Premium granite ballast production lines offer flexible configurations, with a jaw crusher and cone crusher combination meeting production capacity requirements of 100-400 t/h. Accurately matching equipment selection with production capacity is key to

Premium granite ballast production lines offer flexible configurations, with a jaw crusher and cone crusher combination meeting production capacity requirements of 100-400 t/h. Accurately matching equipment selection with production capacity is key to cost reduction.

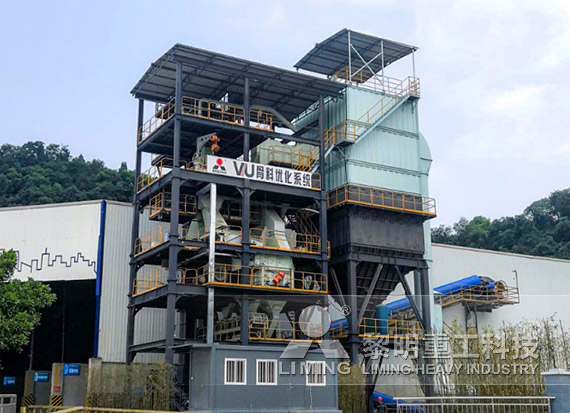

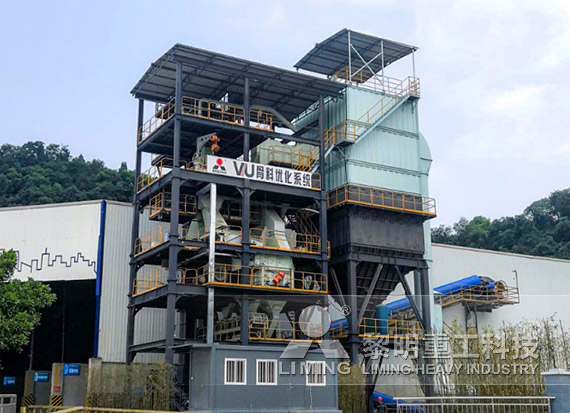

Ballast production is made from premium granite, which is relatively hard. For crushing, a jaw crusher is typically used as the primary crushing unit, with a cone crusher serving as the secondary and tertiary crushing equipment. Depending on the production capacity requirements, the configuration of the ballast crushing line varies, as illustrated below with an example.

Shibang Group

Crushing/Sand Making/Grinding Inquiry

Call Now

Case 1: Configuration of a 100-150t/h Ballast Crushing Production Line

This production line requires a ballast processing capacity of 100-150t/h, using premium granite as the raw material. The required equipment includes: a raw material silo, a magnetic separator, a vibrating screen, a cone crusher, two vibrating feeders, and a jaw crusher. These different pieces of equipment are combined into a specific production line to produce ballast according to production requirements.

Case 2: Configuration of a 150-180t/h Ballast Crushing Production Line

This production line requires a ballast processing capacity of 150-180t/h, using premium granite as the raw material. The required equipment includes: The main equipment includes: one raw material silo, two vibrating screens, one single-cylinder cone crusher, one iron remover, one jaw crusher, and one vibrating feeder. These different pieces of equipment are combined into a specific production line to produce ballast according to production requirements.

Case 3: Configuration of a 350-400 t/h Ballast Crushing Production Line

This production line requires a ballast processing capacity of 150-180 t/h, using premium granite as the raw material. The main equipment required includes: one high-level silo, one raw material silo, one iron remover, three vibrating screens, three cone crushers, five vibrating feeders, and one jaw crusher. These different pieces of equipment are combined into a specific production line to produce ballast according to production requirements.

Previous: SMP Crusher

Next: SMP Crusher

Premium granite ballast production lines offer flexible configurations, with a jaw crusher and cone crusher combination meeting production capacity requirements of 100-400 t/h. Accurately matching equipment selection with production capacity is key to

Premium granite ballast production lines offer flexible configurations, with a jaw crusher and cone crusher combination meeting production capacity requirements of 100-400 t/h. Accurately matching equipment selection with production capacity is key to cost reduction.

Ballast production is made from premium granite, which is relatively hard. For crushing, a jaw crusher is typically used as the primary crushing unit, with a cone crusher serving as the secondary and tertiary crushing equipment. Depending on the production capacity requirements, the configuration of the ballast crushing line varies, as illustrated below with an example.

Shibang Group

Crushing/Sand Making/Grinding Inquiry

Call Now

Case 1: Configuration of a 100-150t/h Ballast Crushing Production Line

This production line requires a ballast processing capacity of 100-150t/h, using premium granite as the raw material. The required equipment includes: a raw material silo, a magnetic separator, a vibrating screen, a cone crusher, two vibrating feeders, and a jaw crusher. These different pieces of equipment are combined into a specific production line to produce ballast according to production requirements.

Case 2: Configuration of a 150-180t/h Ballast Crushing Production Line

This production line requires a ballast processing capacity of 150-180t/h, using premium granite as the raw material. The required equipment includes: The main equipment includes: one raw material silo, two vibrating screens, one single-cylinder cone crusher, one iron remover, one jaw crusher, and one vibrating feeder. These different pieces of equipment are combined into a specific production line to produce ballast according to production requirements.

Case 3: Configuration of a 350-400 t/h Ballast Crushing Production Line

This production line requires a ballast processing capacity of 150-180 t/h, using premium granite as the raw material. The main equipment required includes: one high-level silo, one raw material silo, one iron remover, three vibrating screens, three cone crushers, five vibrating feeders, and one jaw crusher. These different pieces of equipment are combined into a specific production line to produce ballast according to production requirements.

Previous: SMP Crusher

Next: SMP Crusher

A New Journey for a Hydropower Power Nation: Shibang Group s Energy Responsibility from the Shuangjiangkou and Lianghekou Hydropower Stations

A New Journey for a Hydropower Power Nation: Shibang Group s Energy Responsibility from the Shuangjiangkou and Lianghekou Hydropower Stations Components of a complete sand and gravel aggregate production line

Components of a complete sand and gravel aggregate production line Shibang Chongqing 1,000-ton-per-hour aggregate processing project: setting a benchmark for efficient and environmentally friendly sand and gravel production

Shibang Chongqing 1,000-ton-per-hour aggregate processing project: setting a benchmark for efficient and environmentally friendly sand and gravel production What are the reasons for slow discharge of sand making machine?

What are the reasons for slow discharge of sand making machine? How to choose equipment for Shibangs 500 tons per hour tuff sand and gravel production line? What are the advantages of the project?

How to choose equipment for Shibangs 500 tons per hour tuff sand and gravel production line? What are the advantages of the project? A New Journey for a Hydropower Power Nation: Shibang Group s Energy Responsibility from the Shuangjiangkou and Lianghekou Hydropower Stations

A New Journey for a Hydropower Power Nation: Shibang Group s Energy Responsibility from the Shuangjiangkou and Lianghekou Hydropower Stations Components of a complete sand and gravel aggregate production line

Components of a complete sand and gravel aggregate production line Shibang Chongqing 1,000-ton-per-hour aggregate processing project: setting a benchmark for efficient and environmentally friendly sand and gravel production

Shibang Chongqing 1,000-ton-per-hour aggregate processing project: setting a benchmark for efficient and environmentally friendly sand and gravel production What are the reasons for slow discharge of sand making machine?

What are the reasons for slow discharge of sand making machine? How to choose equipment for Shibangs 500 tons per hour tuff sand and gravel production line? What are the advantages of the project?

How to choose equipment for Shibangs 500 tons per hour tuff sand and gravel production line? What are the advantages of the project?