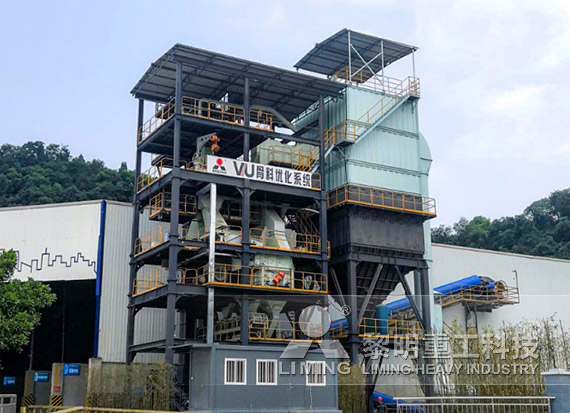

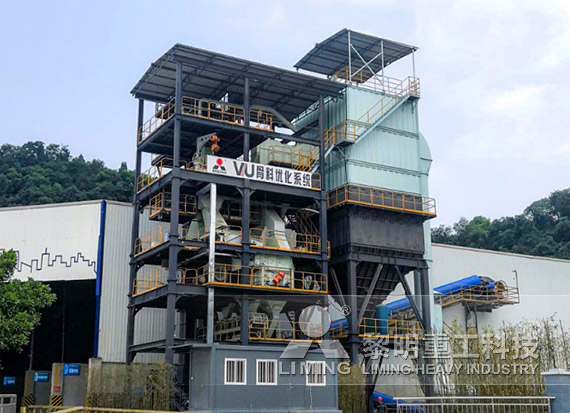

Impact sand making machine is a widely used sand making machine equipment. The bearings, rotors, impact blocks and impellers in the equipment are all important parts. Daily maintenance is very important to improve the service life of the impact crusher

Impact sand making machine is a widely used sand making machine equipment. The bearings, rotors, impact blocks and impellers in the equipment are all important parts. Daily maintenance is very important to improve the service life of the impact crusher.

Click here to learn about impact sand making machine

1. Bearings

The bearings support the entire load of the machine, so they need to be lubricated regularly and ensure good sealing. To maintain the equipment, the impact crusher should be lubricated after 400 hours of operation, the bearings need to be cleaned after 2000 hours, and the new bearings should be replaced according to the usage after 7200 hours to ensure smooth operation of the equipment.

2. Rotor

When the rotor runs at high speed, its top, inner side and lower edge will wear. It is necessary to check the machine status daily and check the tightness of the V-belt regularly. If it is too loose, it needs to be adjusted in time to ensure that the belt is correctly selected to prevent the rotor from aggravating wear due to unbalanced centrifugal force when rotating, and to ensure the normal operation of the rotor and bearings.

3. Impact block

Impact block wear may be related to improper material selection, unreasonable structural parameters or inconsistent material properties. Highly wear-resistant materials should be selected and the configuration of the machine and impact block should be consistent. Too high material hardness will accelerate wear, so moderate hardness materials need to be selected. At the same time, the gap between the impact block and the impact plate needs to be adjusted to reduce wear and extend service life.

4. Impeller

Observe whether the impeller keeps rotating counterclockwise from the inlet of the sand making machine. If not, the motor wiring needs to be adjusted to ensure uniform and continuous feeding, and the feeding particle size meets the requirements to prevent large materials from damaging the impeller. Stop feeding before shutting down to avoid crushing the impeller. Check the impeller device regularly and replace it in time if it is worn to ensure normal production.

Previous: SMP Crusher

Next: SMP Crusher

Impact sand making machine is a widely used sand making machine equipment. The bearings, rotors, impact blocks and impellers in the equipment are all important parts. Daily maintenance is very important to improve the service life of the impact crusher

Impact sand making machine is a widely used sand making machine equipment. The bearings, rotors, impact blocks and impellers in the equipment are all important parts. Daily maintenance is very important to improve the service life of the impact crusher.

Click here to learn about impact sand making machine

1. Bearings

The bearings support the entire load of the machine, so they need to be lubricated regularly and ensure good sealing. To maintain the equipment, the impact crusher should be lubricated after 400 hours of operation, the bearings need to be cleaned after 2000 hours, and the new bearings should be replaced according to the usage after 7200 hours to ensure smooth operation of the equipment.

2. Rotor

When the rotor runs at high speed, its top, inner side and lower edge will wear. It is necessary to check the machine status daily and check the tightness of the V-belt regularly. If it is too loose, it needs to be adjusted in time to ensure that the belt is correctly selected to prevent the rotor from aggravating wear due to unbalanced centrifugal force when rotating, and to ensure the normal operation of the rotor and bearings.

3. Impact block

Impact block wear may be related to improper material selection, unreasonable structural parameters or inconsistent material properties. Highly wear-resistant materials should be selected and the configuration of the machine and impact block should be consistent. Too high material hardness will accelerate wear, so moderate hardness materials need to be selected. At the same time, the gap between the impact block and the impact plate needs to be adjusted to reduce wear and extend service life.

4. Impeller

Observe whether the impeller keeps rotating counterclockwise from the inlet of the sand making machine. If not, the motor wiring needs to be adjusted to ensure uniform and continuous feeding, and the feeding particle size meets the requirements to prevent large materials from damaging the impeller. Stop feeding before shutting down to avoid crushing the impeller. Check the impeller device regularly and replace it in time if it is worn to ensure normal production.

Previous: SMP Crusher

Next: SMP Crusher

How to clean the inside of cone crusher

How to clean the inside of cone crusher What are the differences between coarse jaw crusher and fine jaw crusher?

What are the differences between coarse jaw crusher and fine jaw crusher? Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone

Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone Which equipment is best for weathered stone crushing and sand making? How much does it cost?

Which equipment is best for weathered stone crushing and sand making? How much does it cost? What equipment is needed to produce sand and gravel? How much does one cost?

What equipment is needed to produce sand and gravel? How much does one cost? How to clean the inside of cone crusher

How to clean the inside of cone crusher What are the differences between coarse jaw crusher and fine jaw crusher?

What are the differences between coarse jaw crusher and fine jaw crusher? Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone

Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone Which equipment is best for weathered stone crushing and sand making? How much does it cost?

Which equipment is best for weathered stone crushing and sand making? How much does it cost? What equipment is needed to produce sand and gravel? How much does one cost?

What equipment is needed to produce sand and gravel? How much does one cost?