The unit modular structural component installation method is adoptedThe Indonesia 450 tons per hour construction aggregate production line project is located in Indonesia. It is a system that mainly produces sand and gravel aggregate

The unit modular structural component installation method is adopted

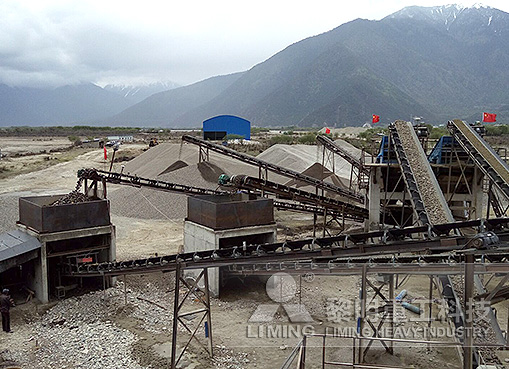

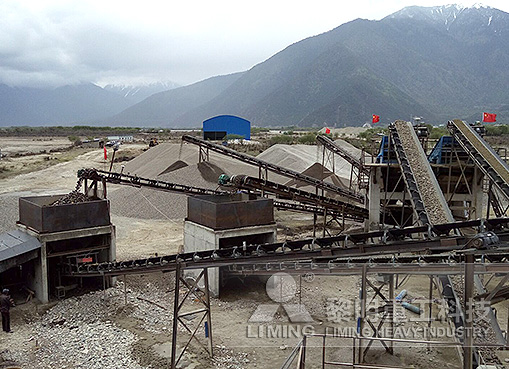

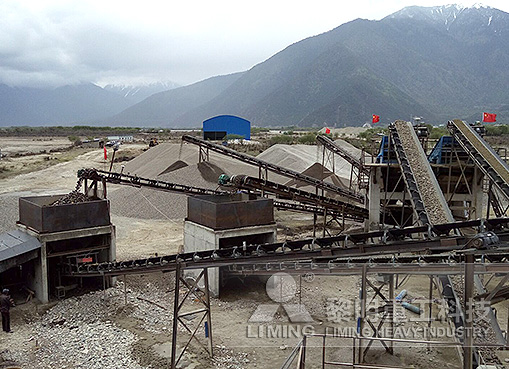

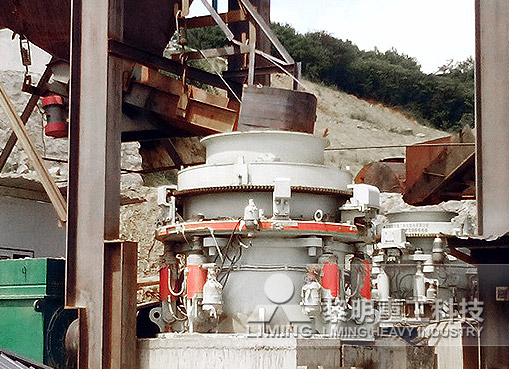

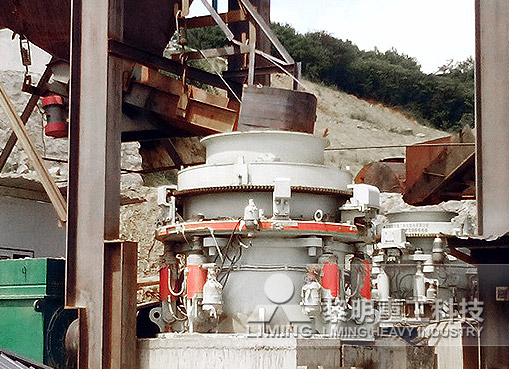

The Indonesia 450 tons per hour construction aggregate production line project is located in Indonesia. It is a system that mainly produces sand and gravel aggregates for construction. The project is jointly implemented by our company and Singapore T Company for process design, equipment manufacturing, system installation and commissioning, system training and delivery. In order to improve the system installation efficiency and save investment costs, the system adopts the unit modular structural component installation method.

Process advantage description:

1. Cooperate with international companies to design, refer to international standards, and make adaptability improvements to the local environment;

2. In order to save costs, the currently popular modular design and manufacturing method is adopted, which is convenient and fast, and easy to transport.

Processing materials: granite

Production capacity: 450t/h for finished products below 25mm.

Contractor: Luoyang Dahua / Singapore T Company

Previous: SMP Crusher

Next: SMP Crusher

The unit modular structural component installation method is adoptedThe Indonesia 450 tons per hour construction aggregate production line project is located in Indonesia. It is a system that mainly produces sand and gravel aggregate

The unit modular structural component installation method is adopted

The Indonesia 450 tons per hour construction aggregate production line project is located in Indonesia. It is a system that mainly produces sand and gravel aggregates for construction. The project is jointly implemented by our company and Singapore T Company for process design, equipment manufacturing, system installation and commissioning, system training and delivery. In order to improve the system installation efficiency and save investment costs, the system adopts the unit modular structural component installation method.

Process advantage description:

1. Cooperate with international companies to design, refer to international standards, and make adaptability improvements to the local environment;

2. In order to save costs, the currently popular modular design and manufacturing method is adopted, which is convenient and fast, and easy to transport.

Processing materials: granite

Production capacity: 450t/h for finished products below 25mm.

Contractor: Luoyang Dahua / Singapore T Company

Previous: SMP Crusher

Next: SMP Crusher

1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi

1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi 1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France

1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France High-quality sand and gravel aggregate production line for Fiji national highway construction

High-quality sand and gravel aggregate production line for Fiji national highway construction Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station

Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station 300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos

300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos 1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi

1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi 1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France

1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France High-quality sand and gravel aggregate production line for Fiji national highway construction

High-quality sand and gravel aggregate production line for Fiji national highway construction Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station

Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station 300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos

300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos