There are many options for calcite crushing equipment, including jaw, impact, hammer and impact crushers. Prices vary depending on model, output and manufacturer. Shibang Group provides efficient and environmentally friendly crushing equipment to meet

There are many options for calcite crushing equipment, including jaw, impact, hammer and impact crushers. Prices vary depending on model, output and manufacturer. Shibang Group provides efficient and environmentally friendly crushing equipment to meet the needs of calcite processing.

Calcite, as an important calcium carbonate mineral, is widely used in building materials, industrial raw materials and other fields. Its rich application value has led to an increasing demand for calcite processing. So, what equipment should be chosen for crushing calcite? What is the price of a calcite crusher? This article will give you a detailed answer and attach relevant customer production line examples for reference.

Calcite Crushing Equipment Price

1. Equipment Selection for Crushing Calcite

Calcite has a Mohs hardness of 3 and is brittle in nature, so it is crucial to choose the right crushing equipment. Commonly used calcite crushing equipment includes jaw crushers, impact crushers, hammer crushers and impact crushers.

Jaw crusher

Feed size: 0-1280mm

Production capacity: 160-1510 tons/hour

Jaw crusher is generally used for coarse crushing and is suitable for processing large pieces of calcite. Its deep V-shaped crushing chamber design has no dead zone, ensuring large feed volume and efficient crushing. The wedge adjusts the discharge port, reducing the labor intensity and downtime of workers, and the finished product particle size is uniform.

Impact crusher

Feed size: 0-700mm

Production capacity: 70-400 tons/hour

Impact crusher is suitable for medium crushing and uses impact energy to crush materials. The new structural design makes it strong in rigidity, large rotor moment of inertia, good finished product particle shape, cubic, without tension and cracks, and high comprehensive benefits.

Hammer crusher

Hammer crusher is suitable for medium and fine crushing of calcite. It has a large crushing ratio, high production efficiency, uniform finished product particle size, simple equipment structure, light weight, small footprint, stable operation, safe and reliable.

Impact Crusher

Impact crusher, also known as sand making machine, is a high-yield and energy-saving fine crushing equipment. It is easy to operate, install and maintain, is less affected by the moisture content of the material, has high crushing efficiency and excellent finished product particle size.

2. Process flow of calcite crushing production line

Calcite processing into stone generally requires coarse crushing, medium and fine crushing, screening and other process flows. The specific process flow is as follows:

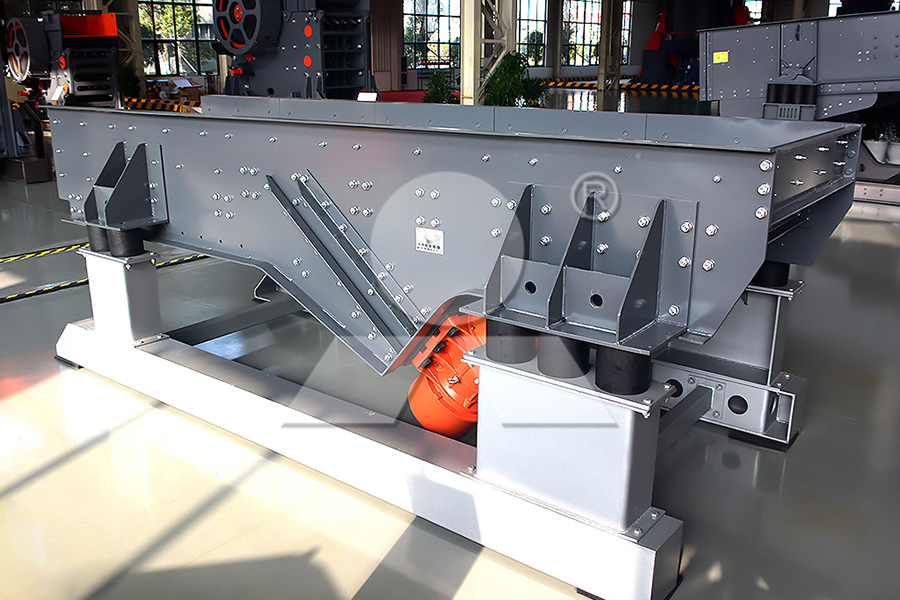

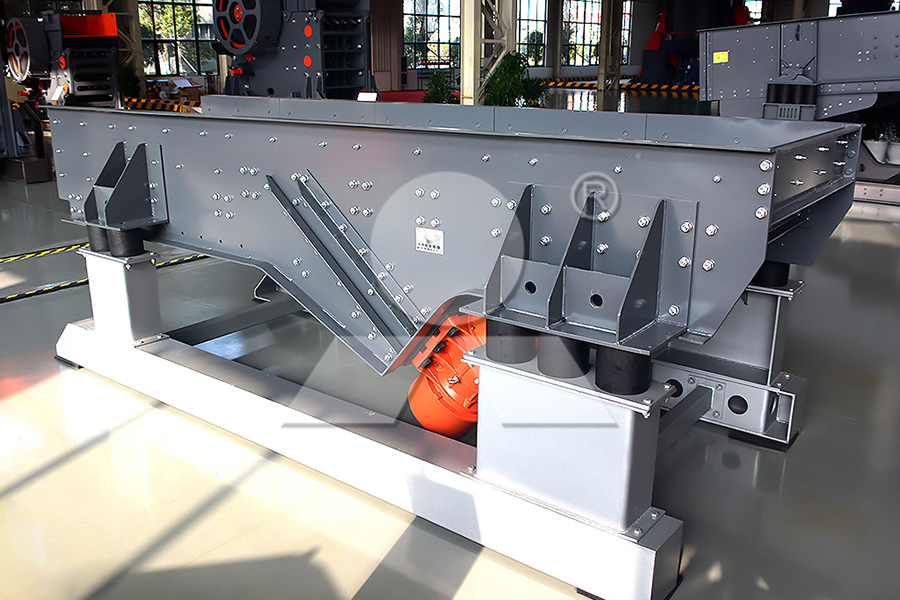

Masterbatch stacking → vibrating feeder → jaw crusher → impact crusher → vibrating screen → qualified material → belt conveyor → silo storage

