The process of manganese oxide ore processing in China includes crushing, grinding and beneficiation, which is efficiently processed into finished products required in various fields by using advanced equipment and optimised process.The production line

The process of manganese oxide ore processing in China includes crushing, grinding and beneficiation, which is efficiently processed into finished products required in various fields by using advanced equipment and optimised process.The production line with C6X jawbreaker and HST cone crusher as the core equipment performs excellently, obtains high satisfaction from customers, and improves the production efficiency and product quality.

In China, the process of processing manganese oxide ore mainly includes three stages: crushing, grinding and beneficiation. Through advanced equipment and optimised process flow, manganese ore can be efficiently processed into finished products to meet the needs of various fields.

Process Flow

1. Crushing: Firstly, the ore is crushed to 6-0mm or 10-0mm, usually using a jaw crusher for primary crushing. This equipment, with its powerful crushing capacity and stable performance, ensures that the ore is effectively crushed to the required size.

2、Grouping and elimination: The crushed ore is grouped according to the particle size. Coarse grade ores are eliminated and fine grade ores are sent to shaking table for beneficiation.

3、Grinding: The crushed manganese ore is ground by longitudinal pendulum mill to produce finished products with specifications required in various fields.

4. Beneficiation: After grinding, the manganese ore is further processed by appropriate beneficiation process to extract the required mineral components.

Core processing equipment

In the processing of manganese ore, the core equipment includes:

Jaw Crusher: used for primary crushing, crushing large ore pieces to smaller size.

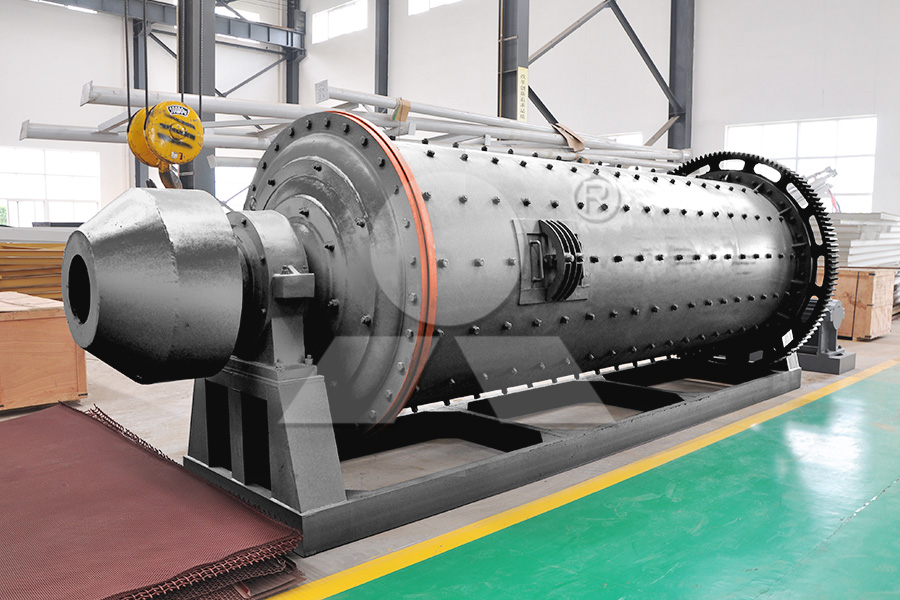

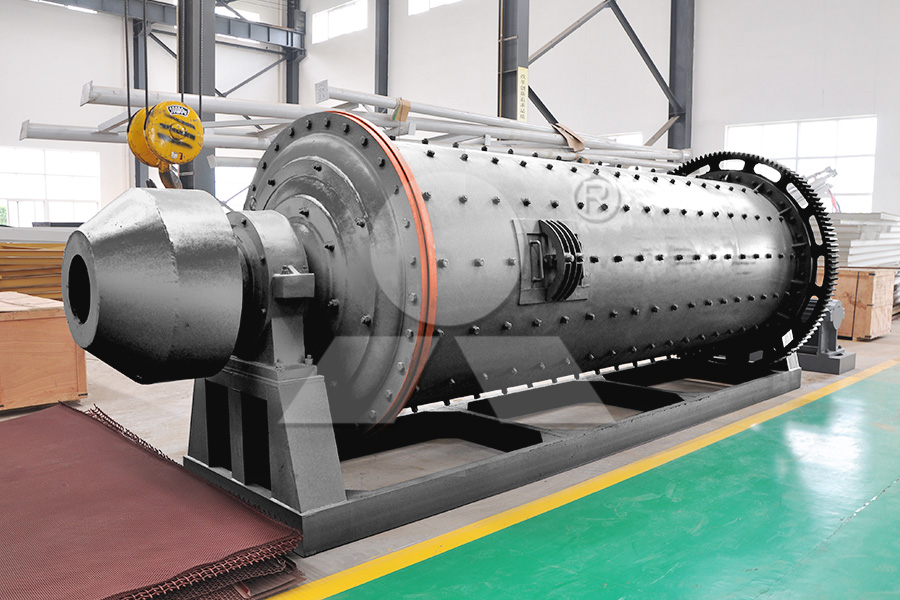

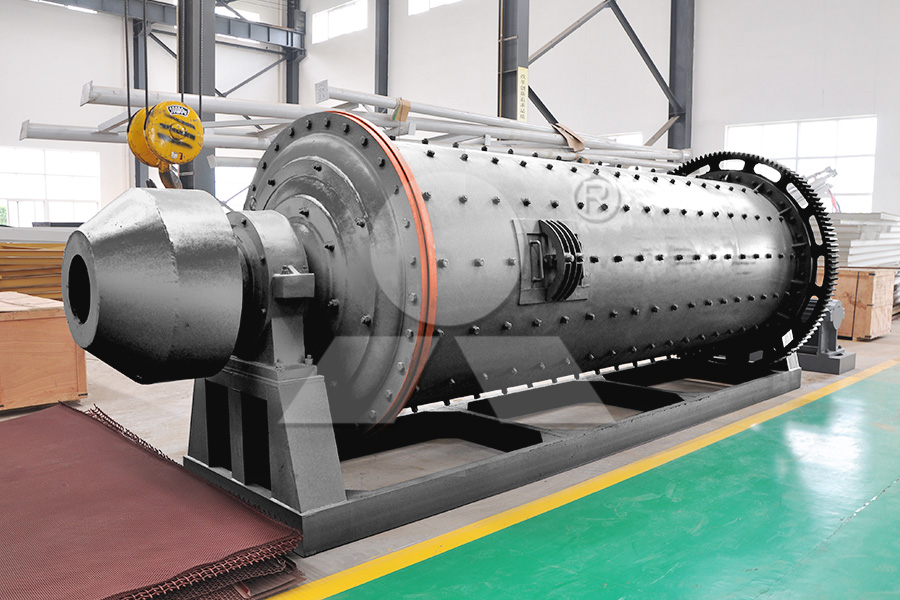

Longitudinal Pendulum Mill: used for grinding the crushed manganese ore to produce finished products with specifications that meet the needs of various fields.

Manganese Ore Processing Case

The following is a typical manganese ore processing case site:

Processed material: manganese ore

Capacity: 3000 tonnes/day

Equipment Configuration: One C6X Series High Energy Jaw Breaker + HST Series Single Cylinder Hydraulic Cone Crusher

In this project, the C6X series high-energy jaw crusher is used for primary crushing, followed by the HST series single-cylinder hydraulic cone crusher for secondary crushing. This configuration of the crushing system is not only highly efficient, but also ensures the ore size control, which makes the subsequent grinding and beneficiation process smoother.

Customer Feedback

Customers are highly satisfied with the high efficiency and stability of this manganese ore processing line. The excellent performance of the equipment and the scientific process not only improve the production efficiency, but also significantly improve the quality of the product, and achieve the expected economic benefits.

Conclusion

Through advanced crushing, grinding and beneficiation processes, China's manganese oxide ore treatment has achieved remarkable results. The production line with C6X series high-energy jaw breakers and HST series single-cylinder hydraulic cone breakers as the core equipment demonstrates its excellent performance in manganese ore processing and becomes an excellent case in the industry.

Previous: SMP Crusher

Next: SMP Crusher

The process of manganese oxide ore processing in China includes crushing, grinding and beneficiation, which is efficiently processed into finished products required in various fields by using advanced equipment and optimised process.The production line

The process of manganese oxide ore processing in China includes crushing, grinding and beneficiation, which is efficiently processed into finished products required in various fields by using advanced equipment and optimised process.The production line with C6X jawbreaker and HST cone crusher as the core equipment performs excellently, obtains high satisfaction from customers, and improves the production efficiency and product quality.

In China, the process of processing manganese oxide ore mainly includes three stages: crushing, grinding and beneficiation. Through advanced equipment and optimised process flow, manganese ore can be efficiently processed into finished products to meet the needs of various fields.

Process Flow

1. Crushing: Firstly, the ore is crushed to 6-0mm or 10-0mm, usually using a jaw crusher for primary crushing. This equipment, with its powerful crushing capacity and stable performance, ensures that the ore is effectively crushed to the required size.

2、Grouping and elimination: The crushed ore is grouped according to the particle size. Coarse grade ores are eliminated and fine grade ores are sent to shaking table for beneficiation.

3、Grinding: The crushed manganese ore is ground by longitudinal pendulum mill to produce finished products with specifications required in various fields.

4. Beneficiation: After grinding, the manganese ore is further processed by appropriate beneficiation process to extract the required mineral components.

Core processing equipment

In the processing of manganese ore, the core equipment includes:

Jaw Crusher: used for primary crushing, crushing large ore pieces to smaller size.

Longitudinal Pendulum Mill: used for grinding the crushed manganese ore to produce finished products with specifications that meet the needs of various fields.

Manganese Ore Processing Case

The following is a typical manganese ore processing case site:

Processed material: manganese ore

Capacity: 3000 tonnes/day

Equipment Configuration: One C6X Series High Energy Jaw Breaker + HST Series Single Cylinder Hydraulic Cone Crusher

In this project, the C6X series high-energy jaw crusher is used for primary crushing, followed by the HST series single-cylinder hydraulic cone crusher for secondary crushing. This configuration of the crushing system is not only highly efficient, but also ensures the ore size control, which makes the subsequent grinding and beneficiation process smoother.

Customer Feedback

Customers are highly satisfied with the high efficiency and stability of this manganese ore processing line. The excellent performance of the equipment and the scientific process not only improve the production efficiency, but also significantly improve the quality of the product, and achieve the expected economic benefits.

Conclusion

Through advanced crushing, grinding and beneficiation processes, China's manganese oxide ore treatment has achieved remarkable results. The production line with C6X series high-energy jaw breakers and HST series single-cylinder hydraulic cone breakers as the core equipment demonstrates its excellent performance in manganese ore processing and becomes an excellent case in the industry.

Previous: SMP Crusher

Next: SMP Crusher

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine How to configure 300 tonnes per hour manganese ore crushing production line

How to configure 300 tonnes per hour manganese ore crushing production line Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project

Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project Sichuan Gold Chooses Liming Group to Renovate Gold Ore Crushing Production Line

Sichuan Gold Chooses Liming Group to Renovate Gold Ore Crushing Production Line What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine How to configure 300 tonnes per hour manganese ore crushing production line

How to configure 300 tonnes per hour manganese ore crushing production line Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project

Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project Sichuan Gold Chooses Liming Group to Renovate Gold Ore Crushing Production Line

Sichuan Gold Chooses Liming Group to Renovate Gold Ore Crushing Production Line