The following equipment is mainly used in the 300 tons per hour granite production line:Coarse crushing equipment: such as jaw crusher, plays a key role in granite crushing and sand making. This equipment is specifically responsible

The following equipment is mainly used in the 300 tons per hour granite production line:

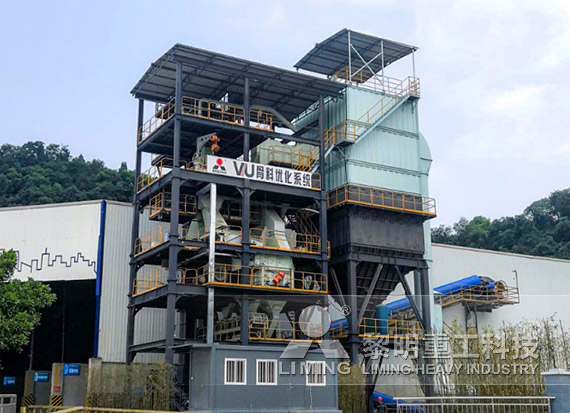

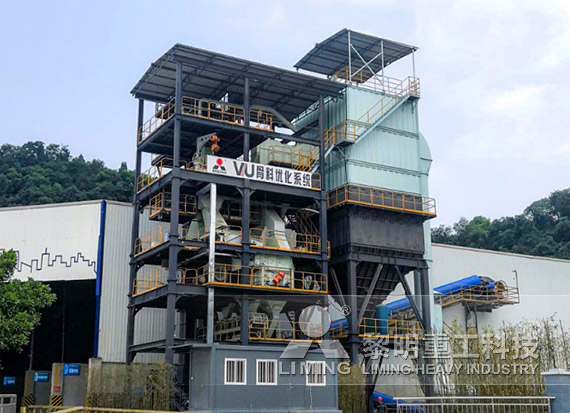

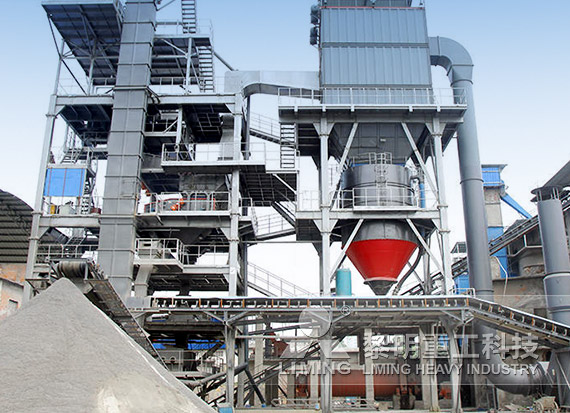

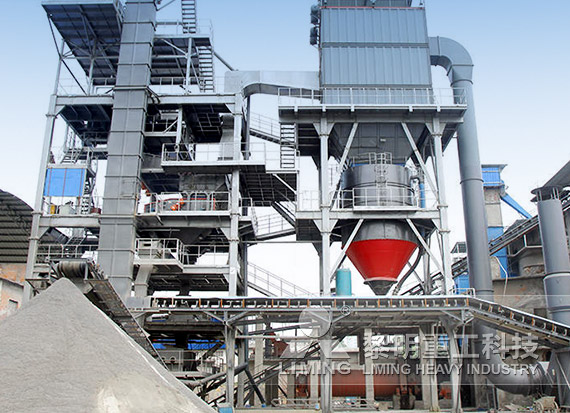

Coarse crushing equipment: such as jaw crusher, plays a key role in granite crushing and sand making. This equipment is specifically responsible for the preliminary treatment of large pieces of granite. With its powerful crushing ability, it crushes these large stones into smaller particles, providing materials of suitable particle size for subsequent crushing and sand making processes.

Medium and fine crushing equipment: such as cone crusher or impact crusher, further crushes the coarsely crushed granite into smaller particles.

Sand making equipment: such as impact sand making machine or vertical shaft sand making machine, processes the medium and fine crushed granite into sand products.

Screening equipment: such as vibrating screen, used to screen the mixed materials after sand making and separate the sand and gravel that meet the specifications.

Conveying equipment: such as belt conveyor, responsible for conveying materials between each process.

Sand washing equipment (optional): such as sand washing machine, used to clean the sand and gravel after sand making, remove the soil and impurities in it, and improve product quality.

Investment budget

The market price of a 300-ton per hour granite crushing and sand-making production line fluctuates greatly, and is significantly affected by factors such as equipment configuration, brand, and quality. Different equipment configurations, functions, and performances have different prices; well-known brands are often priced relatively high due to their technical and after-sales advantages; high-quality equipment costs are also higher. In general, the price range of a complete production line is wide, ranging from hundreds of thousands to millions, and the specific price needs to be determined based on the actual needs of the customer and the configuration plan.

Matters needing attention

When selecting production line equipment, many factors need to be considered comprehensively. The nature of the material is the basis, and different materials have different requirements for the material and processing methods of the equipment; the output requirements determine the scale and efficiency of the equipment, which need to match the production plan; the product quality is related to the accuracy and stability of the equipment. Only by considering these factors comprehensively can the stable and efficient operation of the production line be guaranteed. During production, equipment maintenance is indispensable. Regular inspection, cleaning, lubrication and other operations can ensure the normal operation of the equipment and extend its service life. In addition, it is necessary to attach great importance to production safety and environmental protection requirements, strictly abide by relevant standards, ensure production safety, reduce environmental pollution, and achieve sustainable production.

Previous: SMP Crusher

Next: SMP Crusher

The following equipment is mainly used in the 300 tons per hour granite production line:Coarse crushing equipment: such as jaw crusher, plays a key role in granite crushing and sand making. This equipment is specifically responsible

The following equipment is mainly used in the 300 tons per hour granite production line:

Coarse crushing equipment: such as jaw crusher, plays a key role in granite crushing and sand making. This equipment is specifically responsible for the preliminary treatment of large pieces of granite. With its powerful crushing ability, it crushes these large stones into smaller particles, providing materials of suitable particle size for subsequent crushing and sand making processes.

Medium and fine crushing equipment: such as cone crusher or impact crusher, further crushes the coarsely crushed granite into smaller particles.

Sand making equipment: such as impact sand making machine or vertical shaft sand making machine, processes the medium and fine crushed granite into sand products.

Screening equipment: such as vibrating screen, used to screen the mixed materials after sand making and separate the sand and gravel that meet the specifications.

Conveying equipment: such as belt conveyor, responsible for conveying materials between each process.

Sand washing equipment (optional): such as sand washing machine, used to clean the sand and gravel after sand making, remove the soil and impurities in it, and improve product quality.

Investment budget

The market price of a 300-ton per hour granite crushing and sand-making production line fluctuates greatly, and is significantly affected by factors such as equipment configuration, brand, and quality. Different equipment configurations, functions, and performances have different prices; well-known brands are often priced relatively high due to their technical and after-sales advantages; high-quality equipment costs are also higher. In general, the price range of a complete production line is wide, ranging from hundreds of thousands to millions, and the specific price needs to be determined based on the actual needs of the customer and the configuration plan.

Matters needing attention

When selecting production line equipment, many factors need to be considered comprehensively. The nature of the material is the basis, and different materials have different requirements for the material and processing methods of the equipment; the output requirements determine the scale and efficiency of the equipment, which need to match the production plan; the product quality is related to the accuracy and stability of the equipment. Only by considering these factors comprehensively can the stable and efficient operation of the production line be guaranteed. During production, equipment maintenance is indispensable. Regular inspection, cleaning, lubrication and other operations can ensure the normal operation of the equipment and extend its service life. In addition, it is necessary to attach great importance to production safety and environmental protection requirements, strictly abide by relevant standards, ensure production safety, reduce environmental pollution, and achieve sustainable production.

Previous: SMP Crusher

Next: SMP Crusher

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line Large stone crusher equipment price

Large stone crusher equipment price Time production of 300 tons of stone crusher production line

Time production of 300 tons of stone crusher production line How to increase the output of river pebble sand production line?

How to increase the output of river pebble sand production line? Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line Large stone crusher equipment price

Large stone crusher equipment price Time production of 300 tons of stone crusher production line

Time production of 300 tons of stone crusher production line How to increase the output of river pebble sand production line?

How to increase the output of river pebble sand production line?