As the 1 rare metal, tungsten has a very high melting point and hardness, and is an indispensable strategic resource in modern industry. The wide range of applications of tungsten covers many fields, from the manufacture of filaments to high-strength a

As the 1 rare metal, tungsten has a very high melting point and hardness, and is an indispensable strategic resource in modern industry. The wide range of applications of tungsten covers many fields, from the manufacture of filaments to high-strength alloy tools and aerospace devices. In China, as the world's largest storage of tungsten resources, how to extract and process tungsten ore efficiently is particularly important. This article will introduce tungsten mineral processing equipment and related processes in detail to help you better understand these 1 key links.

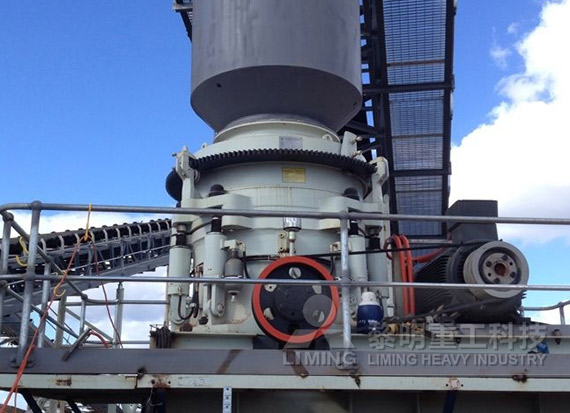

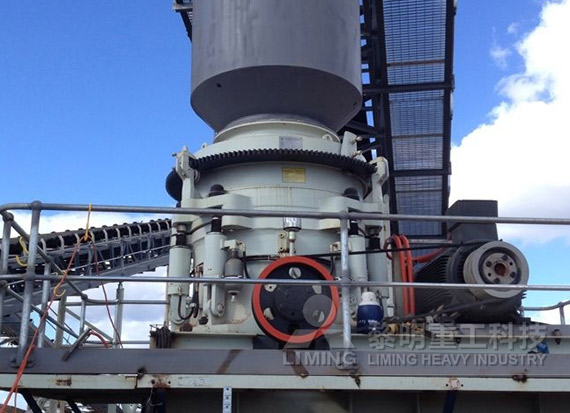

Tungsten ore crushing equipment

Tungsten ore dressing equipment and its role

Tungsten ore dressing production line includes a variety of equipment, and every 1 of equipment plays an important role in the production process. The following are the main devices and their functions:

jaw crusher:

It is mainly used for the primary crushing of tungsten ore to crush large pieces of ore into smaller particles to provide a suitable particle size for subsequent grinding and beneficiation.

Ball Mill:

The crushed tungsten ore is ground to further refine its particle size, which is conducive to the beneficiation process. The ball mill can ensure that the ore particles are uniform, thereby improving the efficiency of mineral processing.

Classifier:

For the classification of ore screening, according to the size of the ore is divided into different grades, for the next step of the beneficiation process to prepare.

magnetic separator and flotation machine:

These two kinds of equipment are the core of tungsten ore beneficiation. Magnetic separators are used to separate magnetic minerals, while flotation machines separate tungsten ore from impurities through the action of chemicals.

thickener and dryer:

The thickener is used to concentrate the pulp and increase the mineral content, while the dryer is used to remove the moisture in the ore and ensure the quality of the ore during smelting.

Tungsten ore beneficiation process

Tungsten ore beneficiation process includes a series of steps, each step has its own special role:

Pre-selection:

Pre-selection of tungsten ore includes washing, desliming and classification. In this 1 stage, the waste rock in the ore is removed by hand selection, photoelectric selection and heavy medium beneficiation, so that the tungsten content of the ore is initially improved.

Rereselect:

These 1 processes are mainly carried out by jigging machines and shakers to separate tungsten minerals from other impurities in the ore. Especially for wolframite, re-election is the main beneficiation method, and the grade of tungsten concentrate can be effectively improved by multi-stage jigging and shaking table re-election.

Flotation:

For complex scheelite, flotation is the key step. By adding appropriate flotation reagents, tungsten minerals are separated from impurities to obtain pure tungsten minerals.

SELECTED AND COMPREHENSIVE RECOVERY:

In the process of selection, the associated valuable metals can also be recovered by means of table floating, magnetic separation and electrical separation. This not only improves the utilization rate of tungsten ore, but also obtains additional products such as tin, molybdenum, and copper.

Challenges and Solutions of Tungsten Mineral Processing

Tungsten ore beneficiation is challenging because of its complex mineral composition and low grade. Scheelite, in particular, often requires complex flotation processes due to its difficult selection. However, through the continuous optimization of mineral processing equipment and process, these problems have been effectively solved. As a leading supplier of mining equipment in the industry, Shibang Group provides a series of efficient and environmentally friendly mineral processing equipment, providing solid technical support for the efficient development of tungsten ore.

