Wugang adheres to a green and sustainable development strategy, integrating modularization, industrialization, park-based development, intelligentization, and environmentally friendly design to achieve simultaneous mining and ecological restoration. Th

Wugang adheres to a green and sustainable development strategy, integrating modularization, industrialization, park-based development, intelligentization, and environmentally friendly design to achieve simultaneous mining and ecological restoration. This project, with an investment of 1.68 billion yuan, covers 840 acres and boasts ore reserves exceeding 50 million tons, with a planned annual production capacity of 5 million tons. It is being fully constructed by Shibang Group using an EPC model, aiming to create a benchmark for green transformation in the industry.

Click here to inquire about the construction plan for the green and environmentally friendly sand and gravel production line.

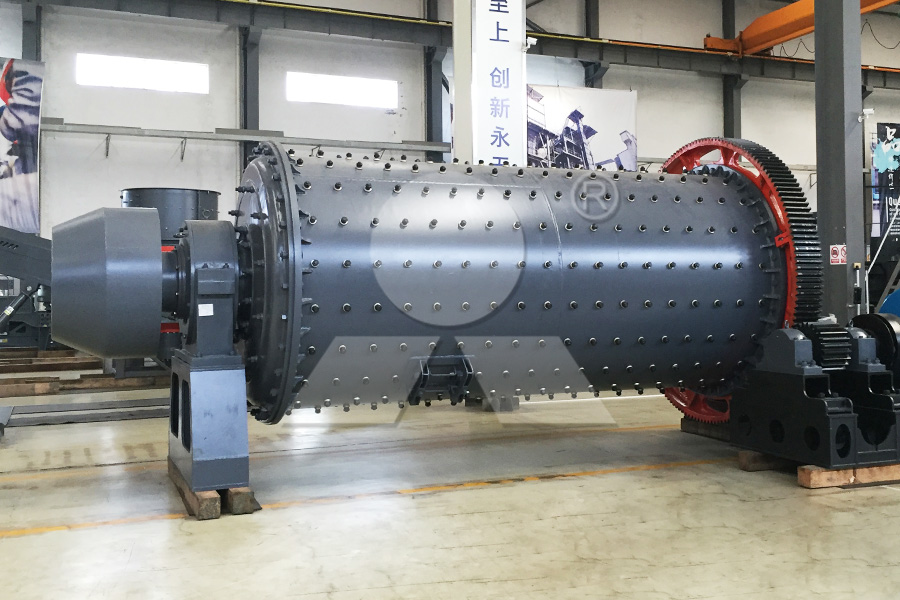

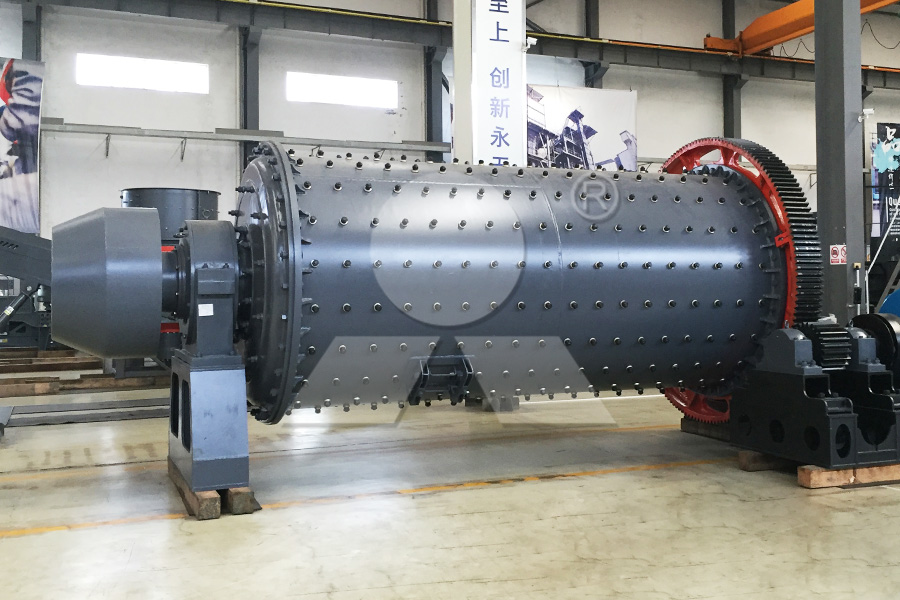

This project adopts a highly efficient crushing and shaping process, including three stages of crushing and final shaping and sand making. The core equipment consists of two C6X jaw crushers from Shibang Heavy Industry for initial coarse crushing, supplemented by two vibrating feeders for precise material feeding.

Two HST single-cylinder and four HPT multi-cylinder cone crushers then perform medium and fine crushing to ensure uniform particle size. Twelve screens provide fine grading, and four VSI6X shaping and sand making machines complete the high-quality shaping of the sand. The overall process is smooth, and the advanced equipment configuration effectively improves production efficiency and finished product quality.

Previously, the client had purchased mobile crushing plants from Shibang. This time, the two parties collaborated again, with even greater synergy and smoother progress. In the initial design phase of the production line, Shibang Group placed particular emphasis on green environmental protection and intelligent automation, fully considering site conditions and rationally arranging the production line layout.

Previous: SMP Crusher

Next: SMP Crusher

Wugang adheres to a green and sustainable development strategy, integrating modularization, industrialization, park-based development, intelligentization, and environmentally friendly design to achieve simultaneous mining and ecological restoration. Th

Wugang adheres to a green and sustainable development strategy, integrating modularization, industrialization, park-based development, intelligentization, and environmentally friendly design to achieve simultaneous mining and ecological restoration. This project, with an investment of 1.68 billion yuan, covers 840 acres and boasts ore reserves exceeding 50 million tons, with a planned annual production capacity of 5 million tons. It is being fully constructed by Shibang Group using an EPC model, aiming to create a benchmark for green transformation in the industry.

Click here to inquire about the construction plan for the green and environmentally friendly sand and gravel production line.

This project adopts a highly efficient crushing and shaping process, including three stages of crushing and final shaping and sand making. The core equipment consists of two C6X jaw crushers from Shibang Heavy Industry for initial coarse crushing, supplemented by two vibrating feeders for precise material feeding.

Two HST single-cylinder and four HPT multi-cylinder cone crushers then perform medium and fine crushing to ensure uniform particle size. Twelve screens provide fine grading, and four VSI6X shaping and sand making machines complete the high-quality shaping of the sand. The overall process is smooth, and the advanced equipment configuration effectively improves production efficiency and finished product quality.

Previously, the client had purchased mobile crushing plants from Shibang. This time, the two parties collaborated again, with even greater synergy and smoother progress. In the initial design phase of the production line, Shibang Group placed particular emphasis on green environmental protection and intelligent automation, fully considering site conditions and rationally arranging the production line layout.

Previous: SMP Crusher

Next: SMP Crusher

Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing

Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing Is the Shibang HST750 cone crusher any good?

Is the Shibang HST750 cone crusher any good? Configuration scheme for a 10,000-ton-per-day stone production line

Configuration scheme for a 10,000-ton-per-day stone production line Tracked crushing equipment: the smart choice for hard and soft rock.

Tracked crushing equipment: the smart choice for hard and soft rock. How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour?

How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour? Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing

Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing Is the Shibang HST750 cone crusher any good?

Is the Shibang HST750 cone crusher any good? Configuration scheme for a 10,000-ton-per-day stone production line

Configuration scheme for a 10,000-ton-per-day stone production line Tracked crushing equipment: the smart choice for hard and soft rock.

Tracked crushing equipment: the smart choice for hard and soft rock. How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour?

How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour?