With the increasing global consumption of natural resources, the rate of sand and gravel extraction has exceeded its natural replenishment rate, leading to a shortage of natural river sand. The British journal *Nature* points out that natural river san

With the increasing global consumption of natural resources, the rate of sand and gravel extraction has exceeded its natural replenishment rate, leading to a shortage of natural river sand. The British journal *Nature* points out that natural river sand is not inexhaustible; over-exploitation not only damages the environment, but government regulations on its extraction are also becoming increasingly stringent.

More Sand Making Production Lines

Applications of Manufactured Sand:

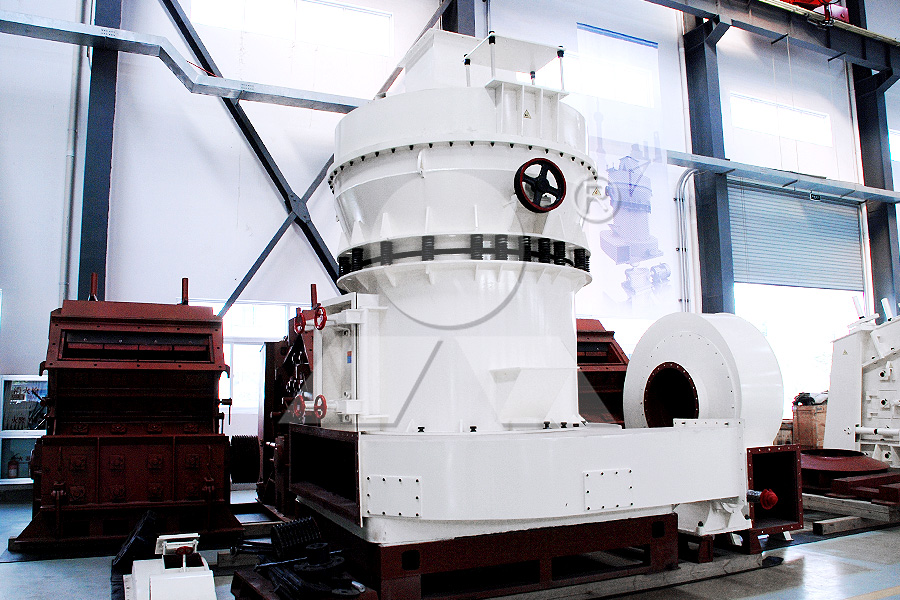

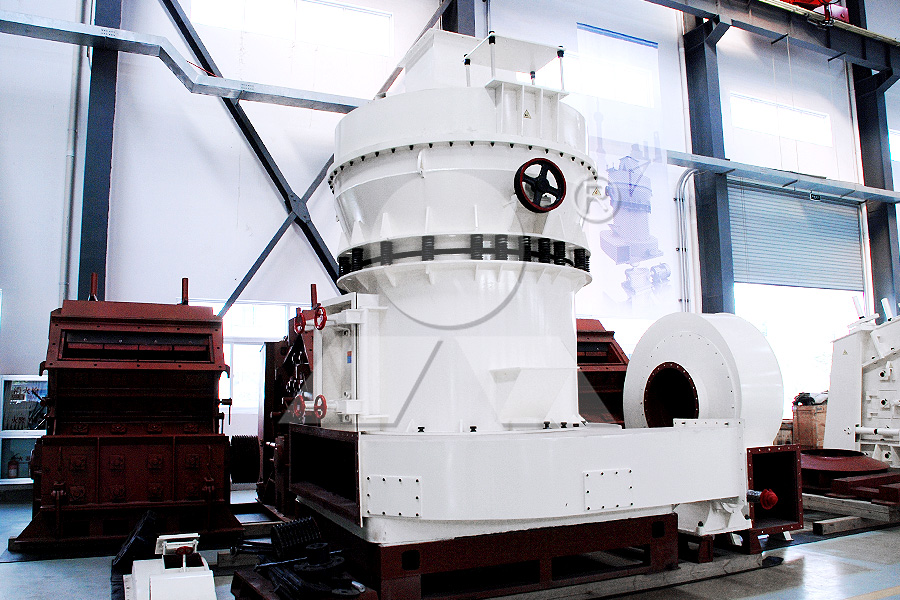

In this context, manufactured sand has gradually gained widespread acceptance as a substitute for natural river sand. Manufactured sand is granular material formed by processing rocks, mine tailings, or industrial waste using sand making machines and other equipment. Its wide range of raw material sources and controllable production processes give it a significant advantage in addressing resource scarcity and environmental protection issues.

