Asphalt concrete waste can be processed into high-quality sand and gravel aggregates by professional crushing equipment. Commonly used crushing equipment includes jaw crushers, hammer crushers, cone crushers and mobile crushers, each with its own

Asphalt concrete waste can be processed into high-quality sand and gravel aggregates by professional crushing equipment. Commonly used crushing equipment includes jaw crushers, hammer crushers, cone crushers and mobile crushers, each with its own characteristics. The purchase needs to be decided according to the needs, Shibang Group provides leading equipment.

Asphalt concrete waste mainly comes from the demolition and reconstruction of urban roads and highways. These wastes not only occupy land but may also cause environmental pollution when not processed properly. However, after being processed by professional crushing equipment, these waste materials can be transformed into high-quality sand and gravel aggregates for use in construction and transportation construction, significantly improving resource utilization. So, how to choose the right crushing equipment to process asphalt concrete waste? The following will introduce several commonly used crushing equipment and their characteristics to help you make a choice.

Asphalt concrete waste crushing equipment information

1. Jaw crusher: a powerful tool for coarse crushing

Jaw crusher is one of the earliest crushing equipments and is widely used because of its large crushing ratio and high working efficiency. The equipment has simple design, small size, reasonable structural layout, and stable and reliable operation. Its deep cavity crushing cavity can crush asphalt concrete waste into shapes through extrusion and grinding, making it suitable for primary crushing tasks. The jaw crusher is not only suitable for the coarse crushing stage, but its efficient working performance can also lay a solid foundation for the subsequent crushing process.

2. Hammer crusher: the first choice for medium crushing and environmental protection

The hammer crusher is an environmentally friendly crushing equipment that is favored for its strong sealing and low dust pollution. The hammer head of this equipment is made of wear-resistant steel, which has low wear and strong wear and pressure resistance. The hammer crusher crushes asphalt concrete waste through the impact of the hammer head, which can achieve uniform and full particle shape of the material while keeping the crushing site clean and tidy, reducing environmental pollution.

3. Cone crusher: an efficient choice for fine crushing

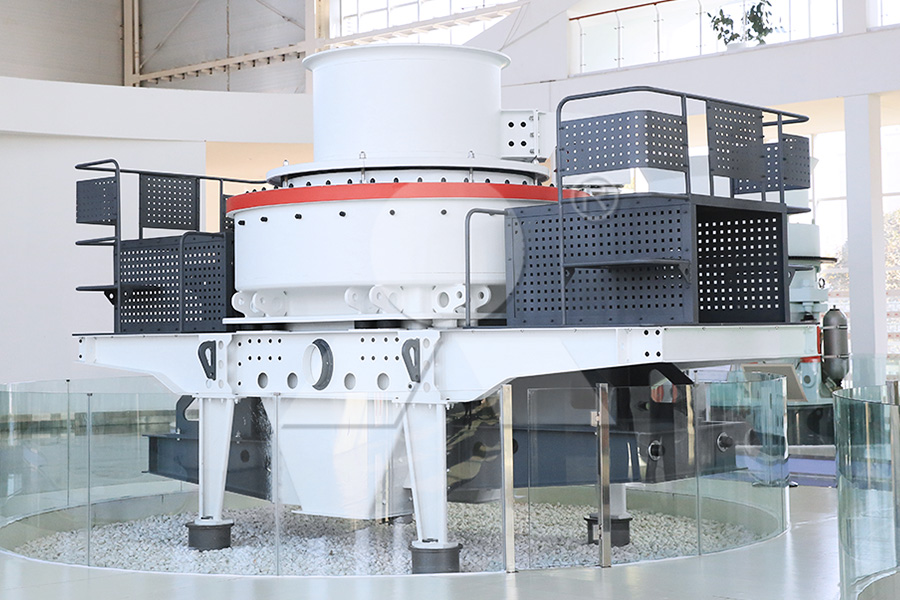

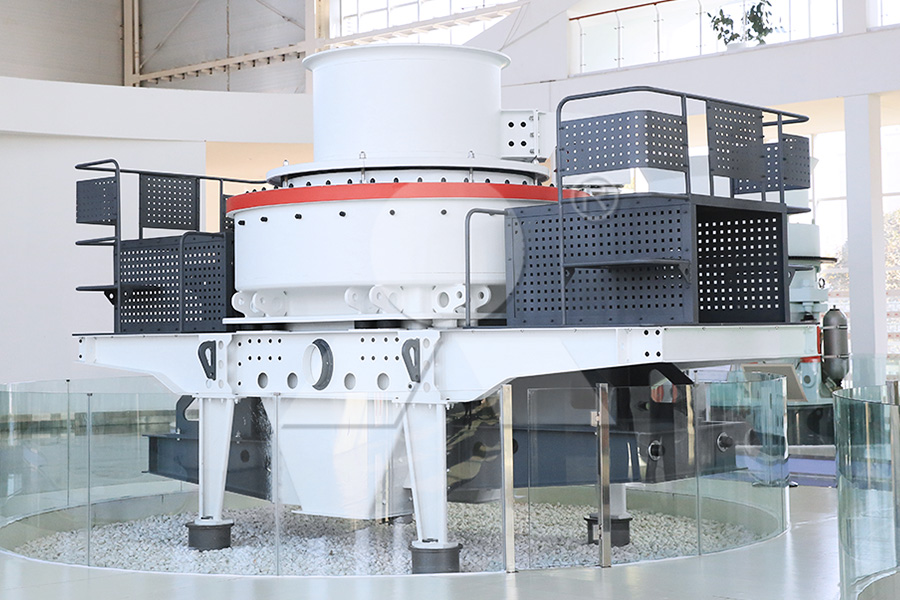

Cone crushers, especially single-cylinder cone crushers, have a high level of automation. Equipped with a PLC touch screen device system, the operator can perform remote operations, freeing his hands and effectively preventing dust from harming the operator. This equipment adopts the principle of laminated crushing, which can achieve high-quality fine crushing and produce materials with uniform particle shape and full particles, which is suitable for fine processing of asphalt concrete waste.

Mobile asphalt crushers: flexible and efficient solutions

For different operating needs, the mobile asphalt crusher provides a flexible and efficient solution. This equipment integrates feeder, crusher, vibrating screen, conveyor belt and other functions into one. The vehicle-mounted design makes it easy to reach the crushing site without foundation hardening, which greatly reduces infrastructure and installation costs. The traveling modes of mobile crushers are divided into tire type and crawler type. Main equipment of different configurations can be selected according to needs, such as jaw crusher, impact crusher, cone crusher, sand making machine, hammer crusher, etc., with an hourly output of up to 40-650 tons, meeting the crushing needs of different scales.

Equipment purchasing suggestions

Whether it is a jaw crusher, a medium hammer crusher or a tertiary cone crusher, the choice of suitable equipment needs to be determined based on specific needs and actual conditions. According to different processing stages and crushing needs, choosing the appropriate crushing equipment can not only improve production efficiency, but also effectively reduce production costs.

As an industry leader, Shibang Group is committed to providing efficient and energy-saving asphalt concrete waste crushing equipment. Understanding the complexity of asphalt concrete waste treatment, we continue to innovate in equipment design and technology to ensure that our products reach industry-leading levels in terms of performance, environmental protection and economy.

Shibang crushing equipment covers the entire process from coarse crushing to fine crushing, and can meet the needs of different customers. At the same time, mobile crusher solutions can provide convenience for projects that require flexible operations and significantly improve production efficiency.

Previous: SMP Crusher

Next: SMP Crusher

Asphalt concrete waste can be processed into high-quality sand and gravel aggregates by professional crushing equipment. Commonly used crushing equipment includes jaw crushers, hammer crushers, cone crushers and mobile crushers, each with its own

Asphalt concrete waste can be processed into high-quality sand and gravel aggregates by professional crushing equipment. Commonly used crushing equipment includes jaw crushers, hammer crushers, cone crushers and mobile crushers, each with its own characteristics. The purchase needs to be decided according to the needs, Shibang Group provides leading equipment.

Asphalt concrete waste mainly comes from the demolition and reconstruction of urban roads and highways. These wastes not only occupy land but may also cause environmental pollution when not processed properly. However, after being processed by professional crushing equipment, these waste materials can be transformed into high-quality sand and gravel aggregates for use in construction and transportation construction, significantly improving resource utilization. So, how to choose the right crushing equipment to process asphalt concrete waste? The following will introduce several commonly used crushing equipment and their characteristics to help you make a choice.

