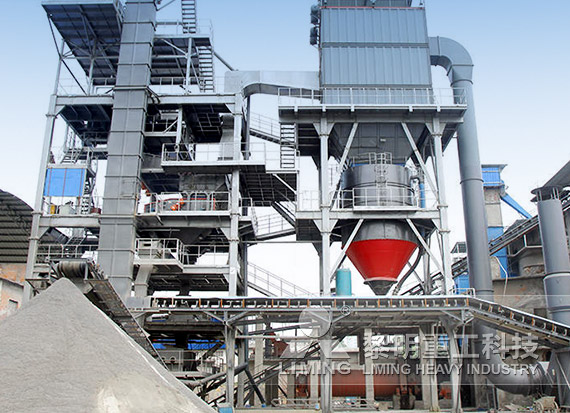

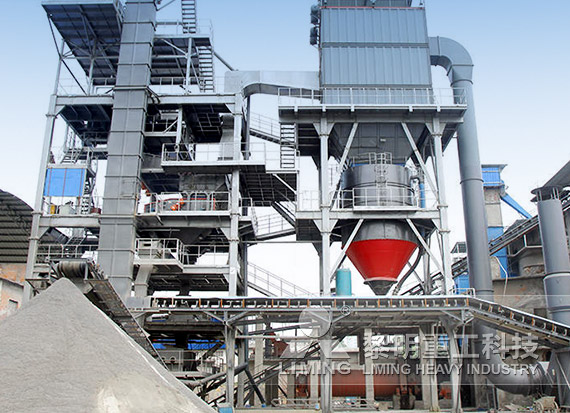

The complete set of equipment for the sand production line includes five stages: feeding, coarse crushing, fine crushing, sand making, screening, and sand washing. The corresponding main sand production equipment is as follows:1. The

The complete set of equipment for the sand production line includes five stages: feeding, coarse crushing, fine crushing, sand making, screening, and sand washing. The corresponding main sand production equipment is as follows:

1. The commonly used equipment for coarse crushing is the jaw crusher, but the traditional jaw crusher is prone to blockage and jaw plate breakage, which seriously affects the efficiency of the production line. Therefore, Hongji recommends that you use the European version of the jaw crusher, which has a steel plate toggle plate combined with a system of automatic shutdown when broken. Users no longer need to worry about durability and high maintenance costs. The crushing force of the European version of the jaw crusher is also large, with high output and excellent performance.

2. There are two options for fine crushing equipment: cone crusher and impact crusher. The difference between the two is that the cone crusher is laminated crushing, and the finished product particle shape is not as good as the impact crusher; the impact crusher is a percussion crushing, and its durability is slightly inferior to that of the cone crusher; if the hardness of the material you choose is high, the cone crusher is an ideal fine crushing equipment. On the contrary, if the material is brittle and has certain requirements for the particle shape, the impact crusher is trustworthy.

3. Sand making. The sand making machine adopts the principle of impact crushing. The material is continuously impacted and crushed in the crushing chamber of the stone-beating iron machine. The sand that comes out is round in shape and well graded, meeting the standards for construction sand.

4. Sand washing is responsible for the end of the entire production process. It removes the soil mixed in the sand, improves its quality and thus increases the selling price. The simple structure and working mode of the bucket wheel sand washing machine make it a popular cleaning equipment. The unique design of its transmission components is one of the main reasons for ensuring operation under harsh conditions. It is reliable and easy to maintain.

Previous: SMP Crusher

Next: SMP Crusher

The complete set of equipment for the sand production line includes five stages: feeding, coarse crushing, fine crushing, sand making, screening, and sand washing. The corresponding main sand production equipment is as follows:1. The

The complete set of equipment for the sand production line includes five stages: feeding, coarse crushing, fine crushing, sand making, screening, and sand washing. The corresponding main sand production equipment is as follows:

1. The commonly used equipment for coarse crushing is the jaw crusher, but the traditional jaw crusher is prone to blockage and jaw plate breakage, which seriously affects the efficiency of the production line. Therefore, Hongji recommends that you use the European version of the jaw crusher, which has a steel plate toggle plate combined with a system of automatic shutdown when broken. Users no longer need to worry about durability and high maintenance costs. The crushing force of the European version of the jaw crusher is also large, with high output and excellent performance.

2. There are two options for fine crushing equipment: cone crusher and impact crusher. The difference between the two is that the cone crusher is laminated crushing, and the finished product particle shape is not as good as the impact crusher; the impact crusher is a percussion crushing, and its durability is slightly inferior to that of the cone crusher; if the hardness of the material you choose is high, the cone crusher is an ideal fine crushing equipment. On the contrary, if the material is brittle and has certain requirements for the particle shape, the impact crusher is trustworthy.

3. Sand making. The sand making machine adopts the principle of impact crushing. The material is continuously impacted and crushed in the crushing chamber of the stone-beating iron machine. The sand that comes out is round in shape and well graded, meeting the standards for construction sand.

4. Sand washing is responsible for the end of the entire production process. It removes the soil mixed in the sand, improves its quality and thus increases the selling price. The simple structure and working mode of the bucket wheel sand washing machine make it a popular cleaning equipment. The unique design of its transmission components is one of the main reasons for ensuring operation under harsh conditions. It is reliable and easy to maintain.

Previous: SMP Crusher

Next: SMP Crusher

What equipment to use for crushing hard rock

What equipment to use for crushing hard rock What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost? Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line Large stone crusher equipment price

Large stone crusher equipment price What equipment to use for crushing hard rock

What equipment to use for crushing hard rock What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost? Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line Large stone crusher equipment price

Large stone crusher equipment price