Common types of crushing equipment for sand and gravel production include jaw crushers, impact crushers, cone crushers, and impact crushers.To learn more about sand and gravel crushing equipment, click here for an inquiry.

Common types of crushing equipment for sand and gravel production include jaw crushers, impact crushers, cone crushers, and impact crushers.

To learn more about sand and gravel crushing equipment, click here for an inquiry.

Jaw Crusher

The jaw crusher is specifically designed to crush hard rock, ores, and a variety of other materials. Its core mechanism utilizes the powerful squeezing force between its two jaws to effectively break up large pieces of material, laying the foundation for subsequent fine crushing. As the preferred equipment for the stone crushing process, it not only handles a variety of complex materials but also holds a key position in the industry for its efficient initial crushing capabilities, ensuring efficient and smooth production lines.

Impact Crusher

The impact crusher is designed for medium and fine crushing, excelling at handling materials with a hardness below medium. Its operating principle relies on the impact of high-speed hammers, resulting in outstanding efficiency and stable performance. In the middle and later stages of the stone crushing process, the impact crusher demonstrates excellent fine crushing capabilities, providing strong support for the production of high-quality crushed stone products.

Cone Crusher

Cone crushers specialize in medium and fine crushing, particularly for materials with a medium hardness or below. They utilize the powerful squeezing force generated by the crushing cone to efficiently crush materials. Known for their excellent product particle size uniformity and ability to produce an ideal particle size distribution, these crushers are ideal for applications requiring stringent crushed stone particle size requirements, such as construction aggregates and road paving materials, ensuring the final product meets high quality standards.

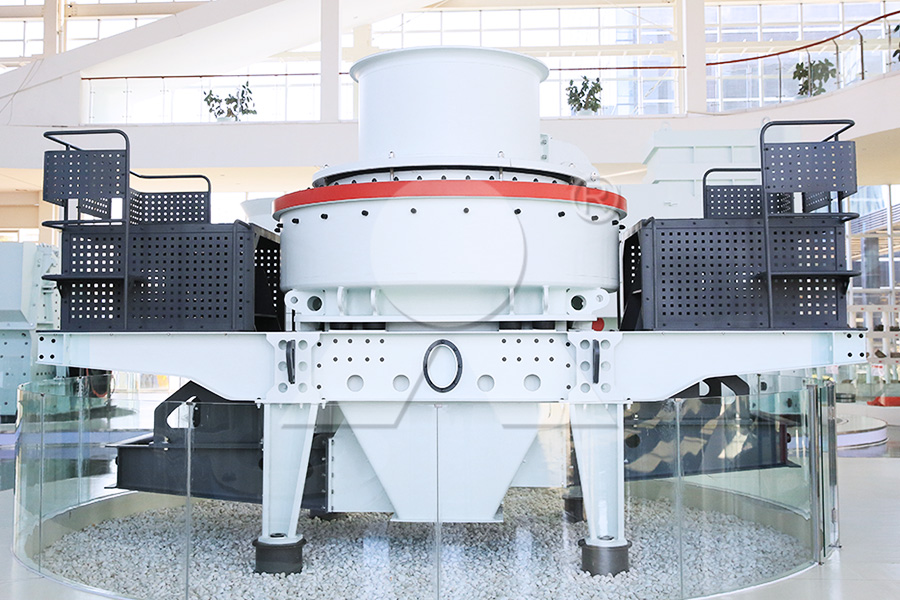

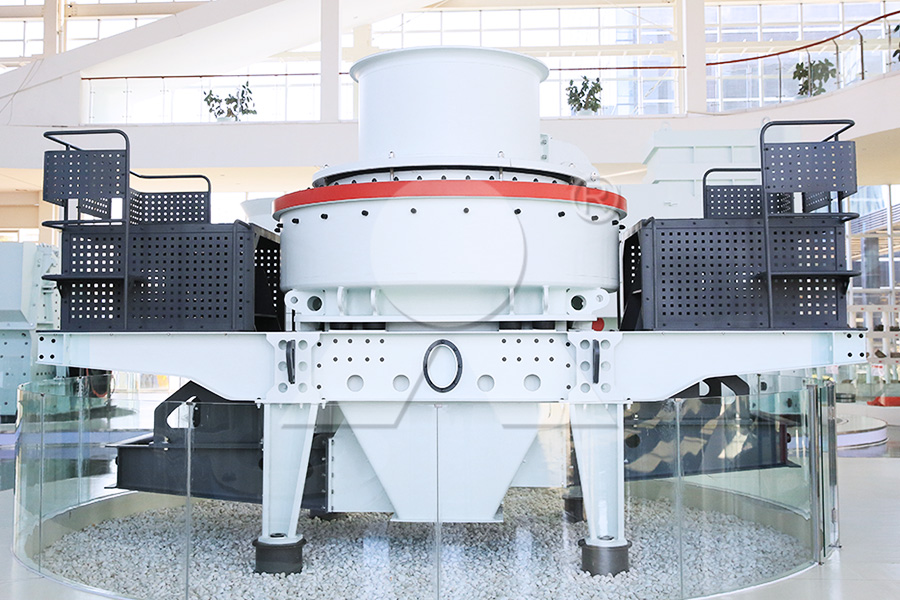

Impact Crusher

Impact crushers are primarily used for medium and fine crushing, particularly for brittle materials. They operate by using high-speed rotating hammers to impact and crush the material. Impact crushers offer strong crushing capacity and high efficiency, making them ideal for fine crushing in stone processing.

How much does stone crushing equipment cost?

Prices for the above-mentioned stone crushing equipment vary, influenced by numerous factors, including the type and model of equipment. Furthermore, with numerous manufacturers on the market, product variations vary widely, typically ranging from hundreds of thousands to several hundred thousand yuan, or even millions of yuan.

Previous: SMP Crusher

Next: SMP Crusher

Common types of crushing equipment for sand and gravel production include jaw crushers, impact crushers, cone crushers, and impact crushers.To learn more about sand and gravel crushing equipment, click here for an inquiry.

Common types of crushing equipment for sand and gravel production include jaw crushers, impact crushers, cone crushers, and impact crushers.

To learn more about sand and gravel crushing equipment, click here for an inquiry.

Jaw Crusher

The jaw crusher is specifically designed to crush hard rock, ores, and a variety of other materials. Its core mechanism utilizes the powerful squeezing force between its two jaws to effectively break up large pieces of material, laying the foundation for subsequent fine crushing. As the preferred equipment for the stone crushing process, it not only handles a variety of complex materials but also holds a key position in the industry for its efficient initial crushing capabilities, ensuring efficient and smooth production lines.

Impact Crusher

The impact crusher is designed for medium and fine crushing, excelling at handling materials with a hardness below medium. Its operating principle relies on the impact of high-speed hammers, resulting in outstanding efficiency and stable performance. In the middle and later stages of the stone crushing process, the impact crusher demonstrates excellent fine crushing capabilities, providing strong support for the production of high-quality crushed stone products.

Cone Crusher

Cone crushers specialize in medium and fine crushing, particularly for materials with a medium hardness or below. They utilize the powerful squeezing force generated by the crushing cone to efficiently crush materials. Known for their excellent product particle size uniformity and ability to produce an ideal particle size distribution, these crushers are ideal for applications requiring stringent crushed stone particle size requirements, such as construction aggregates and road paving materials, ensuring the final product meets high quality standards.

Impact Crusher

Impact crushers are primarily used for medium and fine crushing, particularly for brittle materials. They operate by using high-speed rotating hammers to impact and crush the material. Impact crushers offer strong crushing capacity and high efficiency, making them ideal for fine crushing in stone processing.

How much does stone crushing equipment cost?

Prices for the above-mentioned stone crushing equipment vary, influenced by numerous factors, including the type and model of equipment. Furthermore, with numerous manufacturers on the market, product variations vary widely, typically ranging from hundreds of thousands to several hundred thousand yuan, or even millions of yuan.

Previous: SMP Crusher

Next: SMP Crusher

What are the models of 200 tons per hour river pebble sand making machine?

What are the models of 200 tons per hour river pebble sand making machine? What are the advantages of mobile crushing station equipment

What are the advantages of mobile crushing station equipment What are the mobile stone crusher equipment and how much does it cost?

What are the mobile stone crusher equipment and how much does it cost? New sand making equipment type, how much does it cost per set

New sand making equipment type, how much does it cost per set Design of sand and gravel aggregate production line process | Soft rock sand making and hard rock sand making

Design of sand and gravel aggregate production line process | Soft rock sand making and hard rock sand making What are the models of 200 tons per hour river pebble sand making machine?

What are the models of 200 tons per hour river pebble sand making machine? What are the advantages of mobile crushing station equipment

What are the advantages of mobile crushing station equipment What are the mobile stone crusher equipment and how much does it cost?

What are the mobile stone crusher equipment and how much does it cost? New sand making equipment type, how much does it cost per set

New sand making equipment type, how much does it cost per set Design of sand and gravel aggregate production line process | Soft rock sand making and hard rock sand making

Design of sand and gravel aggregate production line process | Soft rock sand making and hard rock sand making