In the construction of roads and bridges, the selection of building materials such as sand and gravel aggregates, asphalt concrete, and concrete is critical and affects cost and quality. Equipment such as C6X crusher, HPT cone crusher, and VU aggregate

In the construction of roads and bridges, the selection of building materials such as sand and gravel aggregates, asphalt concrete, and concrete is critical and affects cost and quality. Equipment such as C6X crusher, HPT cone crusher, and VU aggregate optimization system ensure high-quality materials. Understand building materials and equipment to ensure project quality and safety and promote sustainable development.

In the construction of roads and bridges, the selection of various building materials is crucial. They not only affect the cost and construction period of the project, but are also directly related to the quality and service life of the project. Therefore, it is particularly important to understand the commonly used construction materials and their corresponding production equipment.

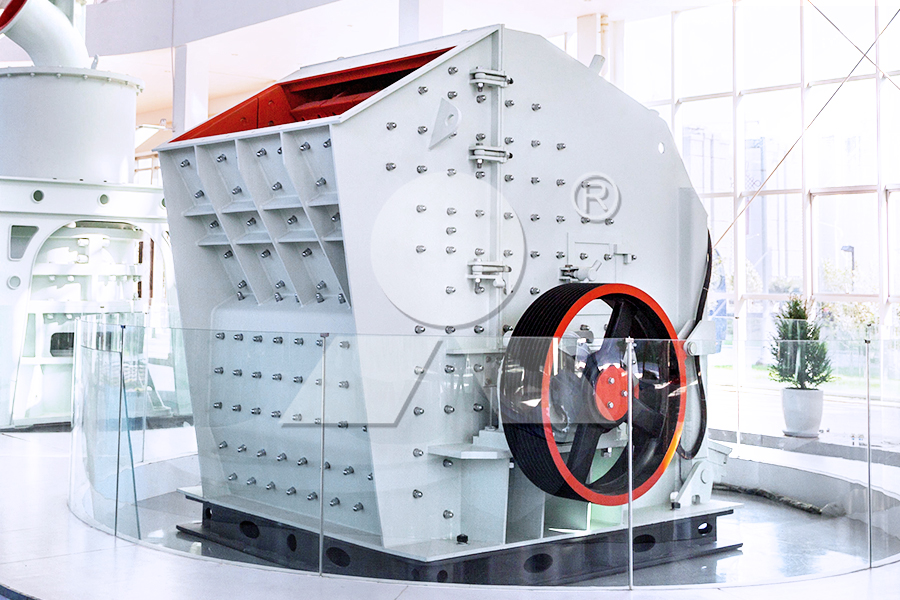

Introduction to sand and gravel aggregate equipment for roads and bridges

Main construction materials

Sand and gravel aggregate

Sand and gravel aggregates are the most used materials in road and bridge projects. They are divided into coarse aggregates and fine aggregates. The former is used for masonry structures, while the latter is a key component of concrete and asphalt mixtures. Suitable equipment, such as the C6X series jaw crusher, can effectively process ores with a compressive strength of no more than 300MPa, ensuring the production of high-quality sand and gravel aggregates.

Asphalt concrete

Asphalt is mainly used for paving roads, and its ingredients include crushed stone and mineral powder. HPT hydraulic cone crusher can ensure uniform mixing and improve the durability and stability of roads.

Concrete

Concrete, a mixture of cement, sand, gravel and other materials, is the foundation of modern construction. Using VU aggregate optimization system can ensure the mix ratio and strength of concrete, thereby improving the quality of construction.

Common types of sand and gravel aggregates

Natural sand: naturally formed, widely used in concrete.

Washed river sand: After washing, impurities are removed, suitable for high-standard projects.

Machine-made sand: made of rocks and mine waste, with excellent particle shape, suitable for concrete preparation.

Melon seeds, dog head stones, etc.: building aggregates with their own characteristics, suitable for different engineering needs.

Characteristics and selection of sand and gravel aggregates

The role of different types of sand and gravel aggregates in construction cannot be underestimated. The reasonable combination of fine aggregate and coarse aggregate can ensure the strength and stability of concrete. For example, yellow sand is fine and suitable for concrete preparation, while crushed stone is widely used in road construction because of its hard and wear-resistant properties.

The key to equipment selection

When choosing sand and gravel aggregate production equipment, it should be reasonably matched according to project requirements and material characteristics. Different types of crushers and sand making machines can effectively improve production efficiency and material quality, ensuring the safety and durability of road and bridge projects.

In summary, understanding road and bridge construction materials and their corresponding production equipment is the basis for ensuring project quality and safety. Choosing appropriate materials and equipment will surely lay a solid foundation for the sustainable development of modern construction.

Previous: SMP Crusher

Next: SMP Crusher

In the construction of roads and bridges, the selection of building materials such as sand and gravel aggregates, asphalt concrete, and concrete is critical and affects cost and quality. Equipment such as C6X crusher, HPT cone crusher, and VU aggregate

In the construction of roads and bridges, the selection of building materials such as sand and gravel aggregates, asphalt concrete, and concrete is critical and affects cost and quality. Equipment such as C6X crusher, HPT cone crusher, and VU aggregate optimization system ensure high-quality materials. Understand building materials and equipment to ensure project quality and safety and promote sustainable development.

