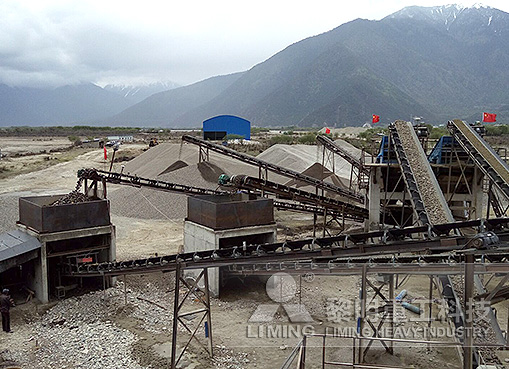

The unit modular structural parts installation method is adopted.Tibet's 200 tons per hour construction sand and gravel aggregate production line (sand and gravel crushing and processing system) is located in the Tibetan plateau.

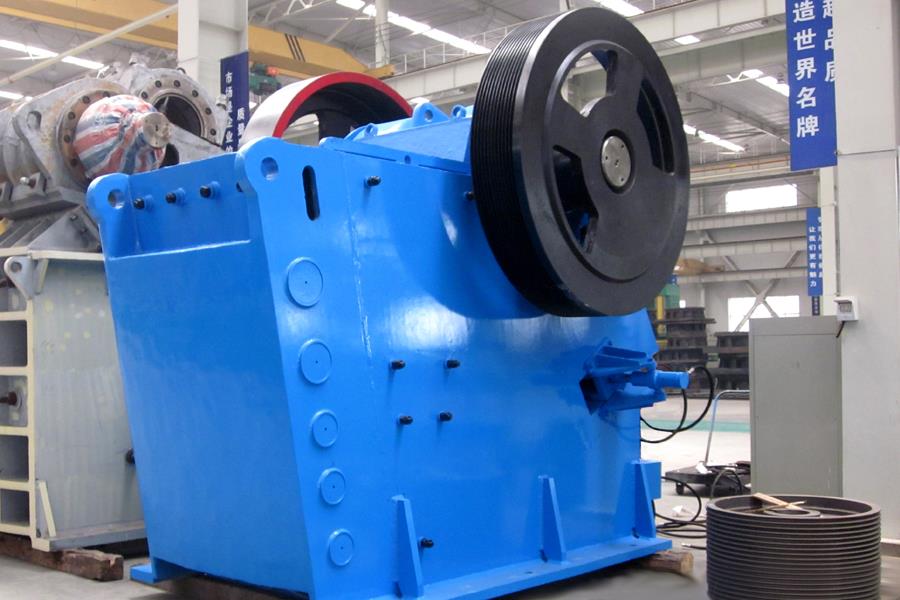

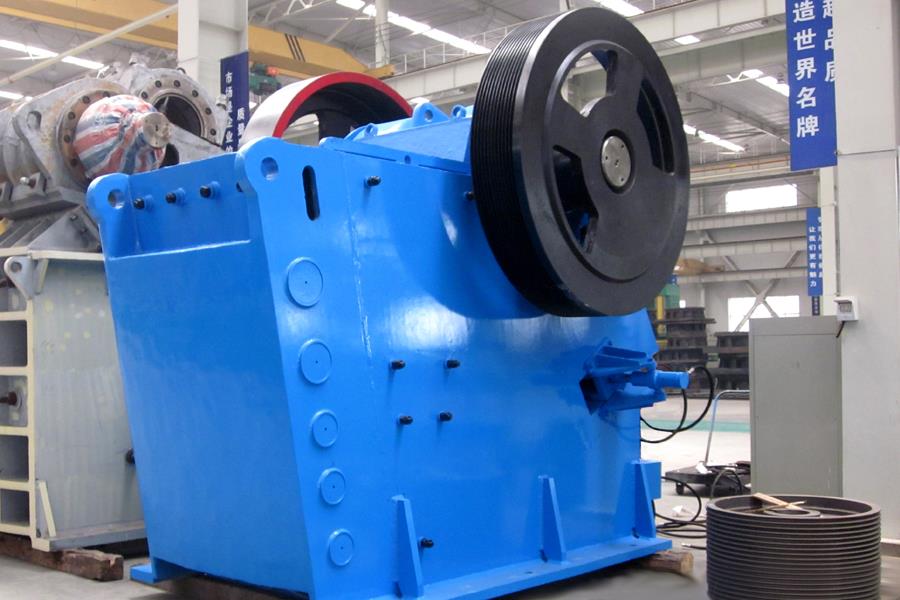

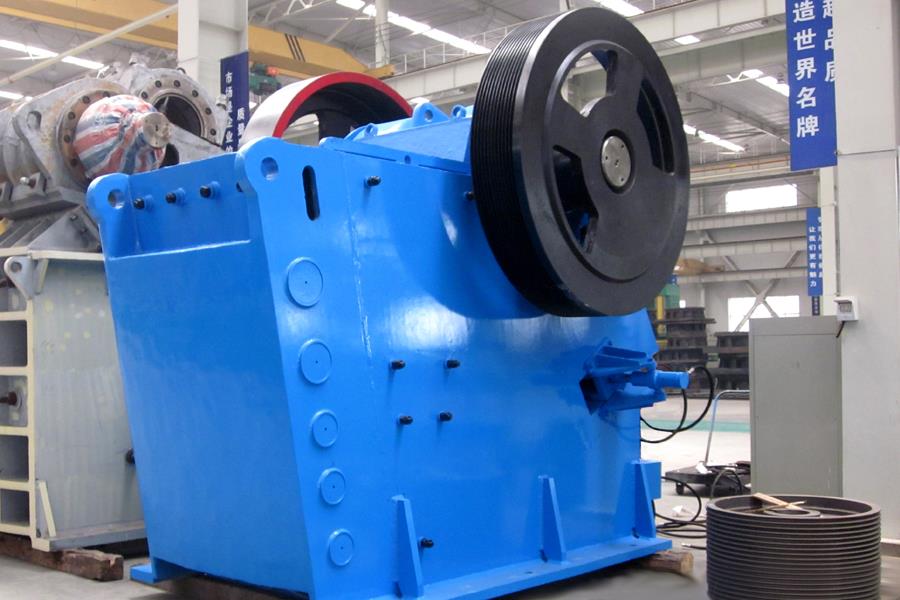

The unit modular structural parts installation method is adopted.

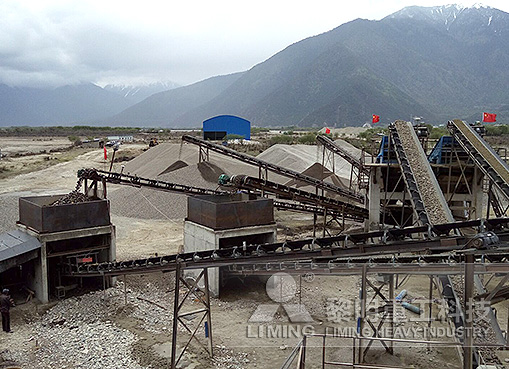

Tibet's 200 tons per hour construction sand and gravel aggregate production line (sand and gravel crushing and processing system) is located in the Tibetan plateau. The system mainly produces construction sand and gravel aggregates. The system is implemented by our company for process design, equipment manufacturing, foundation construction, system installation and commissioning, training, and delivery and operation. In order to improve the system installation efficiency and save investment costs, the system's related equipment adopts the unit modular structural parts installation method. Since the source of the project is natural gravel, the process of screening first and then crushing is adopted to fully improve the system's processing capacity.

Process advantage description:

1. Because the raw materials are special, the materials are pre-screened before crushing to improve the processing capacity;

2. The modular design and installation method is adopted, which is convenient and fast;

3. Design, manufacturing, construction, installation and commissioning are integrated.

Processing materials: granite gravel.

System scale: finished products below 31.5mm 200t/h.

Previous: SMP Crusher

Next: SMP Crusher

The unit modular structural parts installation method is adopted.Tibet's 200 tons per hour construction sand and gravel aggregate production line (sand and gravel crushing and processing system) is located in the Tibetan plateau.

The unit modular structural parts installation method is adopted.

Tibet's 200 tons per hour construction sand and gravel aggregate production line (sand and gravel crushing and processing system) is located in the Tibetan plateau. The system mainly produces construction sand and gravel aggregates. The system is implemented by our company for process design, equipment manufacturing, foundation construction, system installation and commissioning, training, and delivery and operation. In order to improve the system installation efficiency and save investment costs, the system's related equipment adopts the unit modular structural parts installation method. Since the source of the project is natural gravel, the process of screening first and then crushing is adopted to fully improve the system's processing capacity.

Process advantage description:

1. Because the raw materials are special, the materials are pre-screened before crushing to improve the processing capacity;

2. The modular design and installation method is adopted, which is convenient and fast;

3. Design, manufacturing, construction, installation and commissioning are integrated.

Processing materials: granite gravel.

System scale: finished products below 31.5mm 200t/h.

Previous: SMP Crusher

Next: SMP Crusher

Tangshan 800 tons per hour construction sand and gravel aggregate production line

Tangshan 800 tons per hour construction sand and gravel aggregate production line Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line

Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line Indonesia 450 tons per hour construction aggregate production line

Indonesia 450 tons per hour construction aggregate production line 1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi

1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi 1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France

1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France Tangshan 800 tons per hour construction sand and gravel aggregate production line

Tangshan 800 tons per hour construction sand and gravel aggregate production line Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line

Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line Indonesia 450 tons per hour construction aggregate production line

Indonesia 450 tons per hour construction aggregate production line 1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi

1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi 1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France

1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France