In the context of resource recycling and green development, a customer in Shandong and Shibang Group have jointly built a solid waste crushing and sand making production line with an annual output of 3 million tons. The project uses mining waste and co

In the context of resource recycling and green development, a customer in Shandong and Shibang Group have jointly built a solid waste crushing and sand making production line with an annual output of 3 million tons. The project uses mining waste and construction waste as raw materials, and produces recycled aggregates through advanced crushing and sand making processes, which are widely used in concrete production and mine backfilling, achieving a win-win situation of economic and ecological benefits.

Click to consult to learn about the construction plan of the sand and gravel aggregate production line

Project Overview

The main raw materials of the production line are mining waste and construction waste, with an annual processing capacity of up to 3 million tons. After crushing, screening, sand making and other processes, 80% of the solid waste is converted into high-quality recycled aggregates for concrete production, reducing dependence on natural sand and gravel resources; the remaining 20% of the waste slag becomes an ideal material for mine backfilling due to its excellent permeability.

Core equipment:

In order to ensure the stable operation of the production line and the high quality of the finished products, Shibang Group has configured a number of advanced crushing equipment for the project:

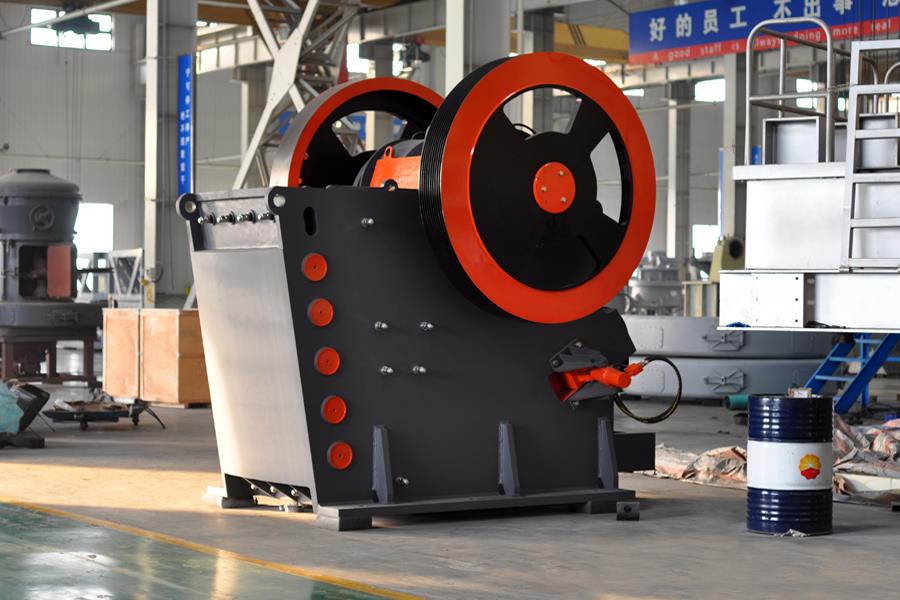

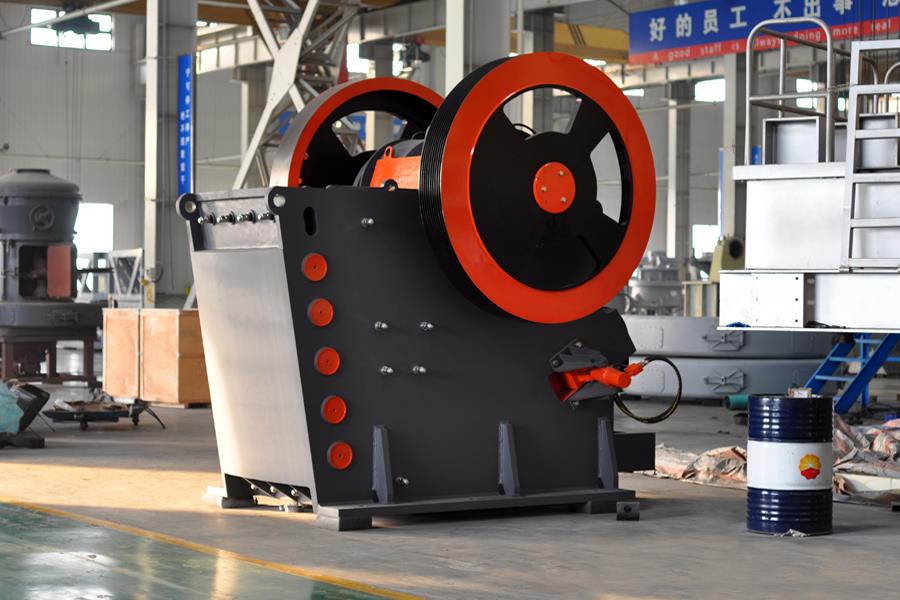

1. PEW jaw crusher: As the primary crushing equipment, it has the characteristics of solid structure and strong processing capacity, and can efficiently crush mining waste and construction waste.

2. HST single-cylinder hydraulic cone crusher: used in the medium and fine crushing stage, it has the advantages of high crushing efficiency and low energy consumption, ensuring the particle size and quality of aggregates.

3. VSI6X vertical shaft impact crusher: As the core equipment for sand making, it adopts the crushing principle of combining "stone hitting stone" and "stone hitting iron", and the recycled aggregate produced has excellent particle shape and reasonable gradation, which fully meets the needs of concrete production.

Project advantages

1. Recycling, economic and environmental protection

Through scientific treatment, 80% of solid waste is converted into recycled aggregate, reducing the pressure on the exploitation of natural resources; the remaining waste slag is used for backfilling the mine pit, realizing the full recycling of resources. This model not only reduces production costs, but also reduces damage to the environment, which meets the requirements of green mine development.

2. Reasonable design, low dust and low noise

The production line adopts a sunken design, and the production area is located 20 meters underground, realizing fully sealed production. At the same time, it is equipped with efficient dust removal equipment to ensure zero pollution and dust-free production process. This design not only reduces the impact of noise on the surrounding environment, but also establishes a green and environmentally friendly image for the company.

3. Advanced equipment and high economic benefits

The production line adopts high-performance equipment provided by Shibang Group, which can efficiently process mining waste and construction waste, with an annual processing capacity of up to 3 million tons. The implementation of this project not only brings considerable economic benefits to customers, but also injects new vitality into regional economic development.

4. Intelligent monitoring to ensure quality

In order to improve the operating efficiency and quality control of the production line, the project introduces an intelligent control system and a real-time monitoring system for the entire process. Through intelligent management and precise control, it not only reduces labor costs, but also ensures the efficient operation of equipment and the high quality of finished products.

This project is another successful cooperation between Shibang Group and its customers, which fully reflects the common concept of both parties in the field of green mining development and resource recycling. Through scientific planning and advanced equipment configuration, the project not only achieves efficient utilization of waste, but also provides new ideas and models for mine development. In the future, Shibang Group will continue to uphold the development concept of "green, intelligent, and efficient", provide customers with better equipment and services, help more companies achieve dual economic and ecological benefits, and contribute to promoting the sustainable development of the industry.

Previous: SMP Crusher

Next: SMP Crusher

In the context of resource recycling and green development, a customer in Shandong and Shibang Group have jointly built a solid waste crushing and sand making production line with an annual output of 3 million tons. The project uses mining waste and co

In the context of resource recycling and green development, a customer in Shandong and Shibang Group have jointly built a solid waste crushing and sand making production line with an annual output of 3 million tons. The project uses mining waste and construction waste as raw materials, and produces recycled aggregates through advanced crushing and sand making processes, which are widely used in concrete production and mine backfilling, achieving a win-win situation of economic and ecological benefits.

Click to consult to learn about the construction plan of the sand and gravel aggregate production line

Project Overview

The main raw materials of the production line are mining waste and construction waste, with an annual processing capacity of up to 3 million tons. After crushing, screening, sand making and other processes, 80% of the solid waste is converted into high-quality recycled aggregates for concrete production, reducing dependence on natural sand and gravel resources; the remaining 20% of the waste slag becomes an ideal material for mine backfilling due to its excellent permeability.

Core equipment:

In order to ensure the stable operation of the production line and the high quality of the finished products, Shibang Group has configured a number of advanced crushing equipment for the project:

1. PEW jaw crusher: As the primary crushing equipment, it has the characteristics of solid structure and strong processing capacity, and can efficiently crush mining waste and construction waste.

2. HST single-cylinder hydraulic cone crusher: used in the medium and fine crushing stage, it has the advantages of high crushing efficiency and low energy consumption, ensuring the particle size and quality of aggregates.

3. VSI6X vertical shaft impact crusher: As the core equipment for sand making, it adopts the crushing principle of combining "stone hitting stone" and "stone hitting iron", and the recycled aggregate produced has excellent particle shape and reasonable gradation, which fully meets the needs of concrete production.

Project advantages

1. Recycling, economic and environmental protection

Through scientific treatment, 80% of solid waste is converted into recycled aggregate, reducing the pressure on the exploitation of natural resources; the remaining waste slag is used for backfilling the mine pit, realizing the full recycling of resources. This model not only reduces production costs, but also reduces damage to the environment, which meets the requirements of green mine development.

2. Reasonable design, low dust and low noise

The production line adopts a sunken design, and the production area is located 20 meters underground, realizing fully sealed production. At the same time, it is equipped with efficient dust removal equipment to ensure zero pollution and dust-free production process. This design not only reduces the impact of noise on the surrounding environment, but also establishes a green and environmentally friendly image for the company.

3. Advanced equipment and high economic benefits

The production line adopts high-performance equipment provided by Shibang Group, which can efficiently process mining waste and construction waste, with an annual processing capacity of up to 3 million tons. The implementation of this project not only brings considerable economic benefits to customers, but also injects new vitality into regional economic development.

4. Intelligent monitoring to ensure quality

In order to improve the operating efficiency and quality control of the production line, the project introduces an intelligent control system and a real-time monitoring system for the entire process. Through intelligent management and precise control, it not only reduces labor costs, but also ensures the efficient operation of equipment and the high quality of finished products.

This project is another successful cooperation between Shibang Group and its customers, which fully reflects the common concept of both parties in the field of green mining development and resource recycling. Through scientific planning and advanced equipment configuration, the project not only achieves efficient utilization of waste, but also provides new ideas and models for mine development. In the future, Shibang Group will continue to uphold the development concept of "green, intelligent, and efficient", provide customers with better equipment and services, help more companies achieve dual economic and ecological benefits, and contribute to promoting the sustainable development of the industry.

Previous: SMP Crusher

Next: SMP Crusher

How to solve the blockage of cone crusher

How to solve the blockage of cone crusher What are the price factors of a complete set of granite sand making equipment

What are the price factors of a complete set of granite sand making equipment Impact crusher models with an hourly output of more than 300 tons, how much does one cost

Impact crusher models with an hourly output of more than 300 tons, how much does one cost What are the types of sand making machines? How much does one cost?

What are the types of sand making machines? How much does one cost? What are the methods to reduce the energy consumption of cone crusher?

What are the methods to reduce the energy consumption of cone crusher? How to solve the blockage of cone crusher

How to solve the blockage of cone crusher What are the price factors of a complete set of granite sand making equipment

What are the price factors of a complete set of granite sand making equipment Impact crusher models with an hourly output of more than 300 tons, how much does one cost

Impact crusher models with an hourly output of more than 300 tons, how much does one cost What are the types of sand making machines? How much does one cost?

What are the types of sand making machines? How much does one cost? What are the methods to reduce the energy consumption of cone crusher?

What are the methods to reduce the energy consumption of cone crusher?