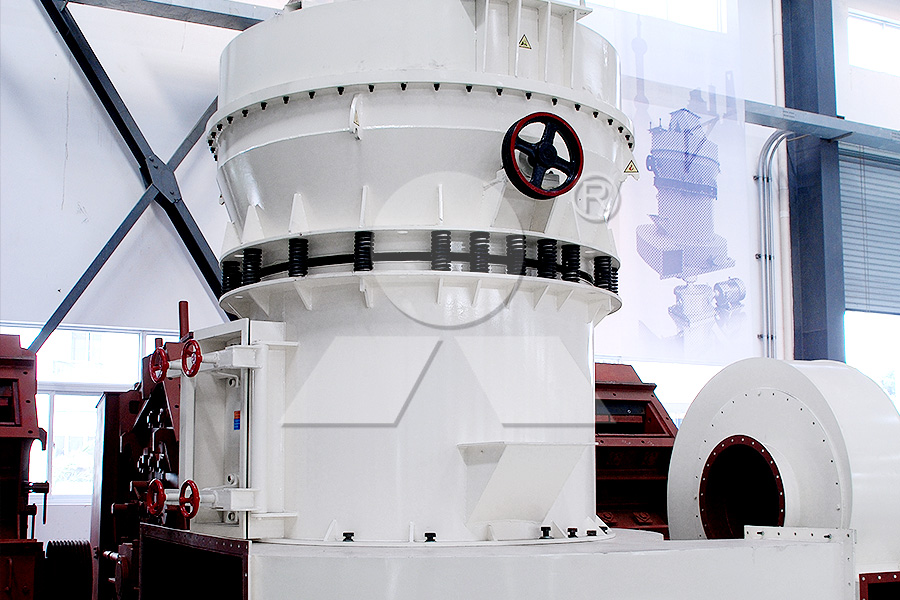

Overview of HGT Cyclic CrusherHGT rotary crusher integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies, benchmarking the international advanced level, is the 1 new type of coarse crushing equipment

Overview of HGT Cyclic Crusher

HGT rotary crusher integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies, benchmarking the international advanced level, is the 1 new type of coarse crushing equipment with large capacity, high efficiency and intelligence. Compared with the traditional gyratory crusher, HGT gyratory crusher has significant advantages in crushing efficiency, use cost and maintenance adjustment, providing users with efficient and intelligent large capacity coarse crushing solutions.

gyratory crusher price

Working principle

HGT rotary crusher is mainly composed of beam part, upper, middle and lower frame part, moving cone part, eccentric sleeve part, transmission part and hydraulic cylinder part. Its working principle is as follows:

The motor drives the horizontal shaft to rotate, the horizontal shaft drives the eccentric sleeve to rotate through the gear, and then the eccentric sleeve drives the moving cone to make a circular swing, so as to realize continuous extrusion and crushing of stones.

Adjusting the hydraulic cylinder located at the bottom of the moving cone can make the moving cone move up and down, so as to conveniently adjust the size of the ore discharge port and control the particle size of the product.

The hydraulic cylinder provides over-iron protection. When an object that cannot be broken (such as an iron block) enters the crushing chamber, the hydraulic cylinder can automatically make the moving cone fall, release the iron block, and protect the crusher.

Model parameters

HGT Cyclic Crushers are available in a variety of models to meet different production needs. The following are the main models and their parameters:

1. HGT4265

Moving cone diameter: 1650 mm

Feed inlet size: 1065 mm

outlet adjustment range: 140-175mm

Processing capacity: 2015-2875 tons/hour

Power: 400 kW

2. HGT5475

Moving cone diameter: 1905 mm

Feed inlet size: 1370 mm

Adjustment range of discharge port: 150-200mm

Processing capacity: 2890-3490 tons/hour

Power: 450 kW

3. HGT6089

Moving cone diameter: 2260 mm

Feed inlet size: 1525 mm

outlet adjustment range: 165-230mm

Processing capacity: 4200-5810 tons/hour

Power: 630 kW

4. HGT60110

Moving cone diameter: 2795 mm

Feed inlet size: 1525 mm

outlet adjustment range: 175-250mm

Processing capacity: 5540-8895 tons/hour

Power: 1250 kW

In the sand and gravel aggregate industry, Shibang Group has made important contributions to the development of the industry with its advanced HGT rotary crusher technology. The equipment of Shibang Group not only performs well in efficient production, but also has significant advantages in energy saving and environmental protection. With its intelligent and automated design, Sebang Group's rotary crusher greatly improves production efficiency, reduces operating costs, and provides customers with reliable production guarantee.

Previous: SMP Crusher

Next: SMP Crusher

Overview of HGT Cyclic CrusherHGT rotary crusher integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies, benchmarking the international advanced level, is the 1 new type of coarse crushing equipment

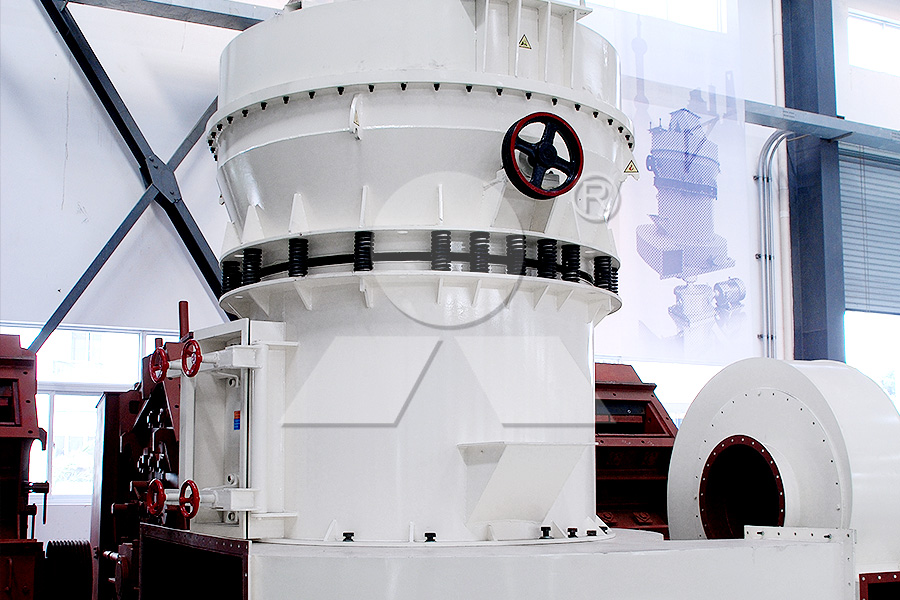

Overview of HGT Cyclic Crusher

HGT rotary crusher integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies, benchmarking the international advanced level, is the 1 new type of coarse crushing equipment with large capacity, high efficiency and intelligence. Compared with the traditional gyratory crusher, HGT gyratory crusher has significant advantages in crushing efficiency, use cost and maintenance adjustment, providing users with efficient and intelligent large capacity coarse crushing solutions.

gyratory crusher price

Working principle

HGT rotary crusher is mainly composed of beam part, upper, middle and lower frame part, moving cone part, eccentric sleeve part, transmission part and hydraulic cylinder part. Its working principle is as follows:

The motor drives the horizontal shaft to rotate, the horizontal shaft drives the eccentric sleeve to rotate through the gear, and then the eccentric sleeve drives the moving cone to make a circular swing, so as to realize continuous extrusion and crushing of stones.

Adjusting the hydraulic cylinder located at the bottom of the moving cone can make the moving cone move up and down, so as to conveniently adjust the size of the ore discharge port and control the particle size of the product.

The hydraulic cylinder provides over-iron protection. When an object that cannot be broken (such as an iron block) enters the crushing chamber, the hydraulic cylinder can automatically make the moving cone fall, release the iron block, and protect the crusher.

Model parameters

HGT Cyclic Crushers are available in a variety of models to meet different production needs. The following are the main models and their parameters:

1. HGT4265

Moving cone diameter: 1650 mm

Feed inlet size: 1065 mm

outlet adjustment range: 140-175mm

Processing capacity: 2015-2875 tons/hour

Power: 400 kW

2. HGT5475

Moving cone diameter: 1905 mm

Feed inlet size: 1370 mm

Adjustment range of discharge port: 150-200mm

Processing capacity: 2890-3490 tons/hour

Power: 450 kW

3. HGT6089

Moving cone diameter: 2260 mm

Feed inlet size: 1525 mm

outlet adjustment range: 165-230mm

Processing capacity: 4200-5810 tons/hour

Power: 630 kW

4. HGT60110

Moving cone diameter: 2795 mm

Feed inlet size: 1525 mm

outlet adjustment range: 175-250mm

Processing capacity: 5540-8895 tons/hour

Power: 1250 kW

In the sand and gravel aggregate industry, Shibang Group has made important contributions to the development of the industry with its advanced HGT rotary crusher technology. The equipment of Shibang Group not only performs well in efficient production, but also has significant advantages in energy saving and environmental protection. With its intelligent and automated design, Sebang Group's rotary crusher greatly improves production efficiency, reduces operating costs, and provides customers with reliable production guarantee.

Previous: SMP Crusher

Next: SMP Crusher

Introduction of river pebble sand making machine and manufacturer

Introduction of river pebble sand making machine and manufacturer Process Flow of 100-120 Tons of Limestone Fine Sand Production Line

Process Flow of 100-120 Tons of Limestone Fine Sand Production Line Large jaw crusher: ideal for efficient crushing

Large jaw crusher: ideal for efficient crushing What are the large sand making machines? How much is a set

What are the large sand making machines? How much is a set Concrete stone slag crusher: environmental protection and energy saving construction waste treatment equipment

Concrete stone slag crusher: environmental protection and energy saving construction waste treatment equipment Introduction of river pebble sand making machine and manufacturer

Introduction of river pebble sand making machine and manufacturer Process Flow of 100-120 Tons of Limestone Fine Sand Production Line

Process Flow of 100-120 Tons of Limestone Fine Sand Production Line Large jaw crusher: ideal for efficient crushing

Large jaw crusher: ideal for efficient crushing What are the large sand making machines? How much is a set

What are the large sand making machines? How much is a set Concrete stone slag crusher: environmental protection and energy saving construction waste treatment equipment

Concrete stone slag crusher: environmental protection and energy saving construction waste treatment equipment