In the mining industry, hematite, as an important type of iron ore, requires particularly important mining and processing procedures. This article will provide an in-depth analysis of the entire hematite mining and crushing process, as well as the comp

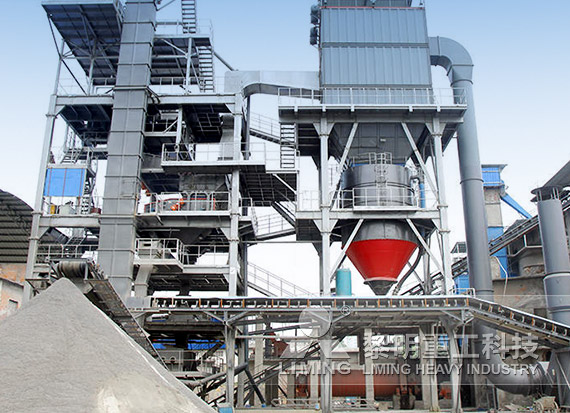

In the mining industry, hematite, as an important type of iron ore, requires particularly important mining and processing procedures. This article will provide an in-depth analysis of the entire hematite mining and crushing process, as well as the complete set of processing equipment required.

More magnetite crushing equipment

I. Overview of Hematite Mining and Crushing

Hematite mining begins with blasting on the mountain, followed by a series of fine crushing and screening processes to transform the raw ore into finished products that meet the requirements. In this process, selecting appropriate processing equipment and a reasonable production line configuration is crucial for improving crushing efficiency and reducing costs.

II. Detailed Explanation of the Complete Set of Processing Equipment

1. Dump Truck and Vibrating Feeder: Dump trucks transport the hematite ore, smaller than 1020mm after blasting, to the vibrating feeder. The vibrating feeder, with its uniform and continuous feeding method, ensures the stable operation of subsequent crushing equipment.

2. PE1200x1500 Deep Cavity Jaw Crusher: As the primary crushing equipment, the jaw crusher, with its powerful crushing force and high crushing efficiency, crushes the ore to a particle size of approximately 150mm-300mm.

3. HPT400 Hydraulic Cone Crusher: The ore initially crushed by the jaw crusher enters the hydraulic cone crusher for secondary crushing. This equipment uses advanced hydraulic technology and can easily handle the crushing needs of high-hardness ores.

4. 5X1145 Sand Making and Shaping Machine: The crushed ore enters the sand making and shaping machine for shaping treatment to ensure that the finished ore has a uniform particle size and regular shape.

5. Circular Vibrating Screen and Belt Conveyor: The circular vibrating screen is responsible for screening the crushed ore, separating the qualified finished products from the unqualified ones. The belt conveyor then transports the finished products and unqualified products to designated areas.

6. Electrical Control Equipment: The entire production line is equipped with an advanced electrical control system to achieve automated control and fault warning, ensuring the stable operation of the production line.

III. Production Line Advantages Analysis

This production line, while fully considering the hardness of hematite, achieves efficient and low-cost crushing and processing through reasonable equipment configuration and production line layout. At the same time, the production line boasts a high level of automation and intelligence, reducing the difficulty of manual operation and safety hazards, and improving production efficiency and product quality.

In short, the mining and crushing of hematite is a complex and meticulous process. By selecting appropriate processing equipment and a rational production line configuration, efficient and low-cost processing of hematite can be achieved, providing strong support for the development of the mining industry.

Previous: SMP Crusher

Next: SMP Crusher

In the mining industry, hematite, as an important type of iron ore, requires particularly important mining and processing procedures. This article will provide an in-depth analysis of the entire hematite mining and crushing process, as well as the comp

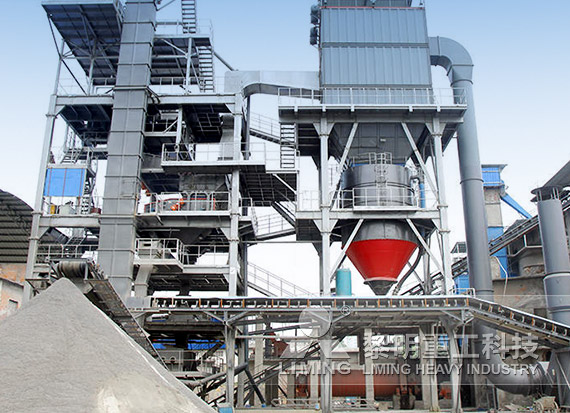

In the mining industry, hematite, as an important type of iron ore, requires particularly important mining and processing procedures. This article will provide an in-depth analysis of the entire hematite mining and crushing process, as well as the complete set of processing equipment required.