Challenges and Solutions for the Application of Manufactured Sand in Concrete

Challenges: Manufactured sand in concrete applications suffers from problems such as slump loss, high water absorption, and unstable fineness modulus. These problems directly affect the workability and strength of concrete and require sufficient attention.

Solutions:

Parallel Rock Selection: Use hard rock with low water absorption and high strength as the raw material for manufactured sand.

Sand production process optimization: Through screening and shaping processes, the particle size and gradation of manufactured sand are improved, reducing the content of fine powder and clay.

Mix design: The saturated surface-dry method is adopted to precisely control the dosage of manufactured sand and the water-cement ratio, ensuring the stable performance of concrete.

Shibang Group is committed to solving various problems in the application of manufactured sand in concrete through technological innovation and equipment improvement, ensuring its widespread application and stable performance in construction projects.

Previous: SMP Crusher

Next: SMP Crusher

With the increasing global consumption of natural resources, the rate of sand and gravel extraction has exceeded its natural replenishment rate, leading to a shortage of natural river sand. The British journal *Nature* points out that natural river san

With the increasing global consumption of natural resources, the rate of sand and gravel extraction has exceeded its natural replenishment rate, leading to a shortage of natural river sand. The British journal *Nature* points out that natural river sand is not inexhaustible; over-exploitation not only damages the environment, but government regulations on its extraction are also becoming increasingly stringent.

More Sand Making Production Lines

Applications of Manufactured Sand:

In this context, manufactured sand has gradually gained widespread acceptance as a substitute for natural river sand. Manufactured sand is granular material formed by processing rocks, mine tailings, or industrial waste using sand making machines and other equipment. Its wide range of raw material sources and controllable production processes give it a significant advantage in addressing resource scarcity and environmental protection issues.

Challenges and Solutions for the Application of Manufactured Sand in Concrete

Challenges: Manufactured sand in concrete applications suffers from problems such as slump loss, high water absorption, and unstable fineness modulus. These problems directly affect the workability and strength of concrete and require sufficient attention.

Solutions:

Parallel Rock Selection: Use hard rock with low water absorption and high strength as the raw material for manufactured sand.

Sand production process optimization: Through screening and shaping processes, the particle size and gradation of manufactured sand are improved, reducing the content of fine powder and clay.

Mix design: The saturated surface-dry method is adopted to precisely control the dosage of manufactured sand and the water-cement ratio, ensuring the stable performance of concrete.

Shibang Group is committed to solving various problems in the application of manufactured sand in concrete through technological innovation and equipment improvement, ensuring its widespread application and stable performance in construction projects.

Previous: SMP Crusher

Next: SMP Crusher

How much does a complete set of construction waste treatment equipment cost, and how do I choose the right equipment?

How much does a complete set of construction waste treatment equipment cost, and how do I choose the right equipment? How much does a weathered sand making machine cost?

How much does a weathered sand making machine cost? Models and prices of single-cylinder cone crushers

Models and prices of single-cylinder cone crushers How much does a set of manufactured sand equipment cost?

How much does a set of manufactured sand equipment cost? What are the products of Shibang Mining Machinery?

What are the products of Shibang Mining Machinery? How much does a complete set of construction waste treatment equipment cost, and how do I choose the right equipment?

How much does a complete set of construction waste treatment equipment cost, and how do I choose the right equipment? How much does a weathered sand making machine cost?

How much does a weathered sand making machine cost? Models and prices of single-cylinder cone crushers

Models and prices of single-cylinder cone crushers How much does a set of manufactured sand equipment cost?

How much does a set of manufactured sand equipment cost? What are the products of Shibang Mining Machinery?

What are the products of Shibang Mining Machinery?