It adopts PLC automatic monitoring and controlThe 200 tons per hour dam sand and gravel aggregate processing production line project of Cameroon LOM PANGAR Hydropower Station is located in Cameroon LOM PANGAR Hydropower Station Proje

It adopts PLC automatic monitoring and control

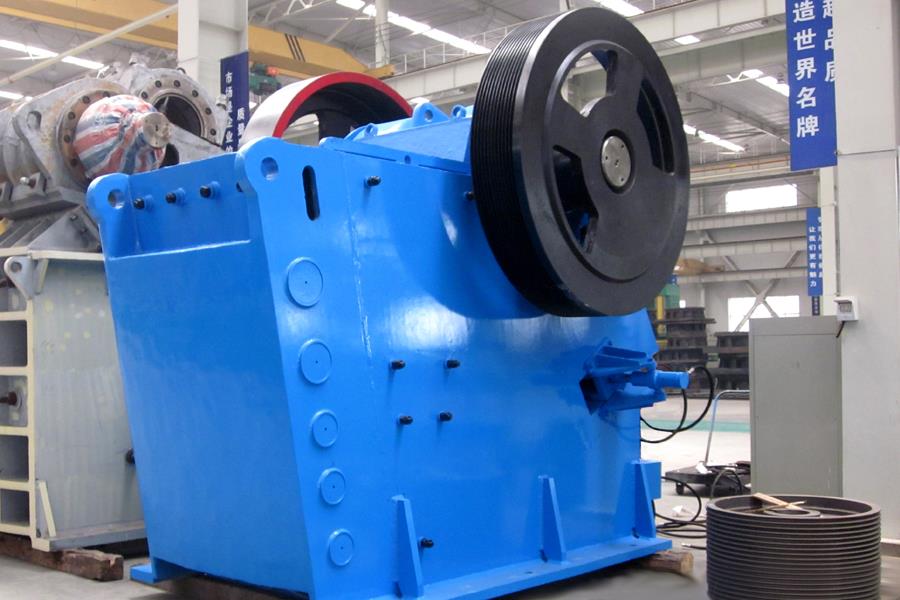

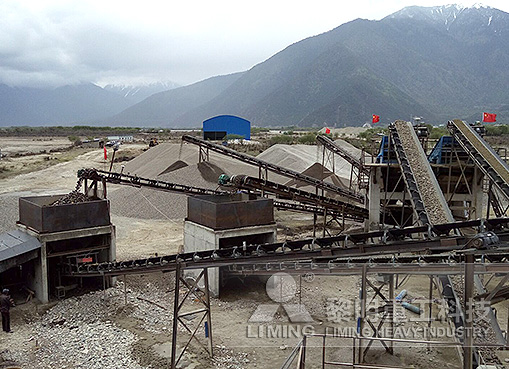

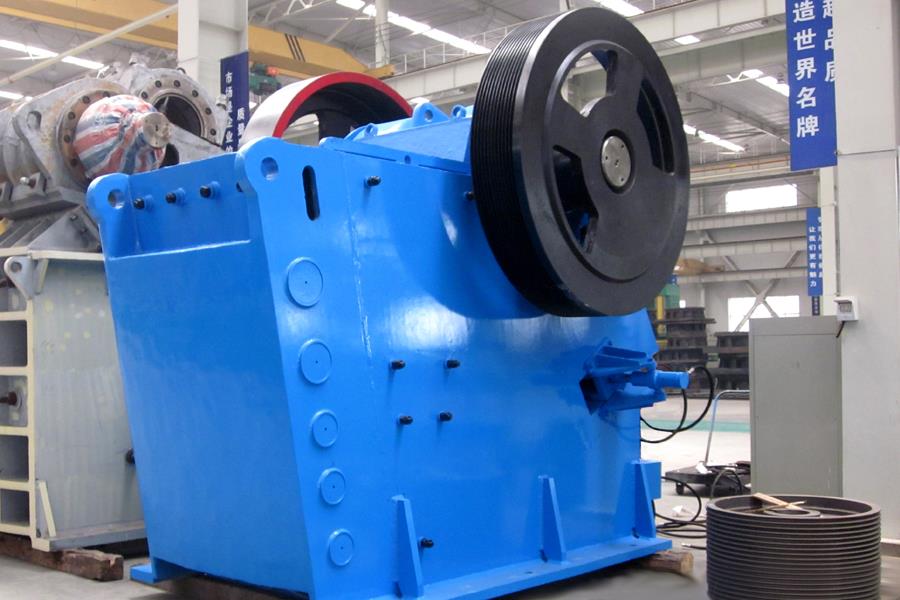

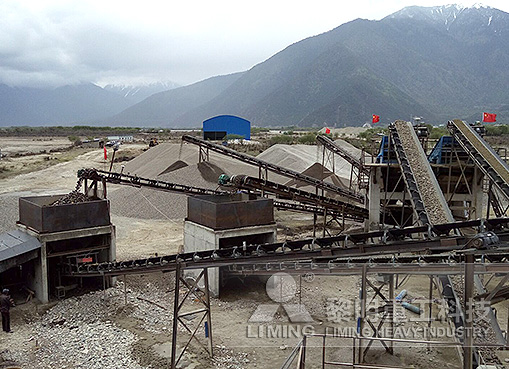

The 200 tons per hour dam sand and gravel aggregate processing production line project of Cameroon LOM PANGAR Hydropower Station is located in Cameroon LOM PANGAR Hydropower Station Project in Africa. The system mainly produces dam materials and takes into account the production of a small amount of concrete aggregates; the project uses the material excavated from the material field as the material source. The system production process and all equipment, modular structural parts, belt conveyors, and control systems are designed, manufactured, installed and debugged by our company. The system adopts some modular steel structural parts, which are easy and fast to install, with a short installation period and high efficiency, saving floor space. The electrical control system of the system adopts PLC automatic monitoring and control to ensure the safe and efficient operation of the system.

Process advantages:

1. Dam aggregates and concrete aggregates are taken into account to reduce investment costs;

2. This set of production lines is fully integrated from design, manufacturing, installation and commissioning;

3. It adopts automatic monitoring and control system, which is safe and efficient, and is equipped with environmental protection equipment, green and clean.

Previous: SMP Crusher

Next: SMP Crusher

It adopts PLC automatic monitoring and controlThe 200 tons per hour dam sand and gravel aggregate processing production line project of Cameroon LOM PANGAR Hydropower Station is located in Cameroon LOM PANGAR Hydropower Station Proje

It adopts PLC automatic monitoring and control

