The steel slag crushing production line responds to the national energy conservation and environmental protection policy and uses equipment such as jaw crushers and cone crushers to efficiently process steel slag and realize resource recycling an

The steel slag crushing production line responds to the national energy conservation and environmental protection policy and uses equipment such as jaw crushers and cone crushers to efficiently process steel slag and realize resource recycling and reuse. It can be used in many fields, has significant economic benefits, reduces environmental pollution, and promotes the development of circular economy.

Abstract generated by the author through intelligent technology

it works

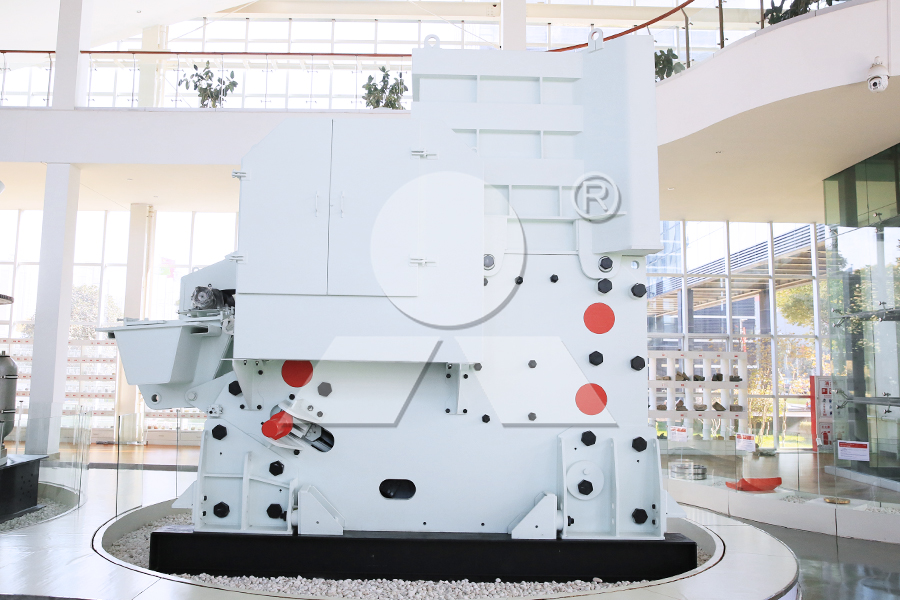

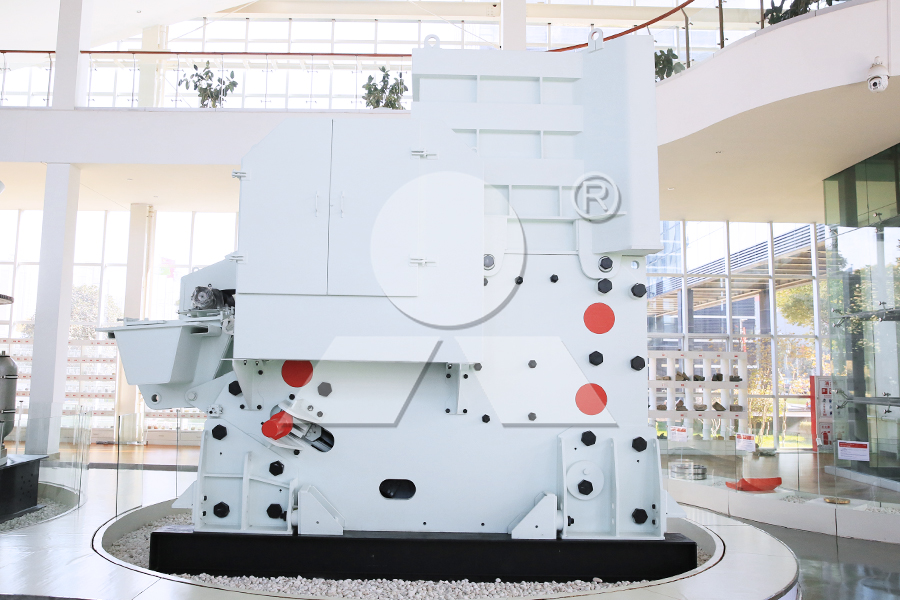

The steel slag crushing production line is in response to the national energy conservation and environmental protection policy. According to the hardness characteristics of steel slag, the equipment is reasonably configured to realize the resource recycling and reuse of steel slag.

Details of steel slag recycling equipment

1. Applicable materials and application fields

Applicable materials: steel slag

Application fields: The processed steel slag can be used in a variety of fields, such as smelting solvents, cement raw materials, construction aggregates, railway ballast, foundation backfill, brick and tile materials, steel slag fertilizers and soil conditioners, etc.

2. Equipment configuration and process flow

Main equipment: vibrating feeder, jaw crusher, hydraulic cone crusher, vibrating screen, belt conveyor, iron remover, etc.

Process flow: The raw materials pass through the vibrating feeder, are classified according to particle size, and then enter the jaw crusher and cone crusher for secondary crushing. During the crushing process, an iron remover is used to extract iron blocks from the steel slag. The crushed materials are screened by the vibrating screen, and the finished products that meet the standards are directly output, while the unqualified materials are returned to the crusher for reprocessing.

3. Economic benefits of steel slag reuse

Steel slag is a solid waste in steel production. After crushing, it can not only recover steel resources, but can also be used in construction materials, road paving, brick manufacturing and other fields, significantly improving economic and environmental benefits. In particular, the recyclable iron content in steel slag can reach 7%-15%. The comprehensive utilization of steel slag has become an important way to realize waste resource utilization.

4. Equipment performance advantages

This production line uses jaw crushers and hydraulic cone crushers, which have the characteristics of high crushing efficiency, low energy consumption, and high degree of automation. In addition, the equipment has excellent wear resistance and low overall operating costs.

5. Technical support and flexible design

Shanmei Company provides customized process solutions and technical support based on customer needs, and makes adjustments based on actual on-site conditions to ensure that steel slag treatment achieves the ideal effect.

6. Environmentally friendly and efficient processing technology

Through advanced iron removal, screening, and crushing processes, this production line not only improves the steel recovery rate, but also reduces the environmental impact of steel slag accumulation, further promoting the development of circular economy and the goals of energy conservation and environmental protection.

Previous: SMP Crusher

Next: SMP Crusher

The steel slag crushing production line responds to the national energy conservation and environmental protection policy and uses equipment such as jaw crushers and cone crushers to efficiently process steel slag and realize resource recycling an

The steel slag crushing production line responds to the national energy conservation and environmental protection policy and uses equipment such as jaw crushers and cone crushers to efficiently process steel slag and realize resource recycling and reuse. It can be used in many fields, has significant economic benefits, reduces environmental pollution, and promotes the development of circular economy.

Abstract generated by the author through intelligent technology

it works

The steel slag crushing production line is in response to the national energy conservation and environmental protection policy. According to the hardness characteristics of steel slag, the equipment is reasonably configured to realize the resource recycling and reuse of steel slag.

Details of steel slag recycling equipment

1. Applicable materials and application fields

Applicable materials: steel slag

Application fields: The processed steel slag can be used in a variety of fields, such as smelting solvents, cement raw materials, construction aggregates, railway ballast, foundation backfill, brick and tile materials, steel slag fertilizers and soil conditioners, etc.

2. Equipment configuration and process flow

Main equipment: vibrating feeder, jaw crusher, hydraulic cone crusher, vibrating screen, belt conveyor, iron remover, etc.

Process flow: The raw materials pass through the vibrating feeder, are classified according to particle size, and then enter the jaw crusher and cone crusher for secondary crushing. During the crushing process, an iron remover is used to extract iron blocks from the steel slag. The crushed materials are screened by the vibrating screen, and the finished products that meet the standards are directly output, while the unqualified materials are returned to the crusher for reprocessing.

3. Economic benefits of steel slag reuse

Steel slag is a solid waste in steel production. After crushing, it can not only recover steel resources, but can also be used in construction materials, road paving, brick manufacturing and other fields, significantly improving economic and environmental benefits. In particular, the recyclable iron content in steel slag can reach 7%-15%. The comprehensive utilization of steel slag has become an important way to realize waste resource utilization.

4. Equipment performance advantages

This production line uses jaw crushers and hydraulic cone crushers, which have the characteristics of high crushing efficiency, low energy consumption, and high degree of automation. In addition, the equipment has excellent wear resistance and low overall operating costs.

5. Technical support and flexible design

Shanmei Company provides customized process solutions and technical support based on customer needs, and makes adjustments based on actual on-site conditions to ensure that steel slag treatment achieves the ideal effect.

6. Environmentally friendly and efficient processing technology

Through advanced iron removal, screening, and crushing processes, this production line not only improves the steel recovery rate, but also reduces the environmental impact of steel slag accumulation, further promoting the development of circular economy and the goals of energy conservation and environmental protection.

Previous: SMP Crusher

Next: SMP Crusher

Introduction to the performance and application of jaw mobile crusher

Introduction to the performance and application of jaw mobile crusher Can metal mine tailings be used as sand and gravel

Can metal mine tailings be used as sand and gravel EPC(O) one-stop general contracting service: from planning to operation, fully responding to sand and gravel challenges

EPC(O) one-stop general contracting service: from planning to operation, fully responding to sand and gravel challenges What are the factors affecting the price of stone factory production equipment?

What are the factors affecting the price of stone factory production equipment? What are the new sand making machines with an output of 500 tons per hour and how much do they cost?

What are the new sand making machines with an output of 500 tons per hour and how much do they cost? Introduction to the performance and application of jaw mobile crusher

Introduction to the performance and application of jaw mobile crusher Can metal mine tailings be used as sand and gravel

Can metal mine tailings be used as sand and gravel EPC(O) one-stop general contracting service: from planning to operation, fully responding to sand and gravel challenges

EPC(O) one-stop general contracting service: from planning to operation, fully responding to sand and gravel challenges What are the factors affecting the price of stone factory production equipment?

What are the factors affecting the price of stone factory production equipment? What are the new sand making machines with an output of 500 tons per hour and how much do they cost?

What are the new sand making machines with an output of 500 tons per hour and how much do they cost?