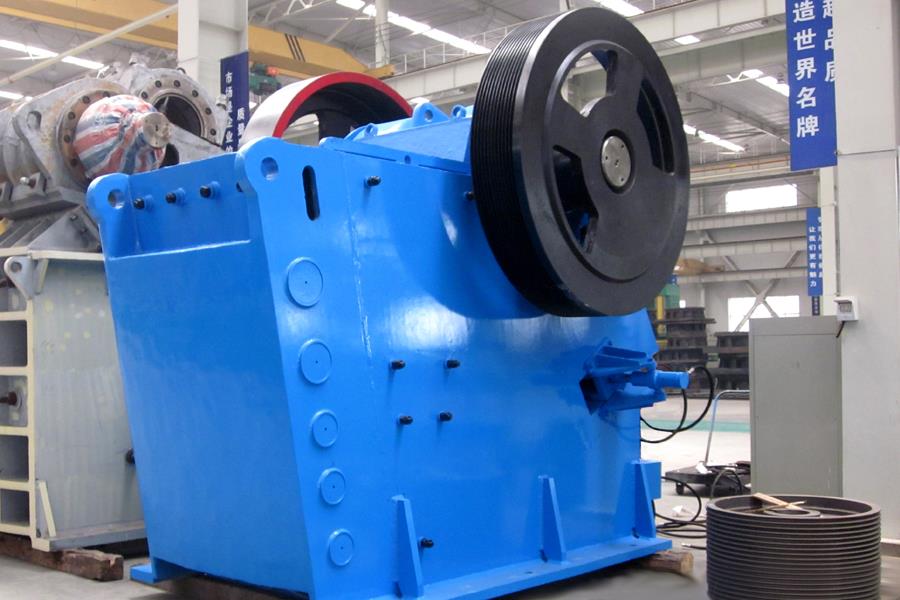

Green mine, intelligent controlCrushing materials:GraniteEquipment configuration:2 JC series jaw crushers, 2 DHS series feeders, 4 GPY series single-cylinder cone crushers, 2 HPY series mu

Green mine, intelligent control

Crushing materials:

Granite

Equipment configuration:

2 JC series jaw crushers, 2 DHS series feeders, 4 GPY series single-cylinder cone crushers, 2 HPY series multi-cylinder cone crushers, 16 YKR series vibrating screens

Material particle size:

Project capacity: 2000t/h sand and gravel aggregates

Process advantage description:

Production line features:

The production line adopts the design concept of green mines and intelligent mines. The overall design makes full use of the terrain advantages, the process design is simple, and the layout is compact and reasonable. The "jaw crusher + cone + cone" three-stage one-closed circuit crushing process is adopted, which can be used in one line. It can process high-calcium stone and produce sand and gravel aggregates. Compared with the impact crushing process, the 40-80mm finished product rate is higher, the operating cost is lower, and the production line is more stable and reliable; each workshop is modularly designed to improve efficiency; centralized layout reduces the investment cost of each workshop. Dust removal system, atomization spray system, and intelligent control system are all available, fully meeting the design requirements.

Previous: SMP Crusher

Next: SMP Crusher

Green mine, intelligent controlCrushing materials:GraniteEquipment configuration:2 JC series jaw crushers, 2 DHS series feeders, 4 GPY series single-cylinder cone crushers, 2 HPY series mu

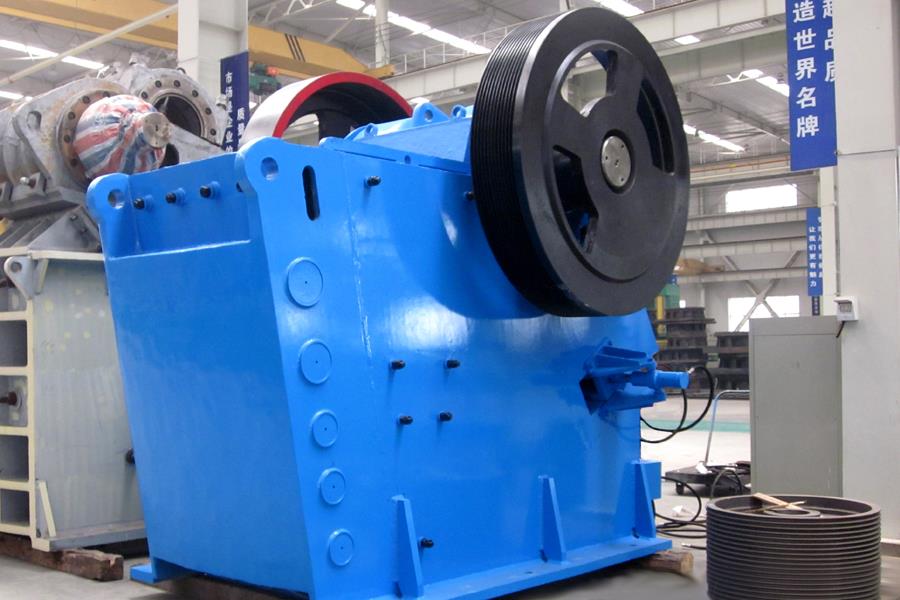

Green mine, intelligent control

Crushing materials:

Granite

Equipment configuration:

2 JC series jaw crushers, 2 DHS series feeders, 4 GPY series single-cylinder cone crushers, 2 HPY series multi-cylinder cone crushers, 16 YKR series vibrating screens

Material particle size:

Project capacity: 2000t/h sand and gravel aggregates

Process advantage description:

Production line features:

The production line adopts the design concept of green mines and intelligent mines. The overall design makes full use of the terrain advantages, the process design is simple, and the layout is compact and reasonable. The "jaw crusher + cone + cone" three-stage one-closed circuit crushing process is adopted, which can be used in one line. It can process high-calcium stone and produce sand and gravel aggregates. Compared with the impact crushing process, the 40-80mm finished product rate is higher, the operating cost is lower, and the production line is more stable and reliable; each workshop is modularly designed to improve efficiency; centralized layout reduces the investment cost of each workshop. Dust removal system, atomization spray system, and intelligent control system are all available, fully meeting the design requirements.

Previous: SMP Crusher

Next: SMP Crusher

Shanxi Jincheng 600tph limestone production line

Shanxi Jincheng 600tph limestone production line Yunnan 2000 tons construction sand and gravel aggregate production line

Yunnan 2000 tons construction sand and gravel aggregate production line Cameroon 200 tons per hour dam sand and gravel aggregate processing production line

Cameroon 200 tons per hour dam sand and gravel aggregate processing production line Tibet 200 tons per hour construction sand and gravel aggregate production line

Tibet 200 tons per hour construction sand and gravel aggregate production line Tangshan 800 tons per hour construction sand and gravel aggregate production line

Tangshan 800 tons per hour construction sand and gravel aggregate production line Shanxi Jincheng 600tph limestone production line

Shanxi Jincheng 600tph limestone production line Yunnan 2000 tons construction sand and gravel aggregate production line

Yunnan 2000 tons construction sand and gravel aggregate production line Cameroon 200 tons per hour dam sand and gravel aggregate processing production line

Cameroon 200 tons per hour dam sand and gravel aggregate processing production line Tibet 200 tons per hour construction sand and gravel aggregate production line

Tibet 200 tons per hour construction sand and gravel aggregate production line Tangshan 800 tons per hour construction sand and gravel aggregate production line

Tangshan 800 tons per hour construction sand and gravel aggregate production line