Potassium feldspar is used in many fields. Crushing equipment includes jaw, cone and impact crushers. Each equipment is suitable for different processing stages, and the price ranges from hundreds of thousands to millions. Choosing the right crushing e

Potassium feldspar is used in many fields. Crushing equipment includes jaw, cone and impact crushers. Each equipment is suitable for different processing stages, and the price ranges from hundreds of thousands to millions. Choosing the right crushing equipment can improve efficiency and finished product quality.

As an important non-metallic mineral, potassium feldspar is widely used in the ceramic industry, glass production, and compound fertilizer manufacturing. In recent years, as the importance of potassium feldspar in my country's emerging industries has gradually increased, more and more industry professionals and equipment manufacturers have begun to pay attention to potassium feldspar processing and crushing equipment. This article will introduce several commonly used potassium feldspar crusher equipment types and their discharge specifications in detail, and explore the market prices of these equipment.

Potassium feldspar crushing equipment price

1. Common potassium feldspar crushing equipment types and discharge specifications

Jaw crusher

Applicable field: Jaw crusher is widely used in the coarse crushing of various mine stones. Whether it is hard rock or soft ore, jaw crusher can handle it efficiently, especially suitable for the initial crushing of large pieces of potassium feldspar.

Working principle: The equipment crushes large pieces of material into smaller particles through the repeated movement of the moving and fixed jaw plates, providing qualified materials for the subsequent medium and fine crushing. The feed particle size can reach 1200mm, and the finished product discharge particle size is 10-350mm.

Production capacity: The production capacity is up to 1590 tons/hour.

Cone crusher

Application field: Cone crusher performs outstandingly in processing high-hardness ores, and is suitable for medium and fine crushing of hard minerals such as potassium feldspar. It adopts the principle of laminated crushing, and the crushing wall and rolling mortar wall made of high manganese steel make it have a long service life and low maintenance cost when crushing potassium feldspar.

Discharge specifications: The discharge port can be adjusted by the hydraulic motor, and the finished product particle size is 3-60mm, which can meet the needs of different users.

Production capacity: The processing capacity is 27-2181 tons/hour.

Impact crusher

Application field: When potassium feldspar needs to be processed into sand, the impact crusher is an ideal choice. This equipment can not only crush materials, but also shape the finished products through the mixed mode of "stone hitting stone" and "stone hitting iron", ensuring the excellent particle shape and reasonable gradation of sand particles.

Discharge specifications: The finished product particle size is less than 4.75mm, which can be sorted into coarse sand, medium sand and fine sand.

Production capacity: The processing capacity is 12-650 tons/hour.

2. Potassium feldspar crushing production process

The processing process of potassium feldspar mainly includes coarse crushing, medium and fine crushing, screening and transportation. Considering the hardness and density of potassium feldspar, it is recommended to use a jaw crusher for coarse crushing, and then use a cone crusher for medium and fine crushing. The specific process flow is as follows:

Coarse crushing: Large pieces of potassium feldspar are evenly fed to the jaw crusher through a vibrating feeder for preliminary crushing to obtain medium crushed materials that meet the requirements.

Medium and fine crushing: The potassium feldspar material after primary crushing enters the cone crusher for further crushing and is processed into a particle size that meets the requirements of the finished product.

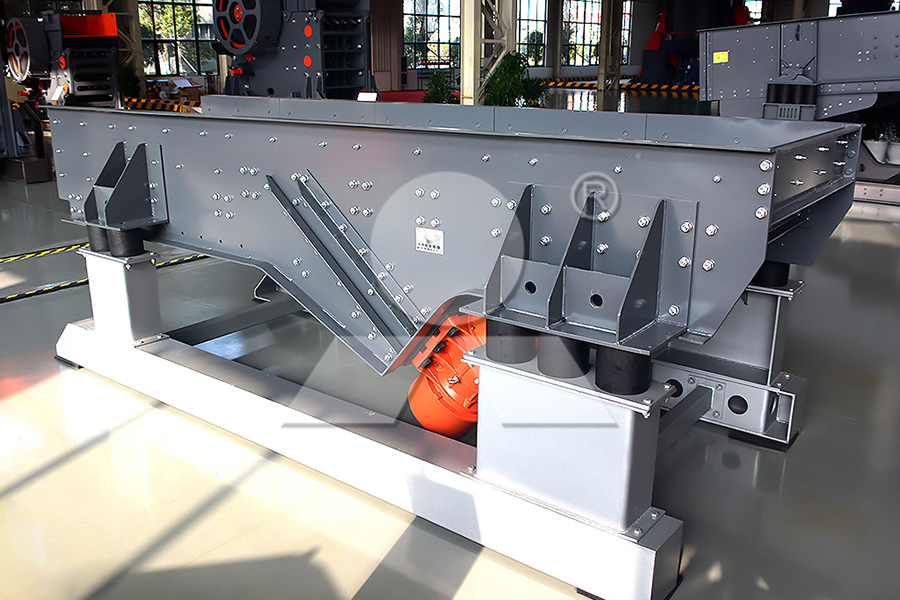

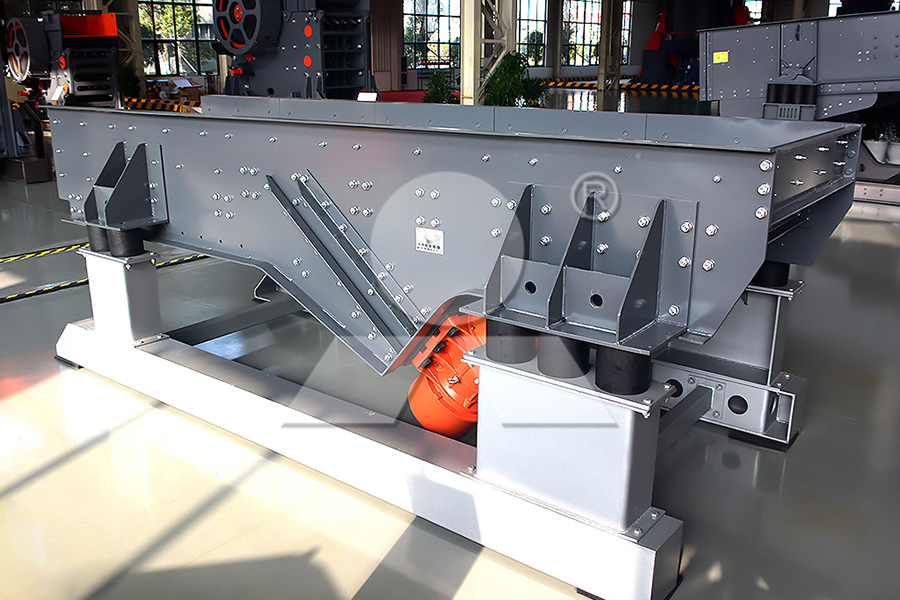

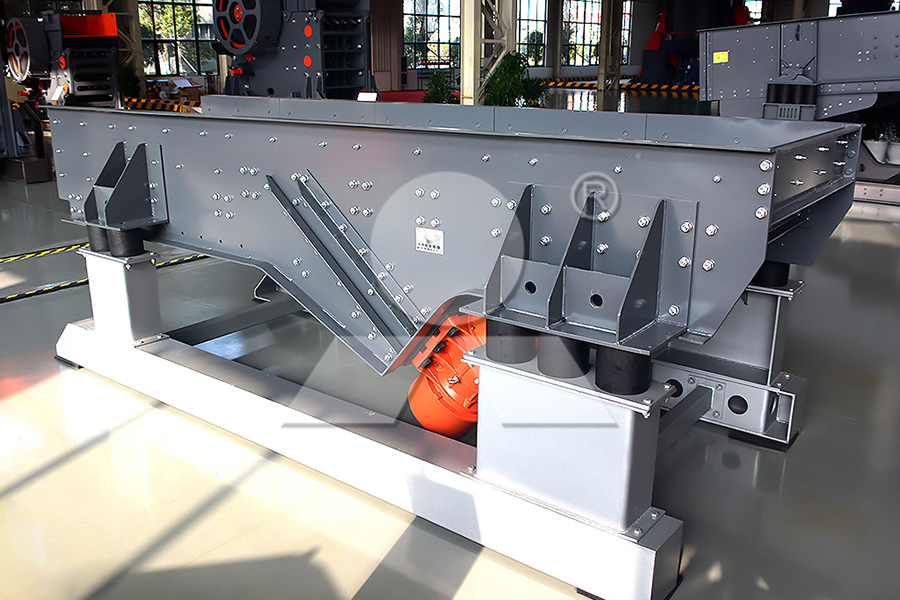

Screening: Finally, the crushed materials are screened using a vibrating screen to separate finished materials of different specifications.

III. Market price analysis of potassium feldspar crushing equipment

The price of potassium feldspar crushing equipment is affected by many factors, including equipment type, production capacity, model specifications, and the technical level of the manufacturer. Generally speaking, the prices of jaw crushers, cone crushers, and impact crushers range from hundreds of thousands to millions of yuan.

Jaw crusher: The price is relatively low, generally between hundreds of thousands and millions of yuan.

Cone crusher: Due to the high technical requirements, the price ranges from hundreds of thousands to millions of yuan, depending on the model and configuration.

Impact crusher: As a sand making equipment, the price is generally between hundreds of thousands and millions of yuan, suitable for users with different budgets.

IV. Summary

The choice of potassium feldspar crushing equipment is directly related to the efficiency of processing and production and the quality of finished products. Choosing the right crushing equipment according to actual needs can not only increase production, but also effectively reduce production costs. Whether it is the first time to purchase equipment or upgrade existing equipment, understanding the characteristics and price range of various types of potassium feldspar crushers is the key to making a wise decision.

Previous: SMP Crusher

Next: SMP Crusher

Potassium feldspar is used in many fields. Crushing equipment includes jaw, cone and impact crushers. Each equipment is suitable for different processing stages, and the price ranges from hundreds of thousands to millions. Choosing the right crushing e

Potassium feldspar is used in many fields. Crushing equipment includes jaw, cone and impact crushers. Each equipment is suitable for different processing stages, and the price ranges from hundreds of thousands to millions. Choosing the right crushing equipment can improve efficiency and finished product quality.

As an important non-metallic mineral, potassium feldspar is widely used in the ceramic industry, glass production, and compound fertilizer manufacturing. In recent years, as the importance of potassium feldspar in my country's emerging industries has gradually increased, more and more industry professionals and equipment manufacturers have begun to pay attention to potassium feldspar processing and crushing equipment. This article will introduce several commonly used potassium feldspar crusher equipment types and their discharge specifications in detail, and explore the market prices of these equipment.

Potassium feldspar crushing equipment price

1. Common potassium feldspar crushing equipment types and discharge specifications

Jaw crusher

Applicable field: Jaw crusher is widely used in the coarse crushing of various mine stones. Whether it is hard rock or soft ore, jaw crusher can handle it efficiently, especially suitable for the initial crushing of large pieces of potassium feldspar.

Working principle: The equipment crushes large pieces of material into smaller particles through the repeated movement of the moving and fixed jaw plates, providing qualified materials for the subsequent medium and fine crushing. The feed particle size can reach 1200mm, and the finished product discharge particle size is 10-350mm.

Production capacity: The production capacity is up to 1590 tons/hour.

Cone crusher

Application field: Cone crusher performs outstandingly in processing high-hardness ores, and is suitable for medium and fine crushing of hard minerals such as potassium feldspar. It adopts the principle of laminated crushing, and the crushing wall and rolling mortar wall made of high manganese steel make it have a long service life and low maintenance cost when crushing potassium feldspar.

Discharge specifications: The discharge port can be adjusted by the hydraulic motor, and the finished product particle size is 3-60mm, which can meet the needs of different users.

Production capacity: The processing capacity is 27-2181 tons/hour.

Impact crusher

Application field: When potassium feldspar needs to be processed into sand, the impact crusher is an ideal choice. This equipment can not only crush materials, but also shape the finished products through the mixed mode of "stone hitting stone" and "stone hitting iron", ensuring the excellent particle shape and reasonable gradation of sand particles.

Discharge specifications: The finished product particle size is less than 4.75mm, which can be sorted into coarse sand, medium sand and fine sand.

Production capacity: The processing capacity is 12-650 tons/hour.

2. Potassium feldspar crushing production process

The processing process of potassium feldspar mainly includes coarse crushing, medium and fine crushing, screening and transportation. Considering the hardness and density of potassium feldspar, it is recommended to use a jaw crusher for coarse crushing, and then use a cone crusher for medium and fine crushing. The specific process flow is as follows:

Coarse crushing: Large pieces of potassium feldspar are evenly fed to the jaw crusher through a vibrating feeder for preliminary crushing to obtain medium crushed materials that meet the requirements.

Medium and fine crushing: The potassium feldspar material after primary crushing enters the cone crusher for further crushing and is processed into a particle size that meets the requirements of the finished product.

Screening: Finally, the crushed materials are screened using a vibrating screen to separate finished materials of different specifications.

III. Market price analysis of potassium feldspar crushing equipment

The price of potassium feldspar crushing equipment is affected by many factors, including equipment type, production capacity, model specifications, and the technical level of the manufacturer. Generally speaking, the prices of jaw crushers, cone crushers, and impact crushers range from hundreds of thousands to millions of yuan.

Jaw crusher: The price is relatively low, generally between hundreds of thousands and millions of yuan.

Cone crusher: Due to the high technical requirements, the price ranges from hundreds of thousands to millions of yuan, depending on the model and configuration.

Impact crusher: As a sand making equipment, the price is generally between hundreds of thousands and millions of yuan, suitable for users with different budgets.

IV. Summary

The choice of potassium feldspar crushing equipment is directly related to the efficiency of processing and production and the quality of finished products. Choosing the right crushing equipment according to actual needs can not only increase production, but also effectively reduce production costs. Whether it is the first time to purchase equipment or upgrade existing equipment, understanding the characteristics and price range of various types of potassium feldspar crushers is the key to making a wise decision.

Previous: SMP Crusher

Next: SMP Crusher

How to configure an efficient quartz sand production line

How to configure an efficient quartz sand production line What are the production equipment of stone factory

What are the production equipment of stone factory Asphalt concrete waste crushing production line

Asphalt concrete waste crushing production line What is the production capacity of 600x900 jaw crusher? How much does it cost?

What is the production capacity of 600x900 jaw crusher? How much does it cost? What does a set of stone crushing equipment include? How much does it cost?

What does a set of stone crushing equipment include? How much does it cost? How to configure an efficient quartz sand production line

How to configure an efficient quartz sand production line What are the production equipment of stone factory

What are the production equipment of stone factory Asphalt concrete waste crushing production line

Asphalt concrete waste crushing production line What is the production capacity of 600x900 jaw crusher? How much does it cost?

What is the production capacity of 600x900 jaw crusher? How much does it cost? What does a set of stone crushing equipment include? How much does it cost?

What does a set of stone crushing equipment include? How much does it cost?