Liming Heavy Industry's machine-made sand production line achieves energy conservation and emission reduction through the following ways:Environmental protection equipment configuration: The production line is equipped with dust

Liming Heavy Industry's machine-made sand production line achieves energy conservation and emission reduction through the following ways:

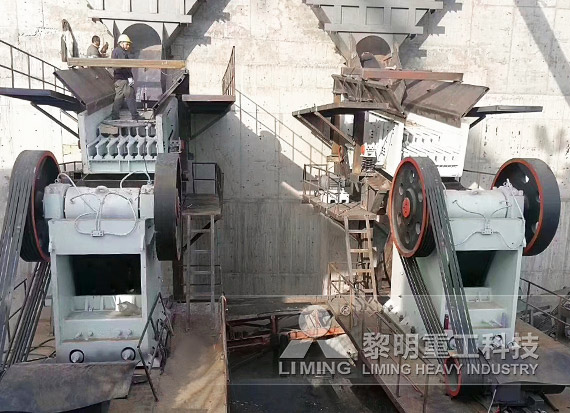

Environmental protection equipment configuration: The production line is equipped with dust removal equipment to effectively treat dust and reduce dust emissions. At the same time, a closed structure is adopted to reduce dust escape and improve the operating environment. For example, in a green mining project in the northwest, the production line is equipped with 26 sets of dust removal equipment, which adopts a fully enclosed design, and the dust emission concentration is far lower than the national standard.

Air self-circulation system: A novel air self-circulation system is adopted to reduce the external air volume by 60%-75%, control dust generation, and reduce pollution.

Atomization nozzle design: The production line adopts a full-line atomization nozzle design to reduce dust dispersion, avoid personal injury to on-site workers, and further control dust pollution.

Optimize the feeding system: Improve the feeding system from the source, reduce dust emissions, and reduce the environmental impact during the production process.

Reserve dust removal and noise reduction interface: The production line reserves interfaces for installing various specifications of dust removal and noise reduction equipment, which can control dust emissions and noise release in real time as needed to ensure environmental protection standards.

High-efficiency and energy-saving equipment: The sand making machines such as VSI5X and VSI6X developed by Liming Heavy Industry use imported wear-resistant materials and international brand bearings to reduce energy consumption, increase equipment service life, and reduce resource consumption.

Process optimization: The production line adopts the advanced "two-stage crushing and two-stage screening" process to achieve efficient utilization of ore, and the comprehensive utilization rate of resources reaches more than 95%, reducing waste.

Water resource recycling: Establish a sewage sedimentation tank to precipitate sand washing sewage, realize the recycling of water resources, and reduce water consumption.

Digital management platform: Establish a digital management platform for mines to monitor production, safety, environmental protection and other links in real time, optimize management efficiency, and reduce unnecessary energy consumption and emissions.

Previous: SMP Crusher

Next: SMP Crusher

Liming Heavy Industry's machine-made sand production line achieves energy conservation and emission reduction through the following ways:Environmental protection equipment configuration: The production line is equipped with dust

Liming Heavy Industry's machine-made sand production line achieves energy conservation and emission reduction through the following ways:

Environmental protection equipment configuration: The production line is equipped with dust removal equipment to effectively treat dust and reduce dust emissions. At the same time, a closed structure is adopted to reduce dust escape and improve the operating environment. For example, in a green mining project in the northwest, the production line is equipped with 26 sets of dust removal equipment, which adopts a fully enclosed design, and the dust emission concentration is far lower than the national standard.

Air self-circulation system: A novel air self-circulation system is adopted to reduce the external air volume by 60%-75%, control dust generation, and reduce pollution.

Atomization nozzle design: The production line adopts a full-line atomization nozzle design to reduce dust dispersion, avoid personal injury to on-site workers, and further control dust pollution.

Optimize the feeding system: Improve the feeding system from the source, reduce dust emissions, and reduce the environmental impact during the production process.

Reserve dust removal and noise reduction interface: The production line reserves interfaces for installing various specifications of dust removal and noise reduction equipment, which can control dust emissions and noise release in real time as needed to ensure environmental protection standards.

High-efficiency and energy-saving equipment: The sand making machines such as VSI5X and VSI6X developed by Liming Heavy Industry use imported wear-resistant materials and international brand bearings to reduce energy consumption, increase equipment service life, and reduce resource consumption.

Process optimization: The production line adopts the advanced "two-stage crushing and two-stage screening" process to achieve efficient utilization of ore, and the comprehensive utilization rate of resources reaches more than 95%, reducing waste.

Water resource recycling: Establish a sewage sedimentation tank to precipitate sand washing sewage, realize the recycling of water resources, and reduce water consumption.

Digital management platform: Establish a digital management platform for mines to monitor production, safety, environmental protection and other links in real time, optimize management efficiency, and reduce unnecessary energy consumption and emissions.

Previous: SMP Crusher

Next: SMP Crusher

How to reduce noise in Liming Heavy Industry s machine-made sand production line

How to reduce noise in Liming Heavy Industry s machine-made sand production line What are the noise reduction measures for machine-made sand production lines and how to implement them for better results?

What are the noise reduction measures for machine-made sand production lines and how to implement them for better results? Introduction to Liming Heavy Industry Sand Making Production Line: A New Model of Efficient, Intelligent and Environmentally Friendly Sand Making

Introduction to Liming Heavy Industry Sand Making Production Line: A New Model of Efficient, Intelligent and Environmentally Friendly Sand Making Liming Heavy Industry Sand Production Line: Injecting Strong Power into Sand and Gravel Projects

Liming Heavy Industry Sand Production Line: Injecting Strong Power into Sand and Gravel Projects Liming Heavy Industry: A hard-core partner in the field of crushing and sand making, enabling various stone projects to take off

Liming Heavy Industry: A hard-core partner in the field of crushing and sand making, enabling various stone projects to take off How to reduce noise in Liming Heavy Industry s machine-made sand production line

How to reduce noise in Liming Heavy Industry s machine-made sand production line What are the noise reduction measures for machine-made sand production lines and how to implement them for better results?

What are the noise reduction measures for machine-made sand production lines and how to implement them for better results? Introduction to Liming Heavy Industry Sand Making Production Line: A New Model of Efficient, Intelligent and Environmentally Friendly Sand Making

Introduction to Liming Heavy Industry Sand Making Production Line: A New Model of Efficient, Intelligent and Environmentally Friendly Sand Making Liming Heavy Industry Sand Production Line: Injecting Strong Power into Sand and Gravel Projects

Liming Heavy Industry Sand Production Line: Injecting Strong Power into Sand and Gravel Projects Liming Heavy Industry: A hard-core partner in the field of crushing and sand making, enabling various stone projects to take off

Liming Heavy Industry: A hard-core partner in the field of crushing and sand making, enabling various stone projects to take off