Jiangxi Building Materials Enterprise invested in a 600,000-ton limestone tailings resource utilization project. The project uses the advanced VU120 aggregate optimization system to provide the local construction market with high-quality machine-made s

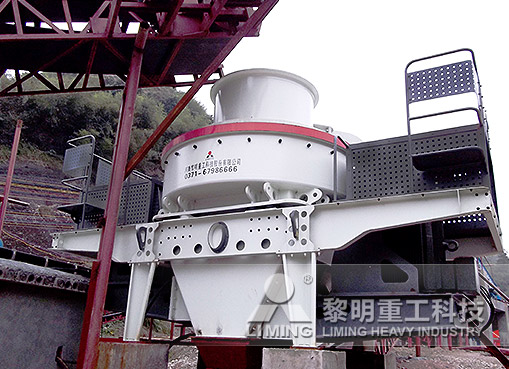

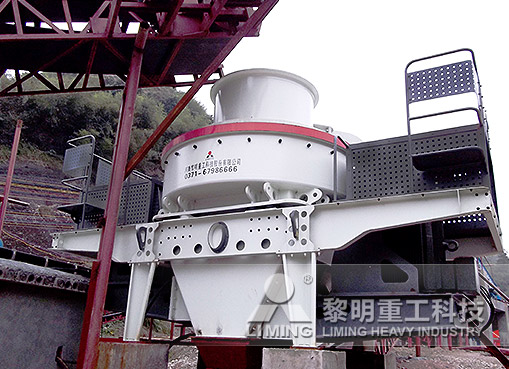

Jiangxi Building Materials Enterprise invested in a 600,000-ton limestone tailings resource utilization project. The project uses the advanced VU120 aggregate optimization system to provide the local construction market with high-quality machine-made sand products that meet national standards.

Project Overview

Raw material characteristics: limestone, tailings and melon stone with a particle size of 0-16mm

Design capacity: 100-120 tons per hour

Finished product application: mainly used in cement production and advanced concrete preparation

Core technology and process

Innovative advantages of VU aggregate optimization system Liming relies on a professional technical team to solve technical problems such as particle shape control and environmental dust removal in machine-made sand production. The system has the following significant features:

(1) Particle shape optimization technology:

Using waterfall self-grinding brush process

Low-energy crushing and shaping

Reduced porosity of finished sand

(2) Intelligent control system:

Adjustable range of fineness modulus

Powder content can be adjusted according to demand

Stable moisture content control

Environmentally friendly design: The project adopts a fully enclosed production process, equipped with a negative pressure dust removal system and an automatic humidification device to achieve dust concentration in the production process below the national standard limit.

Project implementation effect

Product quality:

The finished sand particles are round and reasonably graded, which can fully meet the preparation requirements of high-grade concrete.

Resource utilization efficiency:

Through the optimization process, efficient utilization of tailings resources is achieved, and the comprehensive utilization rate of raw materials exceeds 95%.

Environmental benefits:

Compared with the traditional wet process, it has obvious water-saving effect, no wastewater discharge problem, and high dust collection rate.

The successful implementation of this project has provided a feasible solution to the problem of shortage of natural sand resources. Its environmental protection concept and technological innovation have a positive role in promoting the transformation and upgrading of the building materials industry.

Previous: SMP Crusher

Next: SMP Crusher

Jiangxi Building Materials Enterprise invested in a 600,000-ton limestone tailings resource utilization project. The project uses the advanced VU120 aggregate optimization system to provide the local construction market with high-quality machine-made s

Jiangxi Building Materials Enterprise invested in a 600,000-ton limestone tailings resource utilization project. The project uses the advanced VU120 aggregate optimization system to provide the local construction market with high-quality machine-made sand products that meet national standards.

Project Overview

Raw material characteristics: limestone, tailings and melon stone with a particle size of 0-16mm

Design capacity: 100-120 tons per hour

Finished product application: mainly used in cement production and advanced concrete preparation

Core technology and process

Innovative advantages of VU aggregate optimization system Liming relies on a professional technical team to solve technical problems such as particle shape control and environmental dust removal in machine-made sand production. The system has the following significant features:

(1) Particle shape optimization technology:

Using waterfall self-grinding brush process

Low-energy crushing and shaping

Reduced porosity of finished sand

(2) Intelligent control system:

Adjustable range of fineness modulus

Powder content can be adjusted according to demand

Stable moisture content control

Environmentally friendly design: The project adopts a fully enclosed production process, equipped with a negative pressure dust removal system and an automatic humidification device to achieve dust concentration in the production process below the national standard limit.

Project implementation effect

Product quality:

The finished sand particles are round and reasonably graded, which can fully meet the preparation requirements of high-grade concrete.

Resource utilization efficiency:

Through the optimization process, efficient utilization of tailings resources is achieved, and the comprehensive utilization rate of raw materials exceeds 95%.

Environmental benefits:

Compared with the traditional wet process, it has obvious water-saving effect, no wastewater discharge problem, and high dust collection rate.

The successful implementation of this project has provided a feasible solution to the problem of shortage of natural sand resources. Its environmental protection concept and technological innovation have a positive role in promoting the transformation and upgrading of the building materials industry.

Previous: SMP Crusher

Next: SMP Crusher

What machine is used to crush pebbles

What machine is used to crush pebbles Stone crusher complete equipment

Stone crusher complete equipment Liming large-scale mining crushing production line overall solution

Liming large-scale mining crushing production line overall solution Advantages of cone crusher production line in stone crushing operation

Advantages of cone crusher production line in stone crushing operation Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection

Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection What machine is used to crush pebbles

What machine is used to crush pebbles Stone crusher complete equipment

Stone crusher complete equipment Liming large-scale mining crushing production line overall solution

Liming large-scale mining crushing production line overall solution Advantages of cone crusher production line in stone crushing operation

Advantages of cone crusher production line in stone crushing operation Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection

Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection