In the fields of mining, sand and gravel aggregate production, etc., coarse crushing equipment, as the "first checkpoint" of the crushing production line, undertakes the key task of initially crushing large pieces of raw stone into smaller pa

In the fields of mining, sand and gravel aggregate production, etc., coarse crushing equipment, as the "first checkpoint" of the crushing production line, undertakes the key task of initially crushing large pieces of raw stone into smaller particles. Choosing an efficient and durable coarse crushing equipment can not only improve the overall production efficiency, but also reduce operating costs.

1. The important role of coarse crushing equipment in the field of mining machinery crushing

1. Rapid processing of large pieces of raw materials: Coarse crushing equipment can quickly crush the mined raw ore (such as granite, limestone, etc.) to a particle size suitable for medium and fine crushing, laying the foundation for subsequent processes.

2. Reduce energy consumption and cost: Pre-reducing the volume of materials through the coarse crushing link can greatly reduce the load of medium and fine crushing equipment, extend the life of the equipment, and save energy.

3. Ensure the continuity of the production line: Stable coarse crushing capacity is the core of the efficient operation of the production line, avoiding the shutdown of the entire line due to equipment failure.

2. How to choose a suitable coarse crushing equipment? Three tricks to get it done!

The first step: clarify material characteristics and production requirements

Material hardness and composition: high-hardness ores (such as granite) require equipment with high compressive strength (such as jaw crushers); sticky materials require anti-blocking design.

Capacity requirements: select matching models according to the hourly processing volume (such as 100-1500 tons) to avoid "big horses pulling small carts" or overload operation.

Discharge particle size requirements: the size of the material after coarse crushing needs to be adapted to the subsequent process (such as secondary crushing or direct screening).

The second step: pay attention to equipment performance and energy consumption

Crushing ratio: high crushing ratio equipment can reduce the number of crushing stages and save investment costs.

Wear resistance and maintenance convenience: key components (such as jaw plates and rotors) are made of high-strength alloy materials, and the structural design is easy to repair.

Energy consumption and environmental protection: choose energy-saving motors and low-noise designs to meet the trend of green production.

The third step: examine brand technology and service guarantee

Give priority to brands with mature technology and good reputation to ensure equipment operation stability and after-sales support capabilities.

3. Common coarse crushing equipment types

Jaw crusher - the first choice for coarse crushing of medium and high hardness materials

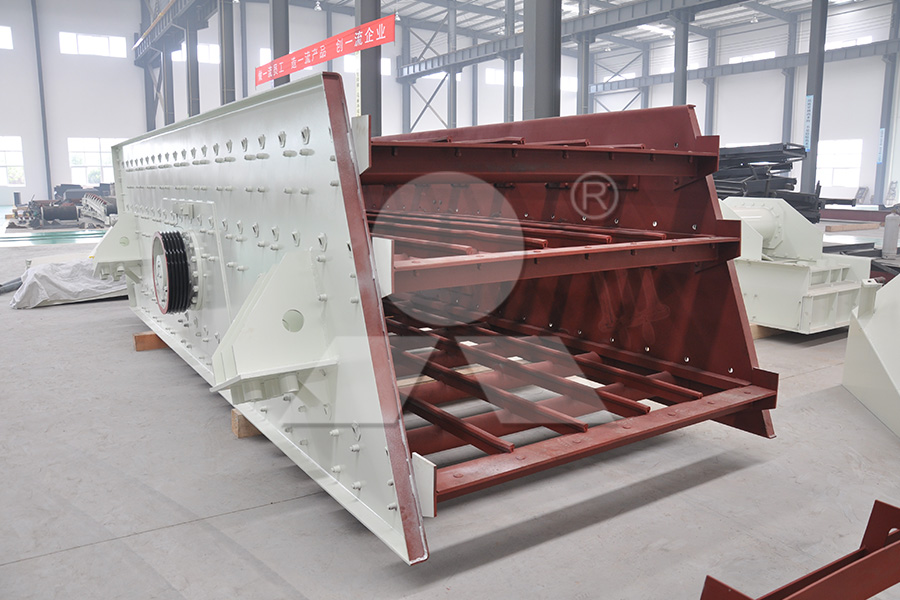

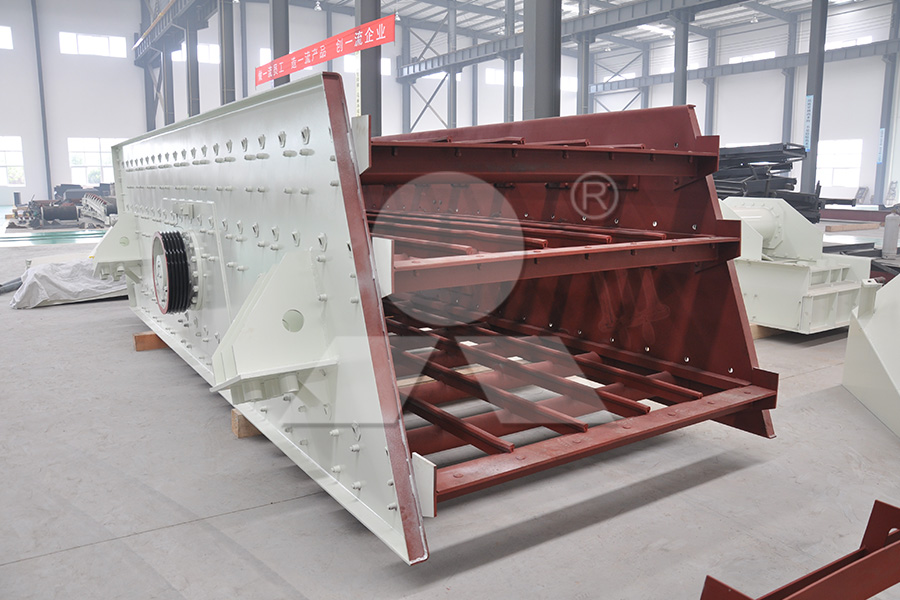

Liming jaw crusher shows the power of primary crushing with its powerful crushing force! Deep V crushing chamber, no blockage even if it takes a lot of materials; integral motor bracket, more convenient transportation and installation; wedge block to adjust the discharge port, the discharge particle size can be easily adjusted in 3 minutes; the hourly output can reach 1500 tons, high production capacity and low failure!

2. Gyratory crusher - the first choice for large-scale mining projects

Liming HCG series gyratory crusher is a new type of coarse crushing equipment with large production capacity, high efficiency and intelligence manufactured by Liming Group using advanced technology! The third-generation spindle control system has more stable particle shape; increased crushing chamber inclination and lengthened crushing surface have higher efficiency; patented crushing chamber design has more uniform wear and lower production cost. European standard reinforced heavy-duty spindle design, ultra-high strength, worry-free harsh working conditions. Suitable for crushing of limestone, basalt, granite and other materials of different hardness. Large processing capacity, suitable for continuous operation in large mines.

3. Heavy hammer crusher - the king of cost-effectiveness for small and medium-sized projects

Liming heavy hammer crusher is widely used in many fields such as mining, smelting, building materials, transportation, water conservancy, etc.; one-time breaking, two-time breaking, one-time forming, it can reduce the cost of the same level of products by about 40%; no grate design, dry and wet crushing, adjustable discharging, no jamming, no clogging, it has better performance than the same level of products, and simplifies the secondary crushing process.

Choosing the right rough crushing equipment is the first step for efficient production in mines. Liming Machinery has been deeply involved in the field of mining machinery for 40 years, building a full-cycle service system of "pre-sales-sales-after-sales", from the scheme design in the equipment selection stage, to the on-site guidance in the installation and commissioning stage, to the direct supply of original parts in the operation period, providing 7×24 hours of technical consultation and fault reporting channels, reducing the user's operation and maintenance costs throughout the process.

Liming Machinery has become a long-term partner of global customers with its rich technical experience, reliable equipment performance and perfect after-sales service. If you need a customized rough crushing solution, welcome to Liming Machinery for an on-site inspection and visit, we will provide you with professional support!

Previous: SMP Crusher

Next: SMP Crusher

In the fields of mining, sand and gravel aggregate production, etc., coarse crushing equipment, as the "first checkpoint" of the crushing production line, undertakes the key task of initially crushing large pieces of raw stone into smaller pa

In the fields of mining, sand and gravel aggregate production, etc., coarse crushing equipment, as the "first checkpoint" of the crushing production line, undertakes the key task of initially crushing large pieces of raw stone into smaller particles. Choosing an efficient and durable coarse crushing equipment can not only improve the overall production efficiency, but also reduce operating costs.

1. The important role of coarse crushing equipment in the field of mining machinery crushing

1. Rapid processing of large pieces of raw materials: Coarse crushing equipment can quickly crush the mined raw ore (such as granite, limestone, etc.) to a particle size suitable for medium and fine crushing, laying the foundation for subsequent processes.

2. Reduce energy consumption and cost: Pre-reducing the volume of materials through the coarse crushing link can greatly reduce the load of medium and fine crushing equipment, extend the life of the equipment, and save energy.

3. Ensure the continuity of the production line: Stable coarse crushing capacity is the core of the efficient operation of the production line, avoiding the shutdown of the entire line due to equipment failure.

2. How to choose a suitable coarse crushing equipment? Three tricks to get it done!

The first step: clarify material characteristics and production requirements

Material hardness and composition: high-hardness ores (such as granite) require equipment with high compressive strength (such as jaw crushers); sticky materials require anti-blocking design.

Capacity requirements: select matching models according to the hourly processing volume (such as 100-1500 tons) to avoid "big horses pulling small carts" or overload operation.

Discharge particle size requirements: the size of the material after coarse crushing needs to be adapted to the subsequent process (such as secondary crushing or direct screening).

The second step: pay attention to equipment performance and energy consumption

Crushing ratio: high crushing ratio equipment can reduce the number of crushing stages and save investment costs.

Wear resistance and maintenance convenience: key components (such as jaw plates and rotors) are made of high-strength alloy materials, and the structural design is easy to repair.

Energy consumption and environmental protection: choose energy-saving motors and low-noise designs to meet the trend of green production.

The third step: examine brand technology and service guarantee

Give priority to brands with mature technology and good reputation to ensure equipment operation stability and after-sales support capabilities.

3. Common coarse crushing equipment types

Jaw crusher - the first choice for coarse crushing of medium and high hardness materials

Liming jaw crusher shows the power of primary crushing with its powerful crushing force! Deep V crushing chamber, no blockage even if it takes a lot of materials; integral motor bracket, more convenient transportation and installation; wedge block to adjust the discharge port, the discharge particle size can be easily adjusted in 3 minutes; the hourly output can reach 1500 tons, high production capacity and low failure!

2. Gyratory crusher - the first choice for large-scale mining projects

Liming HCG series gyratory crusher is a new type of coarse crushing equipment with large production capacity, high efficiency and intelligence manufactured by Liming Group using advanced technology! The third-generation spindle control system has more stable particle shape; increased crushing chamber inclination and lengthened crushing surface have higher efficiency; patented crushing chamber design has more uniform wear and lower production cost. European standard reinforced heavy-duty spindle design, ultra-high strength, worry-free harsh working conditions. Suitable for crushing of limestone, basalt, granite and other materials of different hardness. Large processing capacity, suitable for continuous operation in large mines.

3. Heavy hammer crusher - the king of cost-effectiveness for small and medium-sized projects

Liming heavy hammer crusher is widely used in many fields such as mining, smelting, building materials, transportation, water conservancy, etc.; one-time breaking, two-time breaking, one-time forming, it can reduce the cost of the same level of products by about 40%; no grate design, dry and wet crushing, adjustable discharging, no jamming, no clogging, it has better performance than the same level of products, and simplifies the secondary crushing process.

Choosing the right rough crushing equipment is the first step for efficient production in mines. Liming Machinery has been deeply involved in the field of mining machinery for 40 years, building a full-cycle service system of "pre-sales-sales-after-sales", from the scheme design in the equipment selection stage, to the on-site guidance in the installation and commissioning stage, to the direct supply of original parts in the operation period, providing 7×24 hours of technical consultation and fault reporting channels, reducing the user's operation and maintenance costs throughout the process.

Liming Machinery has become a long-term partner of global customers with its rich technical experience, reliable equipment performance and perfect after-sales service. If you need a customized rough crushing solution, welcome to Liming Machinery for an on-site inspection and visit, we will provide you with professional support!

Previous: SMP Crusher

Next: SMP Crusher

The material is hard and uneven in particle size? Liming double roll crusher can easily solve the problem of sand and gravel aggregates

The material is hard and uneven in particle size? Liming double roll crusher can easily solve the problem of sand and gravel aggregates Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly

Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost

Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution

The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future

The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future The material is hard and uneven in particle size? Liming double roll crusher can easily solve the problem of sand and gravel aggregates

The material is hard and uneven in particle size? Liming double roll crusher can easily solve the problem of sand and gravel aggregates Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly

Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost

Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution

The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future

The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future