From coarse crushing to sand making, stone production lines utilize jaw crushers, cone crushers, and sand making machines, forming a highly efficient closed-loop system. Prices range from hundreds of thousands to millions of yuan depending on the confi

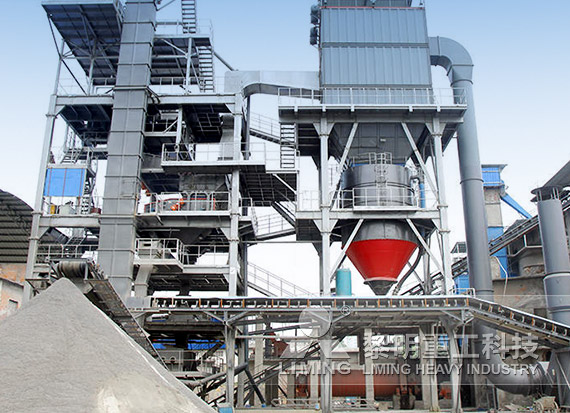

From coarse crushing to sand making, stone production lines utilize jaw crushers, cone crushers, and sand making machines, forming a highly efficient closed-loop system. Prices range from hundreds of thousands to millions of yuan depending on the configuration, meeting diverse production needs.

Common equipment in stone production lines includes jaw crushers, cone crushers, impact crushers, sand making machines, vibrating screens, and conveyors.

a. Crushing: Large quarried stone is first evenly fed from a stockpile by a vibrating feeder into a jaw crusher for coarse crushing. The coarsely crushed stone is then conveyed by a belt conveyor to a cone crusher (or impact crusher) for sizing.

b. Sand Making: The sizing-crushed stone is conveyed by a belt conveyor to a vibrating screen for screening. Those meeting the desired particle size are then fed to a sand making machine for sand making. Those not meeting the desired particle size are returned to the cone crusher (or impact crusher) for secondary sizing. The sizing-crushed stone is then conveyed by a belt conveyor to a vibrating screen for screening, forming a multi-stage closed-loop system.

c. Sand Washing: Finished sand from the sand making machine that meets production particle size requirements is transported to the sand washing machine via a belt conveyor for cleaning.

What is the price of stone production line equipment?

Stone production line equipment comes in a variety of models, with significant price differences. The equipment configurations of the stone quarry crushing production lines also vary, including fixed and mobile types. Therefore, prices vary widely, generally ranging from hundreds of thousands to over a million yuan.

Previous: SMP Crusher

Next: SMP Crusher

From coarse crushing to sand making, stone production lines utilize jaw crushers, cone crushers, and sand making machines, forming a highly efficient closed-loop system. Prices range from hundreds of thousands to millions of yuan depending on the confi

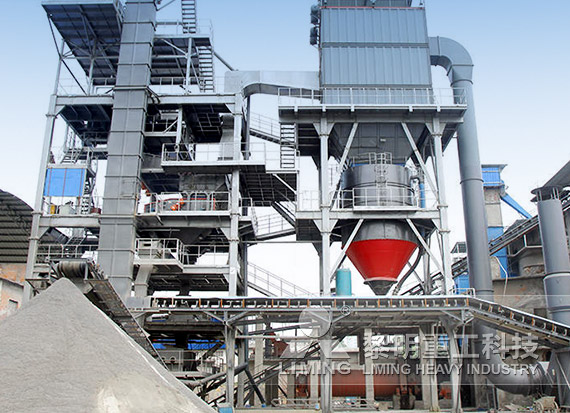

From coarse crushing to sand making, stone production lines utilize jaw crushers, cone crushers, and sand making machines, forming a highly efficient closed-loop system. Prices range from hundreds of thousands to millions of yuan depending on the configuration, meeting diverse production needs.

Common equipment in stone production lines includes jaw crushers, cone crushers, impact crushers, sand making machines, vibrating screens, and conveyors.

a. Crushing: Large quarried stone is first evenly fed from a stockpile by a vibrating feeder into a jaw crusher for coarse crushing. The coarsely crushed stone is then conveyed by a belt conveyor to a cone crusher (or impact crusher) for sizing.

b. Sand Making: The sizing-crushed stone is conveyed by a belt conveyor to a vibrating screen for screening. Those meeting the desired particle size are then fed to a sand making machine for sand making. Those not meeting the desired particle size are returned to the cone crusher (or impact crusher) for secondary sizing. The sizing-crushed stone is then conveyed by a belt conveyor to a vibrating screen for screening, forming a multi-stage closed-loop system.

c. Sand Washing: Finished sand from the sand making machine that meets production particle size requirements is transported to the sand washing machine via a belt conveyor for cleaning.

What is the price of stone production line equipment?

Stone production line equipment comes in a variety of models, with significant price differences. The equipment configurations of the stone quarry crushing production lines also vary, including fixed and mobile types. Therefore, prices vary widely, generally ranging from hundreds of thousands to over a million yuan.

Previous: SMP Crusher

Next: SMP Crusher

What are the equipment for producing stone production line

What are the equipment for producing stone production line Shibangs 500-600 tph limestone crushing and sand making production line: a model of high efficiency and energy saving

Shibangs 500-600 tph limestone crushing and sand making production line: a model of high efficiency and energy saving Large stone crushing equipment

Large stone crushing equipment What are the effects of high temperature environment when the crusher is working

What are the effects of high temperature environment when the crusher is working How to achieve normal production of crusher under high temperature

How to achieve normal production of crusher under high temperature What are the equipment for producing stone production line

What are the equipment for producing stone production line Shibangs 500-600 tph limestone crushing and sand making production line: a model of high efficiency and energy saving

Shibangs 500-600 tph limestone crushing and sand making production line: a model of high efficiency and energy saving Large stone crushing equipment

Large stone crushing equipment What are the effects of high temperature environment when the crusher is working

What are the effects of high temperature environment when the crusher is working How to achieve normal production of crusher under high temperature

How to achieve normal production of crusher under high temperature