"The secret of aluminum ore crushing process: from jaw crusher powerful crushing to flotation concentrate dehydration, nine processes create the core raw materials of national defense and military industry. Click to learn about the complete proces

"The secret of aluminum ore crushing process: from jaw crusher powerful crushing to flotation concentrate dehydration, nine processes create the core raw materials of national defense and military industry. Click to learn about the complete process chain of efficient extraction of aluminum concentrate."

Aluminum ore mainly includes diaspore, boehmite and gibbsite, all of which are ores for aluminum smelting. After being extracted by crushing, grinding, flotation and other processes, they can be used in defense, military industry, aerospace, communications, instrumentation and other fields.

Click to consult to understand the aluminum ore crushing process

Aluminum ore has different tastes, and it takes multiple process steps to extract aluminum concentrate from aluminum ore:

Raw material collection and pretreatment: Aluminum ore mined from the mine often needs to be pretreated before it is sent to the crushing equipment for crushing. This step aims to remove impurities that are too large in size or whose texture and shape are not suitable for direct crushing operations, so as to prepare for the smooth progress of subsequent crushing processes.

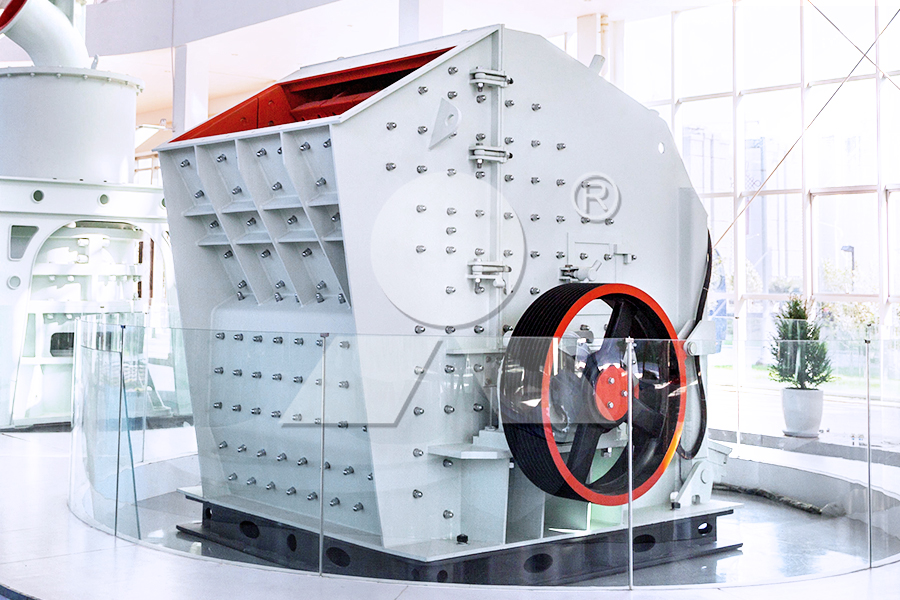

Primary crushing: Large pieces of aluminum ore will be first sent to the primary crushing equipment-jaw crusher. The jaw crusher has a deep V-shaped crushing chamber, which can provide strong crushing force. With these advantages, it can quickly crush large pieces of aluminum ore, reducing its size from large to medium, in preparation for subsequent processing.

Medium and fine crushing: After primary crushing, aluminum ore will enter the medium and fine crushing stage. Aluminum ore has a high hardness and belongs to metal ore. Cone crusher is generally used for medium and fine crushing. In actual operation, a combination of single-cylinder cone crusher and multi-cylinder cone crusher can be used to improve crushing efficiency and effect.

Screening: The crushed aluminum ore needs to be screened to separate the ore that meets the particle size requirements and the ore that needs to be reworked.

Conveying: In the production line, the belt conveyor is responsible for transporting the processed ore to the next process or storage area. This conveying method can achieve continuity and automation of the production process and improve production efficiency.

Grinding: After crushing, the aluminum ore that meets the grinding requirements is sent to the grinding mill to grind the ore into a fine powder state in preparation for the subsequent beneficiation process.

Flotation: Flotation machines are used to separate aluminum ore powder to obtain high-grade aluminum concentrate. During the flotation process, valuable minerals are separated from non-valuable minerals by adding chemical agents.

Drying: The aluminum concentrate after flotation usually contains more water and needs to be dried and dehydrated by a dryer.

Finished product collection and storage: The aluminum ore finished products processed by the above process will be collected and stored, waiting for subsequent transportation or further processing.

