In asphalt concrete pavement engineering, the processing quality of raw materials directly affects the overall quality and cost of the project. Material costs are a major component of pavement engineering costs; therefore, effectively saving on materia

In asphalt concrete pavement engineering, the processing quality of raw materials directly affects the overall quality and cost of the project. Material costs are a major component of pavement engineering costs; therefore, effectively saving on material costs while ensuring raw material quality is a key aspect of project cost control.

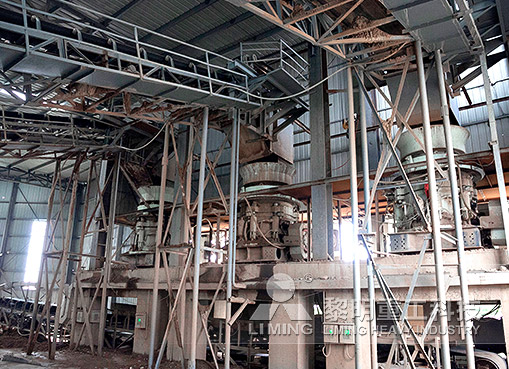

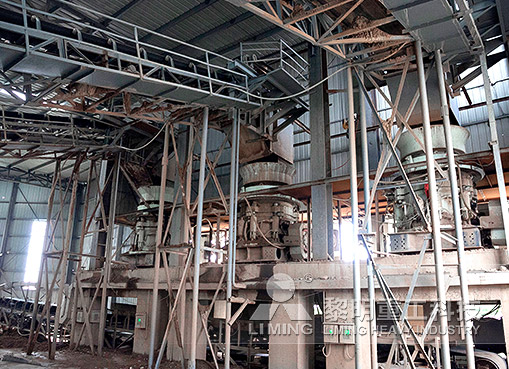

Asphalt Pavement Aggregate Processing Equipment

Asphalt Pavement Aggregate Processing Equipment

The Importance of Raw Material Quality

High-quality raw materials are the foundation for ensuring the quality of asphalt pavement construction. Stable raw material quality reduces fluctuations in the mixing plant's production process, improves production efficiency, avoids problems such as material shortages and spills, and ensures smooth construction.

Processing Technology and Requirements

Process Flow

Raw material processing utilizes advanced equipment such as vibrating feeders, jaw crushers, cone crushers, and impact crushers. Through multi-stage crushing and screening, finished aggregates that meet specifications are obtained. Especially for hard rocks such as basalt, shaping machines are required to optimize particle shape.

Processing Requirements

On-site Inspection: During processing, dedicated personnel must be responsible for inspection and timely removal of non-compliant ores and debris.

Equipment Configuration: At least a two-stage or higher combined crushing system should be used, equipped with a strip-type baffle screen to filter out mud and impurities.

Screening and Dust Control: Multiple spare vibrating screens should be available, and dust collection devices should be installed to strictly control dust content.

Regular Inspection: Regularly inspect and maintain equipment such as crushers, vibrating screens, and dust collectors to ensure stable operation.

Quality Control Key Points:

Screen Specifications: Set reasonable screen aperture sizes according to road surface layer requirements to ensure accurate aggregate specifications.

Dust Control Measures: Strengthen dust collection efforts by using bag filters and installing filter screens to reduce dust content.

Mud and Soft Stone Control: Reduce the mixing of mud and soft stone through site cleaning, hardening treatment, and strict material selection.

Needle-shaped and Flaky Particle Content Control: Use high-quality crusher jaws, maintain a stable and continuous feed, and adjust the optimal discharge opening ratio to reduce needle-shaped and flaky particles.

Environmental Awareness: Strengthen site hardening and drainage treatment, and adopt environmentally friendly equipment and technologies to reduce the environmental impact of construction.

In conclusion, by strictly controlling every step of the raw material processing to ensure stable raw material quality, we can not only effectively improve the construction quality of asphalt pavement, but also reasonably control material costs while ensuring quality, thus optimizing project costs. At the same time, strengthening environmental awareness and adopting effective environmental protection measures is also an indispensable and crucial part of modern pavement construction.