The 200 tons per hour dam sand and gravel aggregate processing production line project of Cameroon LOM PANGAR Hydropower Station is located in Cameroon LOM PANGAR Hydropower Station Project in Africa. The system mainly produces dam materials and takes into account the production of a small amount of concrete aggregates; the project uses the material excavated from the material field as the material source. The system production process and all equipment, modular structural parts, belt conveyors, and control systems are designed, manufactured, installed and debugged by our company. The system adopts some modular steel structural parts, which are easy and fast to install, with a short installation period and high efficiency, saving floor space. The electrical control system of the system adopts PLC automatic monitoring and control to ensure the safe and efficient operation of the system.

Process advantages:

1. Dam aggregates and concrete aggregates are taken into account to reduce investment costs;

2. This set of production lines is fully integrated from design, manufacturing, installation and commissioning;

3. It adopts automatic monitoring and control system, which is safe and efficient, and is equipped with environmental protection equipment, green and clean.

Previous: SMP Crusher

Next: SMP Crusher

Tibet 200 tons per hour construction sand and gravel aggregate production line

Tibet 200 tons per hour construction sand and gravel aggregate production line Tangshan 800 tons per hour construction sand and gravel aggregate production line

Tangshan 800 tons per hour construction sand and gravel aggregate production line Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line

Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line Indonesia 450 tons per hour construction aggregate production line

Indonesia 450 tons per hour construction aggregate production line 1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi

1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi Tibet 200 tons per hour construction sand and gravel aggregate production line

Tibet 200 tons per hour construction sand and gravel aggregate production line Tangshan 800 tons per hour construction sand and gravel aggregate production line

Tangshan 800 tons per hour construction sand and gravel aggregate production line Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line

Chongqing Haokou Hydropower Station Sand and Gravel Aggregate Processing Production Line Indonesia 450 tons per hour construction aggregate production line

Indonesia 450 tons per hour construction aggregate production line 1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi

1200 tons per hour screening, crushing and washing production line in Xianyang, Shaanxi