Previous: SMP Crusher

Next: SMP Crusher

"The secret of aluminum ore crushing process: from jaw crusher powerful crushing to flotation concentrate dehydration, nine processes create the core raw materials of national defense and military industry. Click to learn about the complete proces

"The secret of aluminum ore crushing process: from jaw crusher powerful crushing to flotation concentrate dehydration, nine processes create the core raw materials of national defense and military industry. Click to learn about the complete process chain of efficient extraction of aluminum concentrate."

Aluminum ore mainly includes diaspore, boehmite and gibbsite, all of which are ores for aluminum smelting. After being extracted by crushing, grinding, flotation and other processes, they can be used in defense, military industry, aerospace, communications, instrumentation and other fields.

Click to consult to understand the aluminum ore crushing process

Aluminum ore has different tastes, and it takes multiple process steps to extract aluminum concentrate from aluminum ore:

Raw material collection and pretreatment: Aluminum ore mined from the mine often needs to be pretreated before it is sent to the crushing equipment for crushing. This step aims to remove impurities that are too large in size or whose texture and shape are not suitable for direct crushing operations, so as to prepare for the smooth progress of subsequent crushing processes.

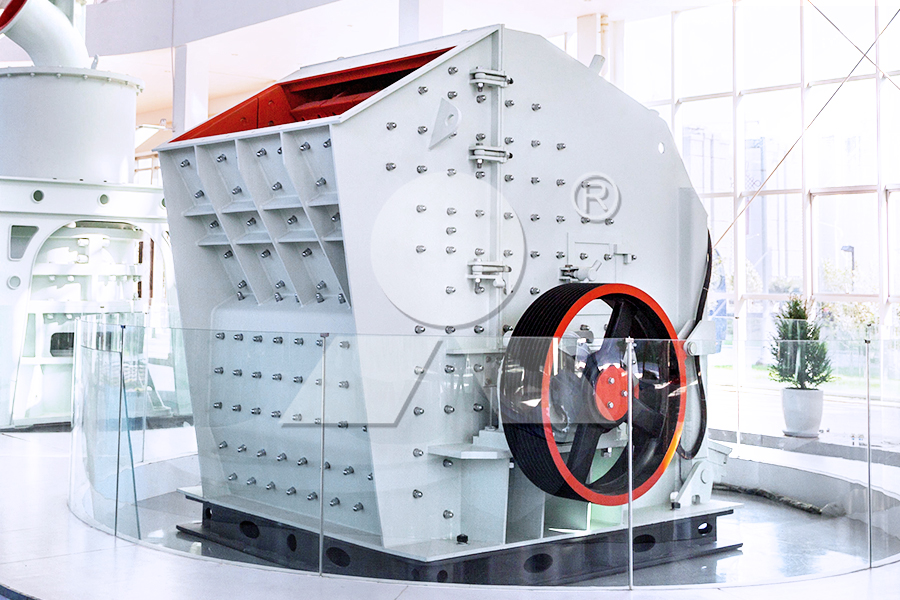

Primary crushing: Large pieces of aluminum ore will be first sent to the primary crushing equipment-jaw crusher. The jaw crusher has a deep V-shaped crushing chamber, which can provide strong crushing force. With these advantages, it can quickly crush large pieces of aluminum ore, reducing its size from large to medium, in preparation for subsequent processing.

Medium and fine crushing: After primary crushing, aluminum ore will enter the medium and fine crushing stage. Aluminum ore has a high hardness and belongs to metal ore. Cone crusher is generally used for medium and fine crushing. In actual operation, a combination of single-cylinder cone crusher and multi-cylinder cone crusher can be used to improve crushing efficiency and effect.

Screening: The crushed aluminum ore needs to be screened to separate the ore that meets the particle size requirements and the ore that needs to be reworked.

Conveying: In the production line, the belt conveyor is responsible for transporting the processed ore to the next process or storage area. This conveying method can achieve continuity and automation of the production process and improve production efficiency.

Grinding: After crushing, the aluminum ore that meets the grinding requirements is sent to the grinding mill to grind the ore into a fine powder state in preparation for the subsequent beneficiation process.

Flotation: Flotation machines are used to separate aluminum ore powder to obtain high-grade aluminum concentrate. During the flotation process, valuable minerals are separated from non-valuable minerals by adding chemical agents.

Drying: The aluminum concentrate after flotation usually contains more water and needs to be dried and dehydrated by a dryer.

Finished product collection and storage: The aluminum ore finished products processed by the above process will be collected and stored, waiting for subsequent transportation or further processing.

Previous: SMP Crusher

Next: SMP Crusher

Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction

Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction How to configure a 2000-ton-per-day construction waste crushing production line

How to configure a 2000-ton-per-day construction waste crushing production line Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction

Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction How to configure a 2000-ton-per-day construction waste crushing production line

How to configure a 2000-ton-per-day construction waste crushing production line