Tungsten ore dressing equipment and its process are the key links to ensure the efficient use of tungsten resources. Through scientific and reasonable equipment selection and process design, the beneficiation efficiency and concentrate quality of tungsten ore can be significantly improved. With the continuous progress of technology, the future tungsten ore dressing process will be more intelligent and environmentally friendly, contributing more to the development of tungsten industry in China and the world.

Previous: SMP Crusher

Next: SMP Crusher

As the 1 rare metal, tungsten has a very high melting point and hardness, and is an indispensable strategic resource in modern industry. The wide range of applications of tungsten covers many fields, from the manufacture of filaments to high-strength a

As the 1 rare metal, tungsten has a very high melting point and hardness, and is an indispensable strategic resource in modern industry. The wide range of applications of tungsten covers many fields, from the manufacture of filaments to high-strength alloy tools and aerospace devices. In China, as the world's largest storage of tungsten resources, how to extract and process tungsten ore efficiently is particularly important. This article will introduce tungsten mineral processing equipment and related processes in detail to help you better understand these 1 key links.

Tungsten ore crushing equipment

Tungsten ore dressing equipment and its role

Tungsten ore dressing production line includes a variety of equipment, and every 1 of equipment plays an important role in the production process. The following are the main devices and their functions:

jaw crusher:

It is mainly used for the primary crushing of tungsten ore to crush large pieces of ore into smaller particles to provide a suitable particle size for subsequent grinding and beneficiation.

Ball Mill:

The crushed tungsten ore is ground to further refine its particle size, which is conducive to the beneficiation process. The ball mill can ensure that the ore particles are uniform, thereby improving the efficiency of mineral processing.

Classifier:

For the classification of ore screening, according to the size of the ore is divided into different grades, for the next step of the beneficiation process to prepare.

magnetic separator and flotation machine:

These two kinds of equipment are the core of tungsten ore beneficiation. Magnetic separators are used to separate magnetic minerals, while flotation machines separate tungsten ore from impurities through the action of chemicals.

thickener and dryer:

The thickener is used to concentrate the pulp and increase the mineral content, while the dryer is used to remove the moisture in the ore and ensure the quality of the ore during smelting.

Tungsten ore beneficiation process

Tungsten ore beneficiation process includes a series of steps, each step has its own special role:

Pre-selection:

Pre-selection of tungsten ore includes washing, desliming and classification. In this 1 stage, the waste rock in the ore is removed by hand selection, photoelectric selection and heavy medium beneficiation, so that the tungsten content of the ore is initially improved.

Rereselect:

These 1 processes are mainly carried out by jigging machines and shakers to separate tungsten minerals from other impurities in the ore. Especially for wolframite, re-election is the main beneficiation method, and the grade of tungsten concentrate can be effectively improved by multi-stage jigging and shaking table re-election.

Flotation:

For complex scheelite, flotation is the key step. By adding appropriate flotation reagents, tungsten minerals are separated from impurities to obtain pure tungsten minerals.

SELECTED AND COMPREHENSIVE RECOVERY:

In the process of selection, the associated valuable metals can also be recovered by means of table floating, magnetic separation and electrical separation. This not only improves the utilization rate of tungsten ore, but also obtains additional products such as tin, molybdenum, and copper.

Challenges and Solutions of Tungsten Mineral Processing

Tungsten ore beneficiation is challenging because of its complex mineral composition and low grade. Scheelite, in particular, often requires complex flotation processes due to its difficult selection. However, through the continuous optimization of mineral processing equipment and process, these problems have been effectively solved. As a leading supplier of mining equipment in the industry, Shibang Group provides a series of efficient and environmentally friendly mineral processing equipment, providing solid technical support for the efficient development of tungsten ore.

Tungsten ore dressing equipment and its process are the key links to ensure the efficient use of tungsten resources. Through scientific and reasonable equipment selection and process design, the beneficiation efficiency and concentrate quality of tungsten ore can be significantly improved. With the continuous progress of technology, the future tungsten ore dressing process will be more intelligent and environmentally friendly, contributing more to the development of tungsten industry in China and the world.

Previous: SMP Crusher

Next: SMP Crusher

How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation 69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment

69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment Selection Guide and Price Analysis of Basalt Stone Crusher with a Nissan of 20,000 Tons

Selection Guide and Price Analysis of Basalt Stone Crusher with a Nissan of 20,000 Tons How was the sand crushing project with an hourly output of 1000 tons of basalt built?

How was the sand crushing project with an hourly output of 1000 tons of basalt built? Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs

Cone crusher: efficient medium and fine crushing solution, professional response to ore processing needs How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation 69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment

69 Jaw Crusher How to Choose 2 Crusher and Supporting Equipment Selection Guide and Price Analysis of Basalt Stone Crusher with a Nissan of 20,000 Tons

Selection Guide and Price Analysis of Basalt Stone Crusher with a Nissan of 20,000 Tons