The main component of barite is barium sulfate, generated in low-temperature hydrothermal veins, barite can also be generated in sedimentary rocks, appearing as nodules, mostly in sedimentary manganese deposits and shallow sea mud, sandy sedimentary ro

The main component of barite is barium sulfate, generated in low-temperature hydrothermal veins, barite can also be generated in sedimentary rocks, appearing as nodules, mostly in sedimentary manganese deposits and shallow sea mud, sandy sedimentary rocks. Barite is mostly in the form of large tubes, and when these tubular crystals are clustered together, they can form rosette shaped or bifurcated crystals called grossular barite. In general, barite is colorless, white, light yellow and other colors, with a glassy luster. Barite is chemically stable, insoluble in water and hydrochloric acid, non-magnetic and non-toxic.

Barite production and utilization

The general barite beneficiation methods are hand-selection, re-election, magnetic separation and flotation. Barite as a very important non-metallic mineral raw materials, has a very wide range of industrial uses, barite can be used for drilling mud weighting agent, zinc-barium white pigment, a variety of barium compounds, etc., barite can also be used for paint industry fillers, mineralizing agent for cement industry, anti-radiation cement, mortar and concrete and so on. In short, barite's wide range of applications greatly promote the development of production and life.

Barite magnetic separation process

Barite magnetic separator is mainly used for removing iron and purifying barite, and the recovery rate of barite magnetic separator produced by Redstar can reach more than 95%, which has the advantages of low maintenance rate, low energy consumption and high safety performance, and can bring higher economic benefits for users. Magnetic separator in the work, first by the feeding device will barite materials into the upper drum or drum lower, magnetic ore particles will be adsorbed to the surface of the drum under the action of magnetic force, around the edge of the magnetic system of the drum natural unloading, non-magnetic ore particles will fall into the role of gravity and centrifugal force into the different hopper, the two kinds of particles by the partition plate to separate, to achieve the purpose of removing iron.

Related equipment

Magnetic Separator

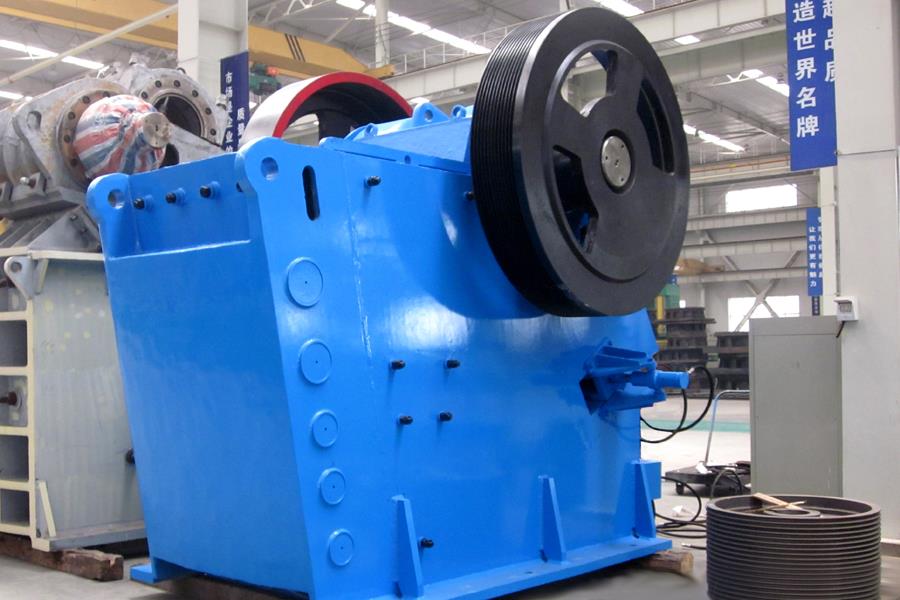

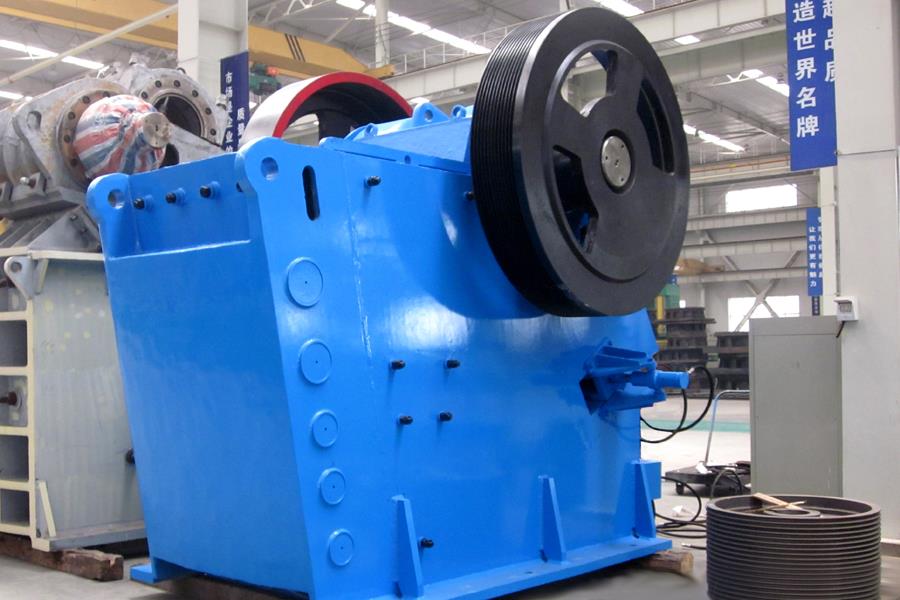

Previous: SMP Crusher

Next: SMP Crusher

The main component of barite is barium sulfate, generated in low-temperature hydrothermal veins, barite can also be generated in sedimentary rocks, appearing as nodules, mostly in sedimentary manganese deposits and shallow sea mud, sandy sedimentary ro

The main component of barite is barium sulfate, generated in low-temperature hydrothermal veins, barite can also be generated in sedimentary rocks, appearing as nodules, mostly in sedimentary manganese deposits and shallow sea mud, sandy sedimentary rocks. Barite is mostly in the form of large tubes, and when these tubular crystals are clustered together, they can form rosette shaped or bifurcated crystals called grossular barite. In general, barite is colorless, white, light yellow and other colors, with a glassy luster. Barite is chemically stable, insoluble in water and hydrochloric acid, non-magnetic and non-toxic.

Barite production and utilization

The general barite beneficiation methods are hand-selection, re-election, magnetic separation and flotation. Barite as a very important non-metallic mineral raw materials, has a very wide range of industrial uses, barite can be used for drilling mud weighting agent, zinc-barium white pigment, a variety of barium compounds, etc., barite can also be used for paint industry fillers, mineralizing agent for cement industry, anti-radiation cement, mortar and concrete and so on. In short, barite's wide range of applications greatly promote the development of production and life.

Barite magnetic separation process

Barite magnetic separator is mainly used for removing iron and purifying barite, and the recovery rate of barite magnetic separator produced by Redstar can reach more than 95%, which has the advantages of low maintenance rate, low energy consumption and high safety performance, and can bring higher economic benefits for users. Magnetic separator in the work, first by the feeding device will barite materials into the upper drum or drum lower, magnetic ore particles will be adsorbed to the surface of the drum under the action of magnetic force, around the edge of the magnetic system of the drum natural unloading, non-magnetic ore particles will fall into the role of gravity and centrifugal force into the different hopper, the two kinds of particles by the partition plate to separate, to achieve the purpose of removing iron.

Related equipment

Magnetic Separator

Previous: SMP Crusher

Next: SMP Crusher