Previous: SMP Crusher

Next: SMP Crusher

In asphalt concrete pavement engineering, the processing quality of raw materials directly affects the overall quality and cost of the project. Material costs are a major component of pavement engineering costs; therefore, effectively saving on materia

In asphalt concrete pavement engineering, the processing quality of raw materials directly affects the overall quality and cost of the project. Material costs are a major component of pavement engineering costs; therefore, effectively saving on material costs while ensuring raw material quality is a key aspect of project cost control.

Asphalt Pavement Aggregate Processing Equipment

Asphalt Pavement Aggregate Processing Equipment

The Importance of Raw Material Quality

High-quality raw materials are the foundation for ensuring the quality of asphalt pavement construction. Stable raw material quality reduces fluctuations in the mixing plant's production process, improves production efficiency, avoids problems such as material shortages and spills, and ensures smooth construction.

Processing Technology and Requirements

Process Flow

Raw material processing utilizes advanced equipment such as vibrating feeders, jaw crushers, cone crushers, and impact crushers. Through multi-stage crushing and screening, finished aggregates that meet specifications are obtained. Especially for hard rocks such as basalt, shaping machines are required to optimize particle shape.

Processing Requirements

On-site Inspection: During processing, dedicated personnel must be responsible for inspection and timely removal of non-compliant ores and debris.

Equipment Configuration: At least a two-stage or higher combined crushing system should be used, equipped with a strip-type baffle screen to filter out mud and impurities.

Screening and Dust Control: Multiple spare vibrating screens should be available, and dust collection devices should be installed to strictly control dust content.

Regular Inspection: Regularly inspect and maintain equipment such as crushers, vibrating screens, and dust collectors to ensure stable operation.

Quality Control Key Points:

Screen Specifications: Set reasonable screen aperture sizes according to road surface layer requirements to ensure accurate aggregate specifications.

Dust Control Measures: Strengthen dust collection efforts by using bag filters and installing filter screens to reduce dust content.

Mud and Soft Stone Control: Reduce the mixing of mud and soft stone through site cleaning, hardening treatment, and strict material selection.

Needle-shaped and Flaky Particle Content Control: Use high-quality crusher jaws, maintain a stable and continuous feed, and adjust the optimal discharge opening ratio to reduce needle-shaped and flaky particles.

Environmental Awareness: Strengthen site hardening and drainage treatment, and adopt environmentally friendly equipment and technologies to reduce the environmental impact of construction.

In conclusion, by strictly controlling every step of the raw material processing to ensure stable raw material quality, we can not only effectively improve the construction quality of asphalt pavement, but also reasonably control material costs while ensuring quality, thus optimizing project costs. At the same time, strengthening environmental awareness and adopting effective environmental protection measures is also an indispensable and crucial part of modern pavement construction.

Previous: SMP Crusher

Next: SMP Crusher

Improving mining efficiency: Key aspects of cone crusher motor cone liner maintenance

Improving mining efficiency: Key aspects of cone crusher motor cone liner maintenance What types of large crushers are available? How much do they cost?

What types of large crushers are available? How much do they cost? Shibang participated in the technological upgrading of a 70-ton-per-hour dry sand making project in Ningbo, Zhejiang.

Shibang participated in the technological upgrading of a 70-ton-per-hour dry sand making project in Ningbo, Zhejiang. How much does a mobile crushing machine cost?

How much does a mobile crushing machine cost? Zhejiang 3.4 million-ton-per-year high-quality basalt sand and gravel aggregate production line

Zhejiang 3.4 million-ton-per-year high-quality basalt sand and gravel aggregate production line Improving mining efficiency: Key aspects of cone crusher motor cone liner maintenance

Improving mining efficiency: Key aspects of cone crusher motor cone liner maintenance What types of large crushers are available? How much do they cost?

What types of large crushers are available? How much do they cost? Shibang participated in the technological upgrading of a 70-ton-per-hour dry sand making project in Ningbo, Zhejiang.

Shibang participated in the technological upgrading of a 70-ton-per-hour dry sand making project in Ningbo, Zhejiang. How much does a mobile crushing machine cost?

How much does a mobile crushing machine cost? Zhejiang 3.4 million-ton-per-year high-quality basalt sand and gravel aggregate production line

Zhejiang 3.4 million-ton-per-year high-quality basalt sand and gravel aggregate production line