Calcium carbonate is our common limestone, marble, dolomite is a common industrial raw materials, calcium carbonate applications need to be ground before processing, often used calcium carbonate mill, according to the number of different grinding

Calcium carbonate is our common limestone, marble, dolomite is a common industrial raw materials, calcium carbonate applications need to be ground before processing, often used calcium carbonate mill, according to the number of different grinding, you can choose raymond machine, ultrafine mill, grinding mill, high pressure grinding rollers and so on. Processing of calcium carbonate raw materials, also need to follow the output and the required particle size selection of grinding equipment, grinding mill grinding accuracy depends on the quality and efficiency of the mill itself. Then to make a good quality grinding machine equipment, advanced calcium powder grinding machine, to keep pace with the times and constantly innovate, so that the grinding equipment has its own foothold.

1, processing calcium carbonate grinding equipment

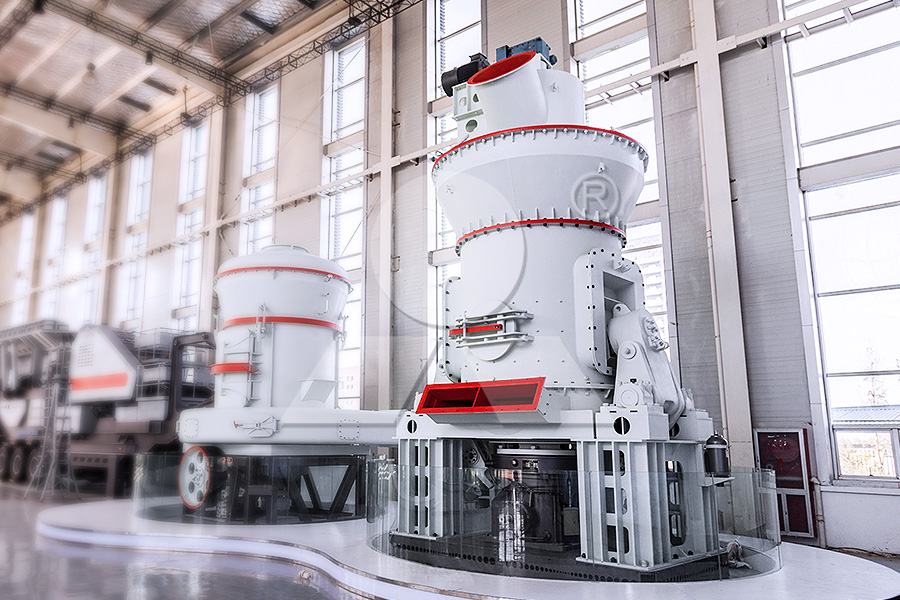

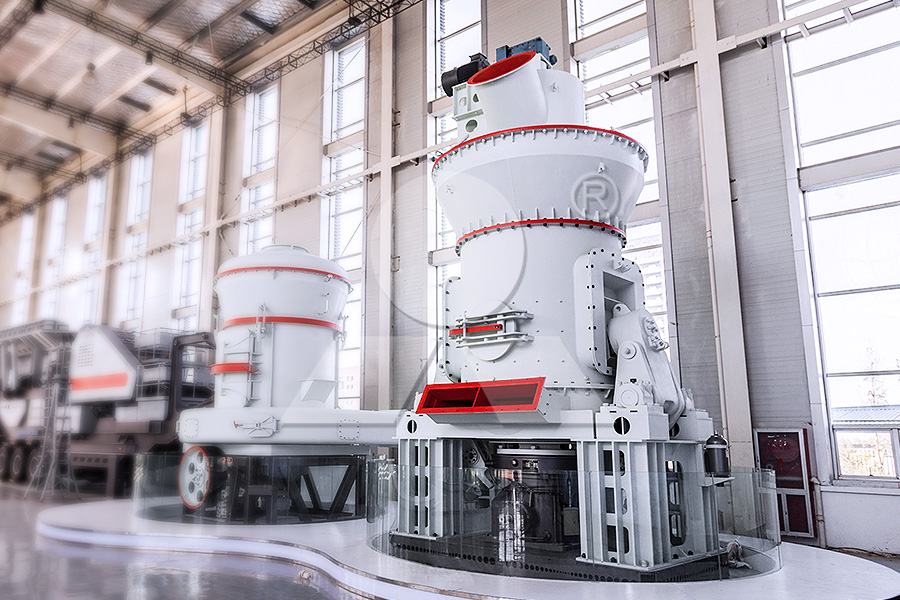

According to the grinding principle, structure and grinding mesh, grinding equipment for processing materials can be divided into Raymond mill, ultrafine vertical mill, ultrafine mill, European version of the coarse powder mill.

2, calcium carbonate ultrafine mill grinding principle

Ultrafine mill belongs to the vertical structure, the internal configuration of the grinding rollers, grinding ring device, etc., when working, the host motor through the reducer to drive the spindle and rotary disk rotation, the edge of the rotary disk roller pins to drive dozens of grinding rollers in the grinding ring rolling in the raceway. The material under the action of centrifugal force dispersed to the circular periphery, and fall into the grinding ring raceway by the ring roller impact, rolling, grinding, after three layers of ring processing into powder, high-pressure fan through the suction effect of the external air into the machine, and will be crushed materials into the powder selector. The rotating impeller in the powder selector makes the coarse material fall back to regrind, and the fine powder that meets the requirements enters the cyclone collector with the airflow and is discharged by the discharge valve in the lower part of the finished product, while the airflow with a small amount of fine dust passes through the pulse dust collector and is discharged through the fan and the muffler.

3、How does calcium carbonate grinding equipment change in quality?

Calcium carbonate grinding equipment how to rise qualitative changes, to improve the quality of change from the spirit of the country, the traditional sense of craftsmanship is synonymous with skill, quality, reputation, has always been the likes of everyone, respect and esteem, and the modern sense of craftsmanship, is to stand in the international perspective to the level of technical innovation; the transformation of the machine, according to the user's needs to the corresponding changes in the calcium carbonate mill manufacturer, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country. For calcium carbonate mill manufacturer, the spirit of great national craftsmanship embodied in the control of the quality of the machine, the rigor of the production process, technological innovation, for the user's responsibility, etc., only full of great national craftsmanship in the production of calcium carbonate mill in order to have a high quality, high performance, the equipment in order to get the quality of the sublimation.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

Calcium carbonate is our common limestone, marble, dolomite is a common industrial raw materials, calcium carbonate applications need to be ground before processing, often used calcium carbonate mill, according to the number of different grinding

Calcium carbonate is our common limestone, marble, dolomite is a common industrial raw materials, calcium carbonate applications need to be ground before processing, often used calcium carbonate mill, according to the number of different grinding, you can choose raymond machine, ultrafine mill, grinding mill, high pressure grinding rollers and so on. Processing of calcium carbonate raw materials, also need to follow the output and the required particle size selection of grinding equipment, grinding mill grinding accuracy depends on the quality and efficiency of the mill itself. Then to make a good quality grinding machine equipment, advanced calcium powder grinding machine, to keep pace with the times and constantly innovate, so that the grinding equipment has its own foothold.

1, processing calcium carbonate grinding equipment

According to the grinding principle, structure and grinding mesh, grinding equipment for processing materials can be divided into Raymond mill, ultrafine vertical mill, ultrafine mill, European version of the coarse powder mill.

2, calcium carbonate ultrafine mill grinding principle

Ultrafine mill belongs to the vertical structure, the internal configuration of the grinding rollers, grinding ring device, etc., when working, the host motor through the reducer to drive the spindle and rotary disk rotation, the edge of the rotary disk roller pins to drive dozens of grinding rollers in the grinding ring rolling in the raceway. The material under the action of centrifugal force dispersed to the circular periphery, and fall into the grinding ring raceway by the ring roller impact, rolling, grinding, after three layers of ring processing into powder, high-pressure fan through the suction effect of the external air into the machine, and will be crushed materials into the powder selector. The rotating impeller in the powder selector makes the coarse material fall back to regrind, and the fine powder that meets the requirements enters the cyclone collector with the airflow and is discharged by the discharge valve in the lower part of the finished product, while the airflow with a small amount of fine dust passes through the pulse dust collector and is discharged through the fan and the muffler.

3、How does calcium carbonate grinding equipment change in quality?

Calcium carbonate grinding equipment how to rise qualitative changes, to improve the quality of change from the spirit of the country, the traditional sense of craftsmanship is synonymous with skill, quality, reputation, has always been the likes of everyone, respect and esteem, and the modern sense of craftsmanship, is to stand in the international perspective to the level of technical innovation; the transformation of the machine, according to the user's needs to the corresponding changes in the calcium carbonate mill manufacturer, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country, the big country. For calcium carbonate mill manufacturer, the spirit of great national craftsmanship embodied in the control of the quality of the machine, the rigor of the production process, technological innovation, for the user's responsibility, etc., only full of great national craftsmanship in the production of calcium carbonate mill in order to have a high quality, high performance, the equipment in order to get the quality of the sublimation.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

How to select stone grinding machine equipment

How to select stone grinding machine equipment Ore Raymond Mill, Ore Superfine Mill Price

Ore Raymond Mill, Ore Superfine Mill Price 1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh

1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh What are the easily overlooked faults of Raymond Mill

What are the easily overlooked faults of Raymond Mill Raymond mill choose different discharge fineness of the stone is not the same yield

Raymond mill choose different discharge fineness of the stone is not the same yield How to select stone grinding machine equipment

How to select stone grinding machine equipment Ore Raymond Mill, Ore Superfine Mill Price

Ore Raymond Mill, Ore Superfine Mill Price 1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh

1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh What are the easily overlooked faults of Raymond Mill

What are the easily overlooked faults of Raymond Mill Raymond mill choose different discharge fineness of the stone is not the same yield

Raymond mill choose different discharge fineness of the stone is not the same yield