What are the types of stone crushing equipment? How much does it cost?A set of stone crushing equipment mainly includes the following types:1. Jaw crusher (for primary crushing of materials)The jaw crusher crushes boulders with str

What are the types of stone crushing equipment? How much does it cost?

A set of stone crushing equipment mainly includes the following types:

1. Jaw crusher (for primary crushing of materials)

The jaw crusher crushes boulders with strong crushing force and becomes the

key equipment for primary crushing. Its high crushing ratio and capacity ensure

the smooth and efficient first process of the production line. Capacity,

efficiency and stability are its core considerations, which directly affect the

overall operation effect. Therefore, the selection should be cautious to ensure

the stable operation of the production line.

2. Cone crusher (processing materials with higher hardness)

The cone crusher has a simple structure, excellent wear resistance, stable

operation and low failure rate. Its laminated crushing technology is matched

with high wear-resistant materials, and the advanced hydraulic protection system

is specially designed for hard material processing, ensuring efficient crushing

and protecting equipment at the same time. It is the preferred equipment for

hard rock processing.

3. Impact crusher (processing medium and brittle materials)

The impact crusher is the preferred equipment for secondary crushing, which

uses the principle of high-speed impact to refine materials. Through continuous

and repeated impact, the material is gradually broken to the required particle

size. The output particles are of excellent shape, mostly in the shape of cubes,

effectively reducing needle-like particles and ensuring high-quality finished

products.

