In the crushing process of hard rocks such as granite, basalt, and tuff, due to their high hardness (Mohs hardness of 6-7), high wear resistance, and high silicon content, the equipment wears quickly, the energy consumption is high, and the maintenance

In the crushing process of hard rocks such as granite, basalt, and tuff, due to their high hardness (Mohs hardness of 6-7), high wear resistance, and high silicon content, the equipment wears quickly, the energy consumption is high, and the maintenance cost is high. So what equipment should be used to crush hard rocks?

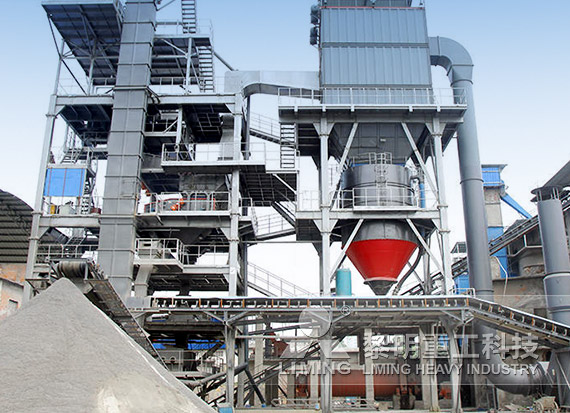

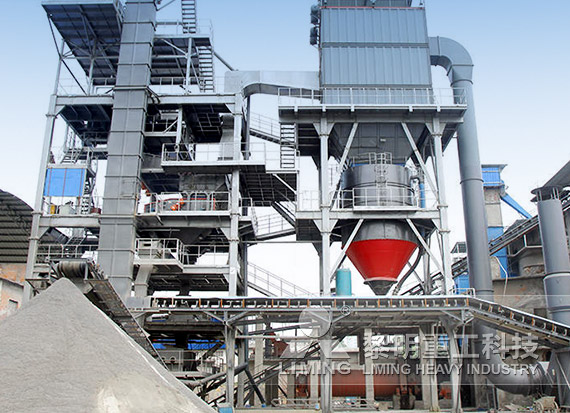

How to configure the equipment of a 1,000-ton gravel production line per hour, and how much does it cost?

1. Coarse crushing stage

General equipment: The jaw crusher adopts a deep cavity design with a high manganese steel jaw plate, which has a strong crushing capacity and can efficiently crush large pieces of raw ore to a particle size of 100-300mm.

Gyratory crusher: Excellent performance, single-machine processing capacity exceeds 2,000 tons/hour, can easily cope with the needs of ultra-large-scale mining crushing and sand and gravel processing projects, and can efficiently complete the crushing of large amounts of materials. However, its initial investment cost is relatively high, and it is suitable for projects with strong financial strength.

2. Medium and fine crushing stage

Laminated crushing equipment is preferred, which can greatly reduce equipment wear and tear, and has low maintenance costs in the later stage.

Large-scale sand and gravel production lines usually adopt: single-cylinder hydraulic cone crusher + multi-cylinder hydraulic cone crusher combined crushing mode, sharing the single-stage crushing pressure, higher crushing efficiency, better finished product particle shape, less needle-like.

3. Sand making stage

It is recommended to use a vertical shaft impact crusher with the function of switching between "stone hitting stone" and "stone hitting iron" crushing modes. The machine can flexibly switch modes, make full use of the interaction between stones for crushing, effectively reduce the direct impact and wear of stones on the machine, and extend the service life of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

In the crushing process of hard rocks such as granite, basalt, and tuff, due to their high hardness (Mohs hardness of 6-7), high wear resistance, and high silicon content, the equipment wears quickly, the energy consumption is high, and the maintenance

In the crushing process of hard rocks such as granite, basalt, and tuff, due to their high hardness (Mohs hardness of 6-7), high wear resistance, and high silicon content, the equipment wears quickly, the energy consumption is high, and the maintenance cost is high. So what equipment should be used to crush hard rocks?

How to configure the equipment of a 1,000-ton gravel production line per hour, and how much does it cost?

1. Coarse crushing stage

General equipment: The jaw crusher adopts a deep cavity design with a high manganese steel jaw plate, which has a strong crushing capacity and can efficiently crush large pieces of raw ore to a particle size of 100-300mm.

Gyratory crusher: Excellent performance, single-machine processing capacity exceeds 2,000 tons/hour, can easily cope with the needs of ultra-large-scale mining crushing and sand and gravel processing projects, and can efficiently complete the crushing of large amounts of materials. However, its initial investment cost is relatively high, and it is suitable for projects with strong financial strength.

2. Medium and fine crushing stage

Laminated crushing equipment is preferred, which can greatly reduce equipment wear and tear, and has low maintenance costs in the later stage.

Large-scale sand and gravel production lines usually adopt: single-cylinder hydraulic cone crusher + multi-cylinder hydraulic cone crusher combined crushing mode, sharing the single-stage crushing pressure, higher crushing efficiency, better finished product particle shape, less needle-like.

3. Sand making stage

It is recommended to use a vertical shaft impact crusher with the function of switching between "stone hitting stone" and "stone hitting iron" crushing modes. The machine can flexibly switch modes, make full use of the interaction between stones for crushing, effectively reduce the direct impact and wear of stones on the machine, and extend the service life of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost? Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line Large stone crusher equipment price

Large stone crusher equipment price Time production of 300 tons of stone crusher production line

Time production of 300 tons of stone crusher production line What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost? Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line Large stone crusher equipment price

Large stone crusher equipment price Time production of 300 tons of stone crusher production line

Time production of 300 tons of stone crusher production line