Coal-based activated carbon is made of coal with good quality as raw material, which is generally made of powdered raw material and binder by kneading, extrusion molding, carbonization and activation. It has the characteristics of good adsorption perfo

Coal-based activated carbon is made of coal with good quality as raw material, which is generally made of powdered raw material and binder by kneading, extrusion molding, carbonization and activation. It has the characteristics of good adsorption performance, high mechanical strength, easy repeated regeneration and low cost. It is used in toxic gas purification, waste gas treatment, industrial and domestic water purification treatment, solvent recovery and so on. High quality pulverized coal is the guarantee of producing high quality activated carbon.

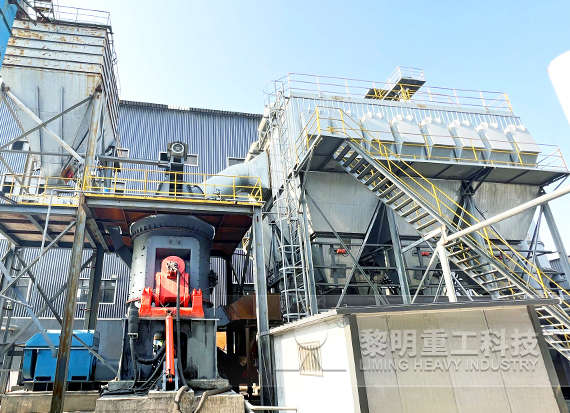

Processing materials for semi-coke, bituminous coal, finished product fineness requirements 325 mesh D85, customers in the research found that Liming Heavy Mill in the field of activated carbon milling market share is very high, and many achieved performance breakthroughs, and ultimately decided to purchase LM1900M as the host equipment, and Liming Heavy Industry designed the entire production line.

The customer is a large domestic activated carbon manufacturer. The activated carbon powder is used as the desulfurization and denitrification adsorbent of the steel mill. The project scale is large and the equipment capacity is high. Production line configuration : coal feeder + drying system + LM1900M vertical mill + explosion-proof pulse collector + fan + conveying equipment + finished warehouse.

Previous: SMP Crusher

Next: SMP Crusher

Coal-based activated carbon is made of coal with good quality as raw material, which is generally made of powdered raw material and binder by kneading, extrusion molding, carbonization and activation. It has the characteristics of good adsorption perfo

Coal-based activated carbon is made of coal with good quality as raw material, which is generally made of powdered raw material and binder by kneading, extrusion molding, carbonization and activation. It has the characteristics of good adsorption performance, high mechanical strength, easy repeated regeneration and low cost. It is used in toxic gas purification, waste gas treatment, industrial and domestic water purification treatment, solvent recovery and so on. High quality pulverized coal is the guarantee of producing high quality activated carbon.

Processing materials for semi-coke, bituminous coal, finished product fineness requirements 325 mesh D85, customers in the research found that Liming Heavy Mill in the field of activated carbon milling market share is very high, and many achieved performance breakthroughs, and ultimately decided to purchase LM1900M as the host equipment, and Liming Heavy Industry designed the entire production line.

The customer is a large domestic activated carbon manufacturer. The activated carbon powder is used as the desulfurization and denitrification adsorbent of the steel mill. The project scale is large and the equipment capacity is high. Production line configuration : coal feeder + drying system + LM1900M vertical mill + explosion-proof pulse collector + fan + conveying equipment + finished warehouse.

Previous: SMP Crusher

Next: SMP Crusher