Lapis lazuli, as a common building material, is widely used in road construction, house building and landscape projects. It is crucial to crush lapis lazuli to meet the needs of different engineering projects. In this article, we will discuss the

Lapis lazuli, as a common building material, is widely used in road construction, house building and landscape projects. It is crucial to crush lapis lazuli to meet the needs of different engineering projects. In this article, we will discuss the quality of lapis lazuli crushing stone and how to set up a high-quality lapis lazuli crushing production line required equipment.

What about the quality of lapis lazuli crushing stone?

Lapis lazuli is usually a hard and wear-resistant rock with high compressive strength and durability. Therefore, the stones crushed from lapis lazuli usually have the following characteristics:

High compressive strength:

Stones obtained from crushing lapis lazuli usually have high compressive strength, which is suitable for a variety of construction and foundation works.

Durability:

Lapis lazuli crushed stones have high durability and are not easily eroded and damaged by environmental factors.

Hardness:

The stones are usually hard and resistant to wear and tear, making them suitable for road surfacing and can provide long-term stability.

Consistent colour:

Crushed lapis lazuli stones usually have a uniform colour that is aesthetically pleasing and suitable for landscaping projects.

Overall, crushed lapis lazuli results in high quality stones that are suitable for use in a variety of construction and engineering projects. However, in order to obtain high quality crushed stone, it is necessary to use appropriate crushing equipment and suitable production line.

Equipment required to set up a lapis lazuli crushing line

1 Jaw Crusher_Rough Crushing

Jaw crusher is the most common crusher in stone crushing production line, it is the coarse crushing treatment for all kinds of stones, adopting mature production technology design, making it has good product characteristics, and it is the primary equipment of mining crushing production line. It can produce 1-2200 tonnes per hour of stone with a grain size of 10-400mm.

2 Cone Crusher_Intermediate Crushing

Many stone raw materials after the initial coarse crushing treatment, but also need to carry out the middle and fine crushing processing shaping, this link will use the cone crusher. The machine can produce 12-2181 tonnes of stone with a granularity of 3-400mm per hour, mostly used in large sand and gravel plants, mainly using the extrusion between the materials to complete the crushing, less damage to wearing parts, and the use of high wear-resistant materials, equipment, wear resistance is very strong, it is very suitable for dealing with bluestone.

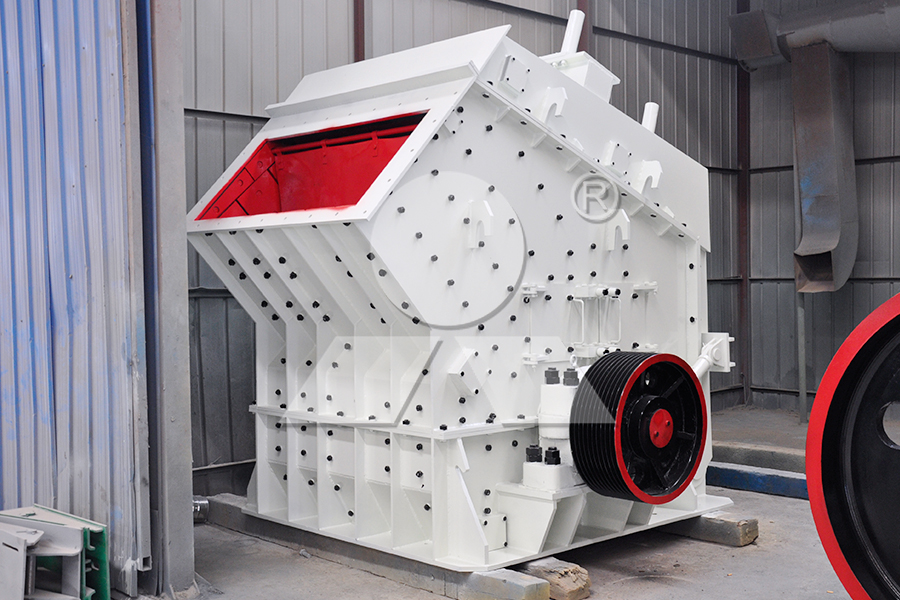

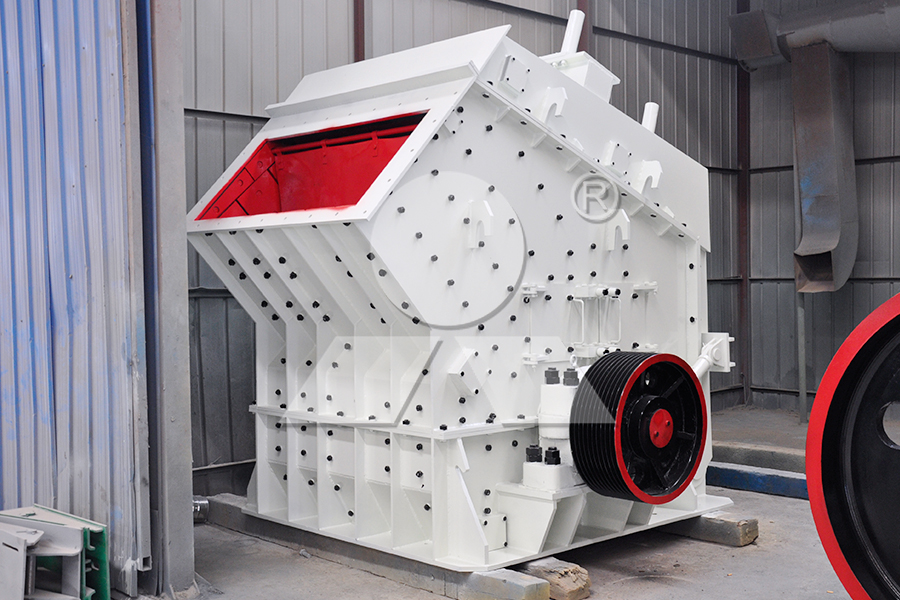

3 Impact Crusher (Sand Making Machine)_Fine Crushing

Impact crusher, also known as sand making machine, is the key equipment used in stone plant for fine crushing and shaping of stone materials, the sand produced is of uniform quality, well-graded, beautiful particle size, less overcrushed, which can meet the high standard requirements of the field of materials. It can produce 12-650 tonnes of sand per hour. The sand making machine is a new type of intelligent equipment, easy and convenient to operate, the equipment meets the environmental standards, stable and reliable operation.

How much does a set of lapis lazuli crushing production line cost?

We all know that the machinery and equipment for crushing bluestone is divided into many kinds, the structure and manufacture of each kind of equipment are different, and the value brought to the user is also different, the price must be very different, and affect the price of the equipment and its output, 100 tonnes per hour and 1,000 tonnes per hour price difference is still relatively large, the important thing is to choose the right equipment.

In the choice of machinery for crushing lapis lazuli, both to meet the production needs of enterprises, but also to save production input costs, if you need to buy machinery and equipment for crushing lapis lazuli, you can browse through the online you can browse our web page, there are detailed pictures of the equipment, parameters, performance, production site cases, feel the right words you can click on the consulting online customer service to learn more about the details, you can also come to the factory to visit, personally verify the quality and performance of the equipment. You can also visit our factory to personally verify the quality and performance of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

Lapis lazuli, as a common building material, is widely used in road construction, house building and landscape projects. It is crucial to crush lapis lazuli to meet the needs of different engineering projects. In this article, we will discuss the

Lapis lazuli, as a common building material, is widely used in road construction, house building and landscape projects. It is crucial to crush lapis lazuli to meet the needs of different engineering projects. In this article, we will discuss the quality of lapis lazuli crushing stone and how to set up a high-quality lapis lazuli crushing production line required equipment.

What about the quality of lapis lazuli crushing stone?