Asphalt concrete waste crushing equipment information

1. Jaw crusher: a powerful tool for coarse crushing

Jaw crusher is one of the earliest crushing equipments and is widely used because of its large crushing ratio and high working efficiency. The equipment has simple design, small size, reasonable structural layout, and stable and reliable operation. Its deep cavity crushing cavity can crush asphalt concrete waste into shapes through extrusion and grinding, making it suitable for primary crushing tasks. The jaw crusher is not only suitable for the coarse crushing stage, but its efficient working performance can also lay a solid foundation for the subsequent crushing process.

2. Hammer crusher: the first choice for medium crushing and environmental protection

The hammer crusher is an environmentally friendly crushing equipment that is favored for its strong sealing and low dust pollution. The hammer head of this equipment is made of wear-resistant steel, which has low wear and strong wear and pressure resistance. The hammer crusher crushes asphalt concrete waste through the impact of the hammer head, which can achieve uniform and full particle shape of the material while keeping the crushing site clean and tidy, reducing environmental pollution.

3. Cone crusher: an efficient choice for fine crushing

Cone crushers, especially single-cylinder cone crushers, have a high level of automation. Equipped with a PLC touch screen device system, the operator can perform remote operations, freeing his hands and effectively preventing dust from harming the operator. This equipment adopts the principle of laminated crushing, which can achieve high-quality fine crushing and produce materials with uniform particle shape and full particles, which is suitable for fine processing of asphalt concrete waste.

Mobile asphalt crushers: flexible and efficient solutions

For different operating needs, the mobile asphalt crusher provides a flexible and efficient solution. This equipment integrates feeder, crusher, vibrating screen, conveyor belt and other functions into one. The vehicle-mounted design makes it easy to reach the crushing site without foundation hardening, which greatly reduces infrastructure and installation costs. The traveling modes of mobile crushers are divided into tire type and crawler type. Main equipment of different configurations can be selected according to needs, such as jaw crusher, impact crusher, cone crusher, sand making machine, hammer crusher, etc., with an hourly output of up to 40-650 tons, meeting the crushing needs of different scales.

Equipment purchasing suggestions

Whether it is a jaw crusher, a medium hammer crusher or a tertiary cone crusher, the choice of suitable equipment needs to be determined based on specific needs and actual conditions. According to different processing stages and crushing needs, choosing the appropriate crushing equipment can not only improve production efficiency, but also effectively reduce production costs.

As an industry leader, Shibang Group is committed to providing efficient and energy-saving asphalt concrete waste crushing equipment. Understanding the complexity of asphalt concrete waste treatment, we continue to innovate in equipment design and technology to ensure that our products reach industry-leading levels in terms of performance, environmental protection and economy.

Shibang crushing equipment covers the entire process from coarse crushing to fine crushing, and can meet the needs of different customers. At the same time, mobile crusher solutions can provide convenience for projects that require flexible operations and significantly improve production efficiency.

Previous: SMP Crusher

Next: SMP Crusher

What is the production capacity of 600x900 jaw crusher? How much does it cost?

What is the production capacity of 600x900 jaw crusher? How much does it cost? What does a set of stone crushing equipment include? How much does it cost?

What does a set of stone crushing equipment include? How much does it cost? How to configure a pebble sand production line? How much does a pebble sand production line cost?

How to configure a pebble sand production line? How much does a pebble sand production line cost? What are the complete set of sand and gravel aggregate production line equipment?

What are the complete set of sand and gravel aggregate production line equipment? How to choose crushing equipment for large-scale crushing production lines in mines

How to choose crushing equipment for large-scale crushing production lines in mines What is the production capacity of 600x900 jaw crusher? How much does it cost?

What is the production capacity of 600x900 jaw crusher? How much does it cost? What does a set of stone crushing equipment include? How much does it cost?

What does a set of stone crushing equipment include? How much does it cost? How to configure a pebble sand production line? How much does a pebble sand production line cost?

How to configure a pebble sand production line? How much does a pebble sand production line cost? What are the complete set of sand and gravel aggregate production line equipment?

What are the complete set of sand and gravel aggregate production line equipment? How to choose crushing equipment for large-scale crushing production lines in mines

How to choose crushing equipment for large-scale crushing production lines in mines