1. Project Introduction1.1 Raw Material Processing CapacityThe project is equipped with a complete production line system for processing river pebbles and limestone, with a raw material processing capacity of 500 tons/hour, and can stably

1. Project Introduction

1.1 Raw Material Processing Capacity

The project is equipped with a complete production line system for processing river pebbles and limestone, with a raw material processing capacity of 500 tons/hour, and can stably produce various specifications of sand and gravel aggregates for construction.

1.2 Product indicators

The production line can produce high-quality machine-made sand of 0-5mm, and the products meet the national standards for construction sand, meeting the needs of various construction projects.

1.3 Process characteristics

Adopting advanced wet processing technology, equipped with a complete dust removal and sewage treatment system, it realizes efficient resource utilization and environmentally friendly clean production.

Liming Group

Crushing/Sand Making/Grinding Consultation

Call Now

2. Key Technical Features

2.1 Intelligent Control System

The production line adopts a PLC automatic control system to realize one-button start and stop, fault alarm, operation monitoring and other functions, which improves production efficiency and safety.

2.2 High-efficiency crushing process

The process flow of two-stage crushing + sand making is adopted:

The jaw crusher with large feed inlet is used for coarse crushing

The hydraulic cone crusher is configured for medium and fine crushing

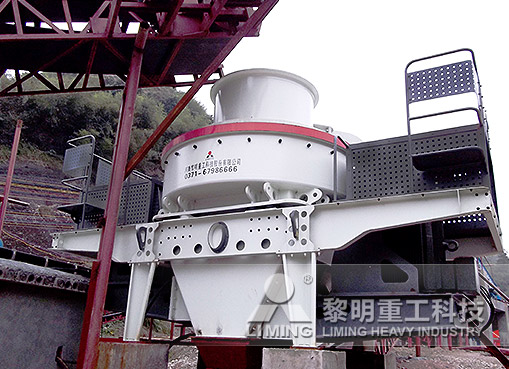

The vertical shaft impact crusher is used for shaping sand making

2.3 Environmental protection treatment system

Equipped with:

Pulse dust removal device

Circulating water treatment system

Noise-proof and sound-proof facilities

III. Core equipment configuration

3.1 Crushing equipment

C6X jaw crusher: large crushing ratio, high efficiency

HPT multi-cylinder hydraulic cone crusher: high output, low energy consumption

HST single-cylinder hydraulic cone crusher: stable product particle size

3.2 Auxiliary equipment

VSI6X sand making machine: excellent finished sand particle shape

F5X vibrating feeder: uniform and continuous feeding

S5X vibrating screen: efficient and accurate classification

IV. Project advantages

4.1 Technological advancement

The equipment adopts advanced technologies such as hydraulic adjustment and intelligent control to ensure stable and reliable operation of the production line. The system configuration is reasonable and the processing capacity is strong.

4.2 Economical and practical

Compact overall layout, saving land

Equipment maintenance is simple, low cost of use

4.3 Environmental protection and energy saving

Less dust emission during the production process

High water recycling rate

Excellent equipment energy consumption index

4.4 Product advantages

The finished machine-made sand has good grain shape, reasonable grading and stable quality, which fully meets the requirements of high-grade concrete production.

Previous: SMP Crusher

Next: SMP Crusher

1. Project Introduction1.1 Raw Material Processing CapacityThe project is equipped with a complete production line system for processing river pebbles and limestone, with a raw material processing capacity of 500 tons/hour, and can stably

1. Project Introduction

1.1 Raw Material Processing Capacity

The project is equipped with a complete production line system for processing river pebbles and limestone, with a raw material processing capacity of 500 tons/hour, and can stably produce various specifications of sand and gravel aggregates for construction.

1.2 Product indicators

The production line can produce high-quality machine-made sand of 0-5mm, and the products meet the national standards for construction sand, meeting the needs of various construction projects.

1.3 Process characteristics

Adopting advanced wet processing technology, equipped with a complete dust removal and sewage treatment system, it realizes efficient resource utilization and environmentally friendly clean production.

Liming Group

Crushing/Sand Making/Grinding Consultation

Call Now

2. Key Technical Features

2.1 Intelligent Control System

The production line adopts a PLC automatic control system to realize one-button start and stop, fault alarm, operation monitoring and other functions, which improves production efficiency and safety.

2.2 High-efficiency crushing process

The process flow of two-stage crushing + sand making is adopted:

The jaw crusher with large feed inlet is used for coarse crushing

The hydraulic cone crusher is configured for medium and fine crushing

The vertical shaft impact crusher is used for shaping sand making

2.3 Environmental protection treatment system

Equipped with:

Pulse dust removal device

Circulating water treatment system

Noise-proof and sound-proof facilities

III. Core equipment configuration

3.1 Crushing equipment

C6X jaw crusher: large crushing ratio, high efficiency

HPT multi-cylinder hydraulic cone crusher: high output, low energy consumption

HST single-cylinder hydraulic cone crusher: stable product particle size

3.2 Auxiliary equipment

VSI6X sand making machine: excellent finished sand particle shape

F5X vibrating feeder: uniform and continuous feeding

S5X vibrating screen: efficient and accurate classification

IV. Project advantages

4.1 Technological advancement

The equipment adopts advanced technologies such as hydraulic adjustment and intelligent control to ensure stable and reliable operation of the production line. The system configuration is reasonable and the processing capacity is strong.

4.2 Economical and practical

Compact overall layout, saving land

Equipment maintenance is simple, low cost of use

4.3 Environmental protection and energy saving

Less dust emission during the production process

High water recycling rate

Excellent equipment energy consumption index

4.4 Product advantages

The finished machine-made sand has good grain shape, reasonable grading and stable quality, which fully meets the requirements of high-grade concrete production.

Previous: SMP Crusher

Next: SMP Crusher

Advantages of cone crusher production line in stone crushing operation

Advantages of cone crusher production line in stone crushing operation Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection

Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection What are the complete equipment of sand production line

What are the complete equipment of sand production line What equipment to use for crushing hard rock

What equipment to use for crushing hard rock What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost? Advantages of cone crusher production line in stone crushing operation

Advantages of cone crusher production line in stone crushing operation Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection

Liming 1.2 million tons per year crushing and sand making project: a model of intelligence, efficiency and green environmental protection What are the complete equipment of sand production line

What are the complete equipment of sand production line What equipment to use for crushing hard rock

What equipment to use for crushing hard rock What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost?