The 500-ton-per-hour river dredging project in Suichang County, Lishui City, Zhejiang Province, utilizes Shibang Group's customized wet process, achieving flexible production, an environmentally friendly closed-loop system, and efficient resource u

The 500-ton-per-hour river dredging project in Suichang County, Lishui City, Zhejiang Province, utilizes Shibang Group's customized wet process, achieving flexible production, an environmentally friendly closed-loop system, and efficient resource utilization. With a yield rate of 93%, the project not only restores the ecology but also empowers infrastructure, creating a win-win model for the fusion of green waters and lush mountains with valuable assets.

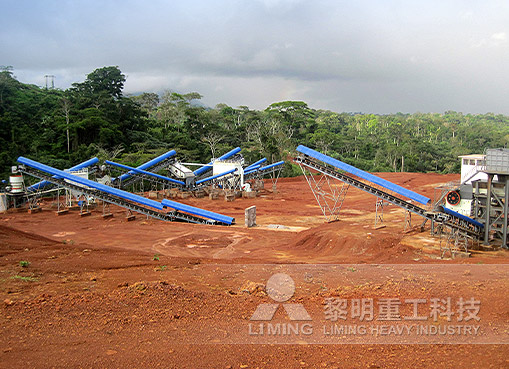

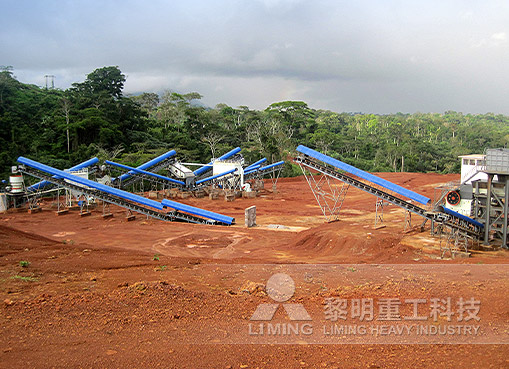

Lishui, Zhejiang Province, an ecological city surrounded by lush green mountains and clear waters, has completed the 500-ton-per-hour river dredging and comprehensive utilization project in Suichang County, Lishui City, Zhejiang Province, in order to further implement the ecological civilization concept of "Green waters and lush mountains are valuable assets," strengthen river management, improve urban and rural water environments, and maximize the comprehensive benefits of rivers and lakes.

Shibang Group

Crushing/Sand Making/Grinding Inquiry

Call Now

Project Information

Process: Wet Process

Capacity: 450-500 tons/hour

Raw Materials: River Pebbles (River Dredging)

Equipment: PEW Jaw Crusher, HST250 Single-Cylinder Hydraulic Cone Crusher, HPT500 Multi-Cylinder Hydraulic Cone Crusher, VSI6X1150 Impact Crusher, S5X Circular Vibrating Screen, F5X Feeder, SP Vibrating Feeder, etc.

Taking advantage of the high hardness and high mud content of river pebbles in river dredged materials, Shibang Group has developed a customized wet processing system. This system, centered around a "three-stage crushing + one-stage sand making" process, utilizes core equipment such as PEW jaw crushers, HST single-cylinder hydraulic cone crushers, and HPT multi-cylinder hydraulic cone crushers to create a flexible production line.

This solution achieves three major breakthroughs: First, its flexible design supports dual-mode switching between "full sand production" and "sand production + shaping," dynamically adapting to market demand. Second, its wet processing technology ensures the cleanliness of the finished product. Wastewater generated during the wet process is centrally processed and purified in the sludge treatment workshop, ensuring compliance with environmental standards. Third, its precise crushing process enables the precise production of four aggregate sizes: 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm. The yield rate reaches 93%, and the system maintains a stable production capacity of 450-500 tons/hour. This ensures the supply of raw materials for infrastructure construction while ensuring efficient utilization of every resource.

Technical Highlights

Intensive Spatial Layout: Equipment layout is optimized based on the terrain, minimizing floor space while maximizing storage capacity for raw and finished materials. This ensures continuous production and allows for flexible response to market fluctuations.

Flexible production model: The crushing stage can directly produce finished products through a cone crusher, eliminating redundant steps. The finished product storage is equipped with a conveyor belt for unloading trolleys, enabling flexible stacking of machine-made sand in multiple storage areas to meet diverse order requirements.

Intelligent equipment performance: The multi-cylinder hydraulic cone crusher features high speeds and a wide-angle crushing chamber for enhanced layered crushing, improving finished product particle size and output. The PLC automated control system, linked to a central operating station, enables equipment interlocking, parameter monitoring, and remote control, reducing labor intensity and ensuring stable operation.

Closed-loop environmental standards: The entire process utilizes a modular design, and a supporting sewage treatment system ensures water recycling and zero pollution emissions, adhering to green mine construction standards.

Under the scientific planning of Shibang Group, the project has upgraded a traditional dredging project into a green project integrating ecological restoration, sand and gravel production, and resource recycling. Since its commissioning, it has not only effectively improved the local water environment and achieved its established ecological benefit goals, but also provided high-quality sand and gravel aggregates for local infrastructure construction and ready-mixed concrete companies, achieving both ecological and economic value.

From solution customization to commissioning and operations, Shibang Group, leveraging its "2025 Zhejiang Service" initiative, continuously integrates intelligent and low-carbon technologies into its projects, helping clients achieve a dynamic balance between ecological protection and resource utilization.

"Our clients' success is our success." Shibang's collaborations extend beyond project implementation; we are committed to transforming every investment into long-term momentum for our clients' sustainable development.

Previous: SMP Crusher

Next: SMP Crusher

The 500-ton-per-hour river dredging project in Suichang County, Lishui City, Zhejiang Province, utilizes Shibang Group's customized wet process, achieving flexible production, an environmentally friendly closed-loop system, and efficient resource u

The 500-ton-per-hour river dredging project in Suichang County, Lishui City, Zhejiang Province, utilizes Shibang Group's customized wet process, achieving flexible production, an environmentally friendly closed-loop system, and efficient resource utilization. With a yield rate of 93%, the project not only restores the ecology but also empowers infrastructure, creating a win-win model for the fusion of green waters and lush mountains with valuable assets.

Lishui, Zhejiang Province, an ecological city surrounded by lush green mountains and clear waters, has completed the 500-ton-per-hour river dredging and comprehensive utilization project in Suichang County, Lishui City, Zhejiang Province, in order to further implement the ecological civilization concept of "Green waters and lush mountains are valuable assets," strengthen river management, improve urban and rural water environments, and maximize the comprehensive benefits of rivers and lakes.

Shibang Group

Crushing/Sand Making/Grinding Inquiry

Call Now

Project Information

Process: Wet Process

Capacity: 450-500 tons/hour

Raw Materials: River Pebbles (River Dredging)

Equipment: PEW Jaw Crusher, HST250 Single-Cylinder Hydraulic Cone Crusher, HPT500 Multi-Cylinder Hydraulic Cone Crusher, VSI6X1150 Impact Crusher, S5X Circular Vibrating Screen, F5X Feeder, SP Vibrating Feeder, etc.

Taking advantage of the high hardness and high mud content of river pebbles in river dredged materials, Shibang Group has developed a customized wet processing system. This system, centered around a "three-stage crushing + one-stage sand making" process, utilizes core equipment such as PEW jaw crushers, HST single-cylinder hydraulic cone crushers, and HPT multi-cylinder hydraulic cone crushers to create a flexible production line.

This solution achieves three major breakthroughs: First, its flexible design supports dual-mode switching between "full sand production" and "sand production + shaping," dynamically adapting to market demand. Second, its wet processing technology ensures the cleanliness of the finished product. Wastewater generated during the wet process is centrally processed and purified in the sludge treatment workshop, ensuring compliance with environmental standards. Third, its precise crushing process enables the precise production of four aggregate sizes: 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm. The yield rate reaches 93%, and the system maintains a stable production capacity of 450-500 tons/hour. This ensures the supply of raw materials for infrastructure construction while ensuring efficient utilization of every resource.

Technical Highlights

Intensive Spatial Layout: Equipment layout is optimized based on the terrain, minimizing floor space while maximizing storage capacity for raw and finished materials. This ensures continuous production and allows for flexible response to market fluctuations.

Flexible production model: The crushing stage can directly produce finished products through a cone crusher, eliminating redundant steps. The finished product storage is equipped with a conveyor belt for unloading trolleys, enabling flexible stacking of machine-made sand in multiple storage areas to meet diverse order requirements.

Intelligent equipment performance: The multi-cylinder hydraulic cone crusher features high speeds and a wide-angle crushing chamber for enhanced layered crushing, improving finished product particle size and output. The PLC automated control system, linked to a central operating station, enables equipment interlocking, parameter monitoring, and remote control, reducing labor intensity and ensuring stable operation.

Closed-loop environmental standards: The entire process utilizes a modular design, and a supporting sewage treatment system ensures water recycling and zero pollution emissions, adhering to green mine construction standards.

Under the scientific planning of Shibang Group, the project has upgraded a traditional dredging project into a green project integrating ecological restoration, sand and gravel production, and resource recycling. Since its commissioning, it has not only effectively improved the local water environment and achieved its established ecological benefit goals, but also provided high-quality sand and gravel aggregates for local infrastructure construction and ready-mixed concrete companies, achieving both ecological and economic value.

From solution customization to commissioning and operations, Shibang Group, leveraging its "2025 Zhejiang Service" initiative, continuously integrates intelligent and low-carbon technologies into its projects, helping clients achieve a dynamic balance between ecological protection and resource utilization.

"Our clients' success is our success." Shibang's collaborations extend beyond project implementation; we are committed to transforming every investment into long-term momentum for our clients' sustainable development.

Previous: SMP Crusher

Next: SMP Crusher

Shibang builds a high-quality aggregate base for Zhejiang Communications Investment Group, helping mines in western Zhejiang to turn green and generate gold.

Shibang builds a high-quality aggregate base for Zhejiang Communications Investment Group, helping mines in western Zhejiang to turn green and generate gold. What are the reasons for the rocking phenomenon during the operation of the river pebble sand making machine

What are the reasons for the rocking phenomenon during the operation of the river pebble sand making machine Shibangs 600-ton-per-hour sand-making equipment provides high-quality aggregates for the construction of a hydropower station in Sichuan

Shibangs 600-ton-per-hour sand-making equipment provides high-quality aggregates for the construction of a hydropower station in Sichuan What are the reasons for unstable operation of mobile stone crusher?

What are the reasons for unstable operation of mobile stone crusher? SBM Sichuans 1,000-ton-per-hour sand and gravel production line supports the construction of Shuangjiangkou Hydropower Station

SBM Sichuans 1,000-ton-per-hour sand and gravel production line supports the construction of Shuangjiangkou Hydropower Station Shibang builds a high-quality aggregate base for Zhejiang Communications Investment Group, helping mines in western Zhejiang to turn green and generate gold.

Shibang builds a high-quality aggregate base for Zhejiang Communications Investment Group, helping mines in western Zhejiang to turn green and generate gold. What are the reasons for the rocking phenomenon during the operation of the river pebble sand making machine

What are the reasons for the rocking phenomenon during the operation of the river pebble sand making machine Shibangs 600-ton-per-hour sand-making equipment provides high-quality aggregates for the construction of a hydropower station in Sichuan

Shibangs 600-ton-per-hour sand-making equipment provides high-quality aggregates for the construction of a hydropower station in Sichuan What are the reasons for unstable operation of mobile stone crusher?

What are the reasons for unstable operation of mobile stone crusher? SBM Sichuans 1,000-ton-per-hour sand and gravel production line supports the construction of Shuangjiangkou Hydropower Station

SBM Sichuans 1,000-ton-per-hour sand and gravel production line supports the construction of Shuangjiangkou Hydropower Station