Lapis lazuli is usually a hard and wear-resistant rock with high compressive strength and durability. Therefore, the stones crushed from lapis lazuli usually have the following characteristics:

High compressive strength:

Stones obtained from crushing lapis lazuli usually have high compressive strength, which is suitable for a variety of construction and foundation works.

Durability:

Lapis lazuli crushed stones have high durability and are not easily eroded and damaged by environmental factors.

Hardness:

The stones are usually hard and resistant to wear and tear, making them suitable for road surfacing and can provide long-term stability.

Consistent colour:

Crushed lapis lazuli stones usually have a uniform colour that is aesthetically pleasing and suitable for landscaping projects.

Overall, crushed lapis lazuli results in high quality stones that are suitable for use in a variety of construction and engineering projects. However, in order to obtain high quality crushed stone, it is necessary to use appropriate crushing equipment and suitable production line.

Equipment required to set up a lapis lazuli crushing line

1 Jaw Crusher_Rough Crushing

Jaw crusher is the most common crusher in stone crushing production line, it is the coarse crushing treatment for all kinds of stones, adopting mature production technology design, making it has good product characteristics, and it is the primary equipment of mining crushing production line. It can produce 1-2200 tonnes per hour of stone with a grain size of 10-400mm.

2 Cone Crusher_Intermediate Crushing

Many stone raw materials after the initial coarse crushing treatment, but also need to carry out the middle and fine crushing processing shaping, this link will use the cone crusher. The machine can produce 12-2181 tonnes of stone with a granularity of 3-400mm per hour, mostly used in large sand and gravel plants, mainly using the extrusion between the materials to complete the crushing, less damage to wearing parts, and the use of high wear-resistant materials, equipment, wear resistance is very strong, it is very suitable for dealing with bluestone.

3 Impact Crusher (Sand Making Machine)_Fine Crushing

Impact crusher, also known as sand making machine, is the key equipment used in stone plant for fine crushing and shaping of stone materials, the sand produced is of uniform quality, well-graded, beautiful particle size, less overcrushed, which can meet the high standard requirements of the field of materials. It can produce 12-650 tonnes of sand per hour. The sand making machine is a new type of intelligent equipment, easy and convenient to operate, the equipment meets the environmental standards, stable and reliable operation.

How much does a set of lapis lazuli crushing production line cost?

We all know that the machinery and equipment for crushing bluestone is divided into many kinds, the structure and manufacture of each kind of equipment are different, and the value brought to the user is also different, the price must be very different, and affect the price of the equipment and its output, 100 tonnes per hour and 1,000 tonnes per hour price difference is still relatively large, the important thing is to choose the right equipment.

In the choice of machinery for crushing lapis lazuli, both to meet the production needs of enterprises, but also to save production input costs, if you need to buy machinery and equipment for crushing lapis lazuli, you can browse through the online you can browse our web page, there are detailed pictures of the equipment, parameters, performance, production site cases, feel the right words you can click on the consulting online customer service to learn more about the details, you can also come to the factory to visit, personally verify the quality and performance of the equipment. You can also visit our factory to personally verify the quality and performance of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

Iron ore crusher machine and price

Iron ore crusher machine and price Machine for crushing granite granite crushing line programme

Machine for crushing granite granite crushing line programme How many tonnes of sand can be washed in a day by sand washing machine One set down price

How many tonnes of sand can be washed in a day by sand washing machine One set down price Impact sand making machine equipment production line site

Impact sand making machine equipment production line site 69 Jaw crusher discharge size can be controlled within 50mm?

69 Jaw crusher discharge size can be controlled within 50mm? Iron ore crusher machine and price

Iron ore crusher machine and price Machine for crushing granite granite crushing line programme

Machine for crushing granite granite crushing line programme How many tonnes of sand can be washed in a day by sand washing machine One set down price

How many tonnes of sand can be washed in a day by sand washing machine One set down price Impact sand making machine equipment production line site

Impact sand making machine equipment production line site 69 Jaw crusher discharge size can be controlled within 50mm?

69 Jaw crusher discharge size can be controlled within 50mm?