mainly distributed in North China and southern Northeast China. Limestone crushed stone is widely used, not only in building materials, but also in the production of concrete, lime slurry, silicate cement and road asphalt. Especially in the context of limited resource mining today, it has become a trend to use machine-made sand instead of natural sand in concrete. Limestone crushed stone that meets the crushing value standard can be used for bridge concrete. It has the characteristics of viscosity enhancement, lubrication, filling, etc., and has an enhancing effect on hydration.

Detailed explanation of limestone crushing production process

A complete limestone crushing production line usually consists of a feeding system, a crushing system and a screening system:

Feeding system: A vibrating feeder is used to evenly feed the stone into the crusher.

Crushing system: Generally, a two-stage crushing process is selected, including a jaw crusher for primary crushing and an impact crusher for secondary fine crushing.

Screening system: A circular vibrating screen is used to classify the material and screen out finished stone of different specifications. Unqualified stone is returned to the impact crusher for re-crushing to form a closed loop.

Case sharing: 500 tons per hour limestone production line in Yunnan

Project details:

Raw materials: limestone

Production capacity: 500 tons/hour

Discharge size: 0-5-10-20-31.5-80mm, etc.

Main purpose: for Kunming Steel Plant and nearby mixing stations

Main equipment: PEW European hydraulic jaw crusher, HST single-cylinder hydraulic cone crusher, PFW three-chamber impact crusher, etc.

This project uses high-efficiency equipment provided by Shibang Group, achieving high and stable production, which has been well received by customers and attracted many surrounding customers to visit and inspect.

Advantages of choosing Shibang Group equipment

Excellent finished product particle shape: The whole set of equipment from coarse crushing to fine crushing improves the quality of finished products.

Flexible design: The discharge specifications can be adjusted according to different needs to meet diversified production needs.

Strong stability: High-quality accessories and thin oil lubrication system improve the service life and stability of the equipment.

Localized service: Shibang Group has an office in Yunnan to provide considerate after-sales service.

Reasonable equipment configuration not only improves production efficiency, but also ensures the quality of finished products. Choosing Shibang Group's limestone crushing equipment will give you better return on investment and production experience.

Previous: SMP Crusher

Next: SMP Crusher

How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete?

How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete? Can cone crusher process iron ore? How much does one cost?

Can cone crusher process iron ore? How much does one cost? What factors should be paid attention to when choosing large stone crusher equipment

What factors should be paid attention to when choosing large stone crusher equipment bauma China 2024 Shanghai

bauma China 2024 Shanghai Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making

Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete?

How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete? Can cone crusher process iron ore? How much does one cost?

Can cone crusher process iron ore? How much does one cost? What factors should be paid attention to when choosing large stone crusher equipment

What factors should be paid attention to when choosing large stone crusher equipment bauma China 2024 Shanghai

bauma China 2024 Shanghai Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making

Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making