In the construction of roads and bridges, the selection of various building materials is crucial. They not only affect the cost and construction period of the project, but are also directly related to the quality and service life of the project. Therefore, it is particularly important to understand the commonly used construction materials and their corresponding production equipment.

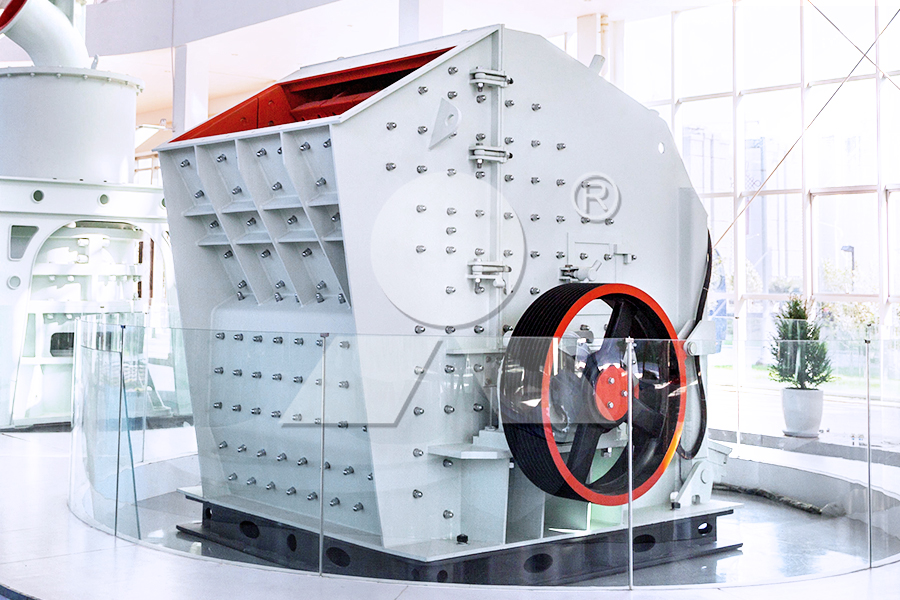

Introduction to sand and gravel aggregate equipment for roads and bridges

Main construction materials

Sand and gravel aggregate

Sand and gravel aggregates are the most used materials in road and bridge projects. They are divided into coarse aggregates and fine aggregates. The former is used for masonry structures, while the latter is a key component of concrete and asphalt mixtures. Suitable equipment, such as the C6X series jaw crusher, can effectively process ores with a compressive strength of no more than 300MPa, ensuring the production of high-quality sand and gravel aggregates.

Asphalt concrete

Asphalt is mainly used for paving roads, and its ingredients include crushed stone and mineral powder. HPT hydraulic cone crusher can ensure uniform mixing and improve the durability and stability of roads.

Concrete

Concrete, a mixture of cement, sand, gravel and other materials, is the foundation of modern construction. Using VU aggregate optimization system can ensure the mix ratio and strength of concrete, thereby improving the quality of construction.

Common types of sand and gravel aggregates

Natural sand: naturally formed, widely used in concrete.

Washed river sand: After washing, impurities are removed, suitable for high-standard projects.

Machine-made sand: made of rocks and mine waste, with excellent particle shape, suitable for concrete preparation.

Melon seeds, dog head stones, etc.: building aggregates with their own characteristics, suitable for different engineering needs.

Characteristics and selection of sand and gravel aggregates

The role of different types of sand and gravel aggregates in construction cannot be underestimated. The reasonable combination of fine aggregate and coarse aggregate can ensure the strength and stability of concrete. For example, yellow sand is fine and suitable for concrete preparation, while crushed stone is widely used in road construction because of its hard and wear-resistant properties.

The key to equipment selection

When choosing sand and gravel aggregate production equipment, it should be reasonably matched according to project requirements and material characteristics. Different types of crushers and sand making machines can effectively improve production efficiency and material quality, ensuring the safety and durability of road and bridge projects.

In summary, understanding road and bridge construction materials and their corresponding production equipment is the basis for ensuring project quality and safety. Choosing appropriate materials and equipment will surely lay a solid foundation for the sustainable development of modern construction.

Previous: SMP Crusher

Next: SMP Crusher

1000 tons per hour crushing sand making production line

1000 tons per hour crushing sand making production line Analysis by sand and gravel equipment manufacturers: How much does a 500 ton/hour crushing production line cost?

Analysis by sand and gravel equipment manufacturers: How much does a 500 ton/hour crushing production line cost? Shandong 2000t/h concrete mixing station sand and gravel aggregate production line

Shandong 2000t/h concrete mixing station sand and gravel aggregate production line Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project

Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project What are the advantages of mobile iron ore crusher? How much does it cost?

What are the advantages of mobile iron ore crusher? How much does it cost? 1000 tons per hour crushing sand making production line

1000 tons per hour crushing sand making production line Analysis by sand and gravel equipment manufacturers: How much does a 500 ton/hour crushing production line cost?

Analysis by sand and gravel equipment manufacturers: How much does a 500 ton/hour crushing production line cost? Shandong 2000t/h concrete mixing station sand and gravel aggregate production line

Shandong 2000t/h concrete mixing station sand and gravel aggregate production line Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project

Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project What are the advantages of mobile iron ore crusher? How much does it cost?

What are the advantages of mobile iron ore crusher? How much does it cost?