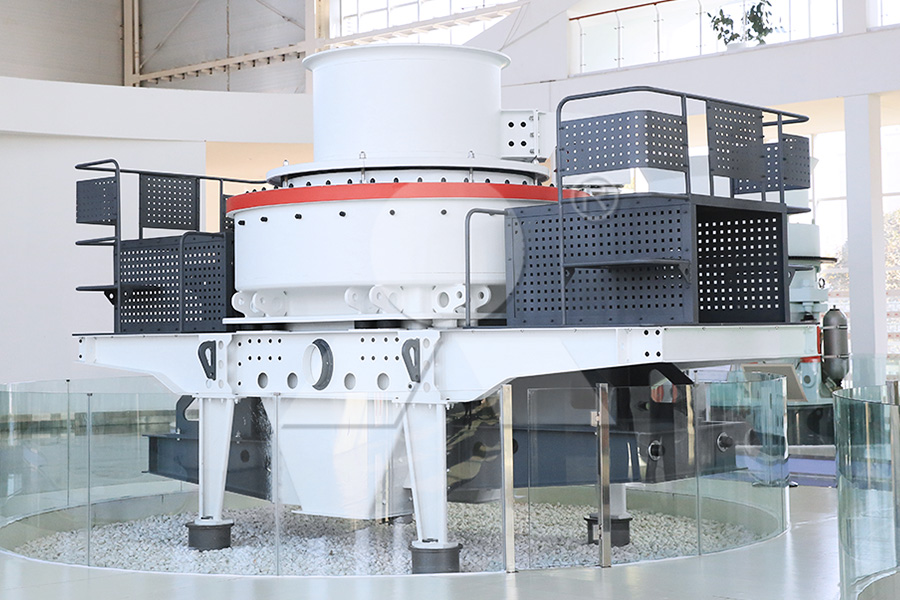

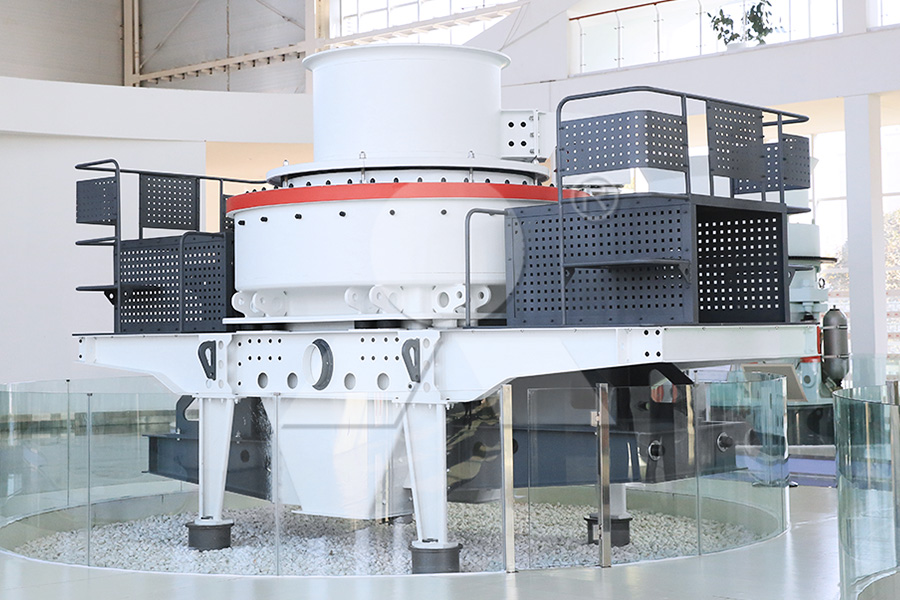

4. Impact crusher (used for material shaping and sand making)

The sand making machine can beat the material into sand of different

specifications such as 0-5mm, and is located in the second half of the entire

production line. Common sand making machines are VSI6X sand making machine,

VSI5X sand making machine, and VSI sand making machine, which have the dual

functions of sand making and shaping. The material produced has good particle

shape, uniform particle size, and reasonable grading.

How much does a stone crushing equipment cost?

Different production needs and different production conditions have different

configuration plans for stone crushing equipment, and the quotation is naturally

different, generally ranging from hundreds of thousands to millions.

Previous: SMP Crusher

Next: SMP Crusher

What are the types of stone crushing equipment? How much does it cost?A set of stone crushing equipment mainly includes the following types:1. Jaw crusher (for primary crushing of materials)The jaw crusher crushes boulders with str

What are the types of stone crushing equipment? How much does it cost?

A set of stone crushing equipment mainly includes the following types:

1. Jaw crusher (for primary crushing of materials)

The jaw crusher crushes boulders with strong crushing force and becomes the

key equipment for primary crushing. Its high crushing ratio and capacity ensure

the smooth and efficient first process of the production line. Capacity,

efficiency and stability are its core considerations, which directly affect the

overall operation effect. Therefore, the selection should be cautious to ensure

the stable operation of the production line.

2. Cone crusher (processing materials with higher hardness)

The cone crusher has a simple structure, excellent wear resistance, stable

operation and low failure rate. Its laminated crushing technology is matched

with high wear-resistant materials, and the advanced hydraulic protection system

is specially designed for hard material processing, ensuring efficient crushing

and protecting equipment at the same time. It is the preferred equipment for

hard rock processing.

3. Impact crusher (processing medium and brittle materials)

The impact crusher is the preferred equipment for secondary crushing, which

uses the principle of high-speed impact to refine materials. Through continuous

and repeated impact, the material is gradually broken to the required particle

size. The output particles are of excellent shape, mostly in the shape of cubes,

effectively reducing needle-like particles and ensuring high-quality finished

products.

4. Impact crusher (used for material shaping and sand making)

The sand making machine can beat the material into sand of different

specifications such as 0-5mm, and is located in the second half of the entire

production line. Common sand making machines are VSI6X sand making machine,

VSI5X sand making machine, and VSI sand making machine, which have the dual

functions of sand making and shaping. The material produced has good particle

shape, uniform particle size, and reasonable grading.

How much does a stone crushing equipment cost?

Different production needs and different production conditions have different

configuration plans for stone crushing equipment, and the quotation is naturally

different, generally ranging from hundreds of thousands to millions.

Previous: SMP Crusher

Next: SMP Crusher

How to configure a pebble sand production line? How much does a pebble sand production line cost?

How to configure a pebble sand production line? How much does a pebble sand production line cost? What are the complete set of sand and gravel aggregate production line equipment?

What are the complete set of sand and gravel aggregate production line equipment? How to choose crushing equipment for large-scale crushing production lines in mines

How to choose crushing equipment for large-scale crushing production lines in mines What is the complete set of sand and gravel aggregate production line equipment? How much does it cost?

What is the complete set of sand and gravel aggregate production line equipment? How much does it cost? How to control dust and noise pollution in the new sand and gravel production line of stone quarry

How to control dust and noise pollution in the new sand and gravel production line of stone quarry How to configure a pebble sand production line? How much does a pebble sand production line cost?

How to configure a pebble sand production line? How much does a pebble sand production line cost? What are the complete set of sand and gravel aggregate production line equipment?

What are the complete set of sand and gravel aggregate production line equipment? How to choose crushing equipment for large-scale crushing production lines in mines

How to choose crushing equipment for large-scale crushing production lines in mines What is the complete set of sand and gravel aggregate production line equipment? How much does it cost?

What is the complete set of sand and gravel aggregate production line equipment? How much does it cost? How to control dust and noise pollution in the new sand and gravel production line of stone quarry

How to control dust and noise pollution in the new sand and gravel production line of stone quarry