More magnetite crushing equipment

I. Overview of Hematite Mining and Crushing

Hematite mining begins with blasting on the mountain, followed by a series of fine crushing and screening processes to transform the raw ore into finished products that meet the requirements. In this process, selecting appropriate processing equipment and a reasonable production line configuration is crucial for improving crushing efficiency and reducing costs.

II. Detailed Explanation of the Complete Set of Processing Equipment

1. Dump Truck and Vibrating Feeder: Dump trucks transport the hematite ore, smaller than 1020mm after blasting, to the vibrating feeder. The vibrating feeder, with its uniform and continuous feeding method, ensures the stable operation of subsequent crushing equipment.

2. PE1200x1500 Deep Cavity Jaw Crusher: As the primary crushing equipment, the jaw crusher, with its powerful crushing force and high crushing efficiency, crushes the ore to a particle size of approximately 150mm-300mm.

3. HPT400 Hydraulic Cone Crusher: The ore initially crushed by the jaw crusher enters the hydraulic cone crusher for secondary crushing. This equipment uses advanced hydraulic technology and can easily handle the crushing needs of high-hardness ores.

4. 5X1145 Sand Making and Shaping Machine: The crushed ore enters the sand making and shaping machine for shaping treatment to ensure that the finished ore has a uniform particle size and regular shape.

5. Circular Vibrating Screen and Belt Conveyor: The circular vibrating screen is responsible for screening the crushed ore, separating the qualified finished products from the unqualified ones. The belt conveyor then transports the finished products and unqualified products to designated areas.

6. Electrical Control Equipment: The entire production line is equipped with an advanced electrical control system to achieve automated control and fault warning, ensuring the stable operation of the production line.

III. Production Line Advantages Analysis

This production line, while fully considering the hardness of hematite, achieves efficient and low-cost crushing and processing through reasonable equipment configuration and production line layout. At the same time, the production line boasts a high level of automation and intelligence, reducing the difficulty of manual operation and safety hazards, and improving production efficiency and product quality.

In short, the mining and crushing of hematite is a complex and meticulous process. By selecting appropriate processing equipment and a rational production line configuration, efficient and low-cost processing of hematite can be achieved, providing strong support for the development of the mining industry.

Previous: SMP Crusher

Next: SMP Crusher

How to choose the right model of large-scale mining crusher?

How to choose the right model of large-scale mining crusher? Complete set of equipment for stone crushing production line

Complete set of equipment for stone crushing production line A new powerful tool for energy saving and consumption reduction: The application of HPT multi-cylinder hydraulic cone crushers in metal mines.

A new powerful tool for energy saving and consumption reduction: The application of HPT multi-cylinder hydraulic cone crushers in metal mines. The powerful HST single-cylinder hydraulic cone crusher for hard rock crushing: an intelligent and efficient modern crushing equipment.

The powerful HST single-cylinder hydraulic cone crusher for hard rock crushing: an intelligent and efficient modern crushing equipment. How is granite processed into manufactured sand?

How is granite processed into manufactured sand? How to choose the right model of large-scale mining crusher?

How to choose the right model of large-scale mining crusher? Complete set of equipment for stone crushing production line

Complete set of equipment for stone crushing production line A new powerful tool for energy saving and consumption reduction: The application of HPT multi-cylinder hydraulic cone crushers in metal mines.

A new powerful tool for energy saving and consumption reduction: The application of HPT multi-cylinder hydraulic cone crushers in metal mines. The powerful HST single-cylinder hydraulic cone crusher for hard rock crushing: an intelligent and efficient modern crushing equipment.

The powerful HST single-cylinder hydraulic cone crusher for hard rock crushing: an intelligent and efficient modern crushing equipment. How is granite processed into manufactured sand?

How is granite processed into manufactured sand?