Example: Guangxi customer calcite crushing production line site

Feed particle size: ≤650mm

Processing capacity: 200 tons per hour

Finished product specifications: 5-10-20-30mm

Shibang Group

Crushing/Sand Making/Grinding Consultation

Call now

3. Calcite Crusher Price

The price of calcite crusher varies depending on the equipment model, output size and manufacturer, generally ranging from tens of thousands to millions of yuan. The specific price needs to be determined according to the actual production needs and the selected equipment model.

Shibang Group believes that choosing the right crushing equipment is the key to efficient calcite processing. As an industry-leading mining equipment manufacturer, Shibang Group provides a variety of calcite crushing equipment to meet the different needs of customers. Shibang Group's equipment is efficient, environmentally friendly, and easy to operate, which can significantly improve production efficiency and reduce operating costs.

Previous: SMP Crusher

Next: SMP Crusher

There are many options for calcite crushing equipment, including jaw, impact, hammer and impact crushers. Prices vary depending on model, output and manufacturer. Shibang Group provides efficient and environmentally friendly crushing equipment to meet

There are many options for calcite crushing equipment, including jaw, impact, hammer and impact crushers. Prices vary depending on model, output and manufacturer. Shibang Group provides efficient and environmentally friendly crushing equipment to meet the needs of calcite processing.

Calcite, as an important calcium carbonate mineral, is widely used in building materials, industrial raw materials and other fields. Its rich application value has led to an increasing demand for calcite processing. So, what equipment should be chosen for crushing calcite? What is the price of a calcite crusher? This article will give you a detailed answer and attach relevant customer production line examples for reference.

Calcite Crushing Equipment Price

1. Equipment Selection for Crushing Calcite

Calcite has a Mohs hardness of 3 and is brittle in nature, so it is crucial to choose the right crushing equipment. Commonly used calcite crushing equipment includes jaw crushers, impact crushers, hammer crushers and impact crushers.

Jaw crusher

Feed size: 0-1280mm

Production capacity: 160-1510 tons/hour

Jaw crusher is generally used for coarse crushing and is suitable for processing large pieces of calcite. Its deep V-shaped crushing chamber design has no dead zone, ensuring large feed volume and efficient crushing. The wedge adjusts the discharge port, reducing the labor intensity and downtime of workers, and the finished product particle size is uniform.

Impact crusher

Feed size: 0-700mm

Production capacity: 70-400 tons/hour

Impact crusher is suitable for medium crushing and uses impact energy to crush materials. The new structural design makes it strong in rigidity, large rotor moment of inertia, good finished product particle shape, cubic, without tension and cracks, and high comprehensive benefits.

Hammer crusher

Hammer crusher is suitable for medium and fine crushing of calcite. It has a large crushing ratio, high production efficiency, uniform finished product particle size, simple equipment structure, light weight, small footprint, stable operation, safe and reliable.

Impact Crusher

Impact crusher, also known as sand making machine, is a high-yield and energy-saving fine crushing equipment. It is easy to operate, install and maintain, is less affected by the moisture content of the material, has high crushing efficiency and excellent finished product particle size.

2. Process flow of calcite crushing production line

Calcite processing into stone generally requires coarse crushing, medium and fine crushing, screening and other process flows. The specific process flow is as follows:

Masterbatch stacking → vibrating feeder → jaw crusher → impact crusher → vibrating screen → qualified material → belt conveyor → silo storage

Example: Guangxi customer calcite crushing production line site

Feed particle size: ≤650mm

Processing capacity: 200 tons per hour

Finished product specifications: 5-10-20-30mm

Shibang Group

Crushing/Sand Making/Grinding Consultation

Call now

3. Calcite Crusher Price

The price of calcite crusher varies depending on the equipment model, output size and manufacturer, generally ranging from tens of thousands to millions of yuan. The specific price needs to be determined according to the actual production needs and the selected equipment model.

Shibang Group believes that choosing the right crushing equipment is the key to efficient calcite processing. As an industry-leading mining equipment manufacturer, Shibang Group provides a variety of calcite crushing equipment to meet the different needs of customers. Shibang Group's equipment is efficient, environmentally friendly, and easy to operate, which can significantly improve production efficiency and reduce operating costs.

Previous: SMP Crusher

Next: SMP Crusher

How to choose a dolomite crusher? How much does dolomite crushing equipment cost?

How to choose a dolomite crusher? How much does dolomite crushing equipment cost? What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost?

What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost? Selection and price analysis of potassium feldspar crusher equipment

Selection and price analysis of potassium feldspar crusher equipment How to configure an efficient quartz sand production line

How to configure an efficient quartz sand production line What are the production equipment of stone factory

What are the production equipment of stone factory How to choose a dolomite crusher? How much does dolomite crushing equipment cost?

How to choose a dolomite crusher? How much does dolomite crushing equipment cost? What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost?

What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost? Selection and price analysis of potassium feldspar crusher equipment

Selection and price analysis of potassium feldspar crusher equipment How to configure an efficient quartz sand production line

How to configure an efficient quartz sand production line What are the production equipment of stone factory

What are the production equipment of stone factory