Dolomite crushing equipment includes jaw, impact and hammer crushers, which are widely used in building materials, chemical industry, environmental protection, etc. Prices vary depending on equipment type, specifications, production capacity and manufa

Dolomite crushing equipment includes jaw, impact and hammer crushers, which are widely used in building materials, chemical industry, environmental protection, etc. Prices vary depending on equipment type, specifications, production capacity and manufacturer. The production line is fully automated to improve efficiency and economic benefits.

As a common carbonate mineral, dolomite has a wide range of applications in building materials, ceramics, glass, refractory materials, chemical industry, agriculture, environmental protection and other fields due to its dense crystal structure, strong water resistance and high refractoriness. However, to use dolomite in these fields, it must first be crushed. So, what crushing equipment is good for dolomite? How much does a dolomite crusher cost?

Dolomite crushing equipment quotation

1. Application fields after dolomite crushing

After crushing, dolomite can be widely used in the following fields:

Building materials industry: used to produce building materials such as lime, glass, and ceramics.

Chemical industry: Dolomite can be used to produce chemical products such as fertilizers and refractory materials.

Environmental protection and agriculture: Dolomite powder can be used as a soil conditioner or neutralizer to improve soil quality and improve acidic soil.

2. Which crusher is good for dolomite?

According to the physical properties of dolomite, it is very important to choose the right crushing equipment. The hardness of dolomite is 3.5-4, it is brittle, and it is mostly in block and granular aggregates. Therefore, when choosing crushing equipment, its hardness and brittleness should be considered. The following are several commonly used dolomite crushers:

1. Jaw crusher

Jaw crusher is usually used as primary crushing equipment in dolomite crushing. It uses the extrusion between the moving jaw and the static jaw to complete the coarse crushing of dolomite. The equipment has the characteristics of large crushing ratio and uniform discharge, simple structure and convenient operation. It is an ideal choice for processing large pieces of dolomite.

2. Impact crusher

Impact crusher is suitable for secondary crushing of dolomite. It uses impact force to crush the material, and the finished product has uniform particle size and good particle shape. The equipment improves the crushing efficiency and wear resistance through optimized rotor design, and is suitable for dolomite processing with high requirements for finished product particle size.

3. Hammer crusher

Hammer crusher is a highly efficient crushing equipment suitable for medium and fine crushing of dolomite. It uses high-speed rotating hammers to impact and crush materials, and can achieve one-time forming without secondary crushing. This equipment has the characteristics of adjustable discharging particle size, simple operation and high output.

3. How much does a dolomite crusher cost?

The price of dolomite crusher varies depending on the equipment type, specification, production capacity and manufacturer. Generally speaking, the price range of dolomite crusher is wide, ranging from tens of thousands to hundreds of thousands of yuan. The main factors affecting the price include:

Equipment type: Different types of crushers have different prices. Jaw crushers are usually cheaper, while hammer crushers and impact crushers are relatively expensive.

Equipment specifications: The larger the output and model, the higher the price of the equipment. Users should choose the appropriate specifications according to actual production needs.

Manufacturer brand: Equipment from well-known brands is usually more expensive, but the quality and after-sales service are also more guaranteed.

4. Dolomite crushing production line construction plan

Depending on different production requirements and process requirements, the design plan of dolomite crushing production line will be different. The following are two common dolomite crushing production line solutions:

500 tons per hour dolomite crushing production line

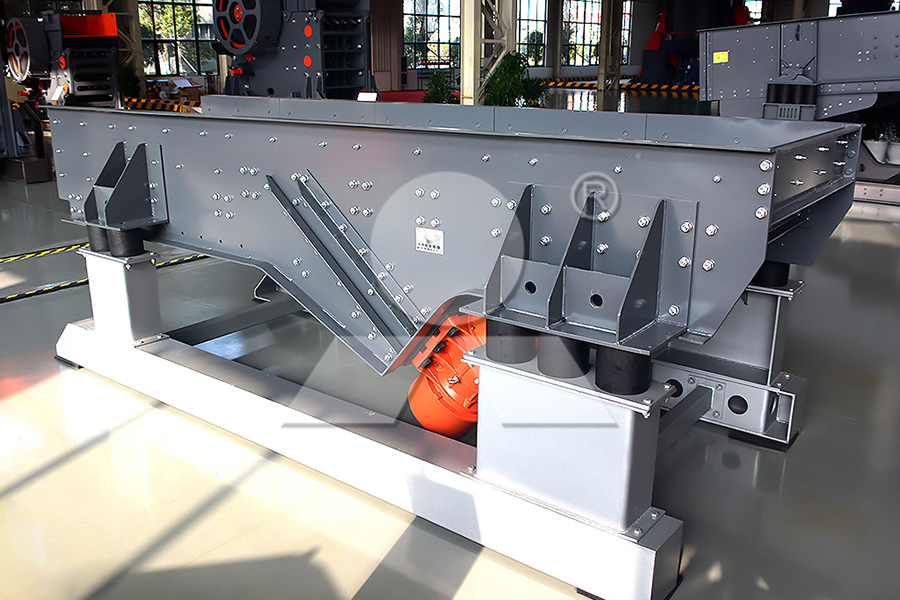

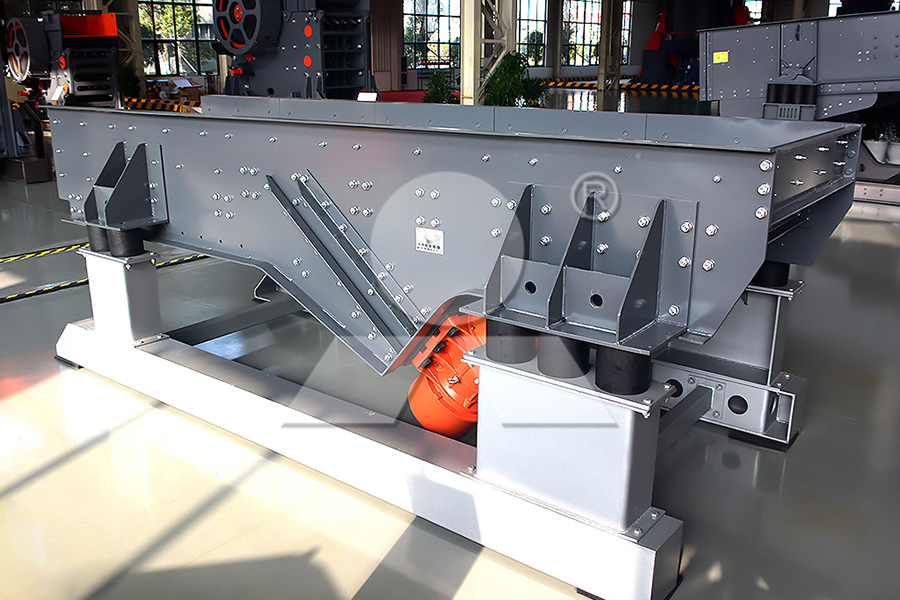

Configuration: vibrating feeder → hammer crusher → vibrating screen → conveyor

Feed particle size: ≤550mm

Finished product particle size: 0-5-10-15-30mm

200 tons per hour dolomite crushing production line

Configuration: vibrating feeder → jaw crusher → impact crusher → vibrating screen → conveyor

Feed particle size: ≤630mm

Finished product particle size: 5-10-20-30mm

Both of the above production line solutions adopt fully automated operation, which can effectively improve production efficiency and reduce labor costs, while meeting environmental protection standards and bringing higher economic benefits to customers.

The crushing and processing of dolomite is crucial in industrial applications. Choosing a suitable crusher can not only improve production efficiency, but also reduce production costs. For the price of dolomite crusher, it is recommended to consider the performance of the equipment, the reputation of the manufacturer and after-sales service when purchasing to ensure that you purchase cost-effective equipment.

Previous: SMP Crusher

Next: SMP Crusher

Dolomite crushing equipment includes jaw, impact and hammer crushers, which are widely used in building materials, chemical industry, environmental protection, etc. Prices vary depending on equipment type, specifications, production capacity and manufa

Dolomite crushing equipment includes jaw, impact and hammer crushers, which are widely used in building materials, chemical industry, environmental protection, etc. Prices vary depending on equipment type, specifications, production capacity and manufacturer. The production line is fully automated to improve efficiency and economic benefits.

As a common carbonate mineral, dolomite has a wide range of applications in building materials, ceramics, glass, refractory materials, chemical industry, agriculture, environmental protection and other fields due to its dense crystal structure, strong water resistance and high refractoriness. However, to use dolomite in these fields, it must first be crushed. So, what crushing equipment is good for dolomite? How much does a dolomite crusher cost?

Dolomite crushing equipment quotation

1. Application fields after dolomite crushing

After crushing, dolomite can be widely used in the following fields:

Building materials industry: used to produce building materials such as lime, glass, and ceramics.

Chemical industry: Dolomite can be used to produce chemical products such as fertilizers and refractory materials.

Environmental protection and agriculture: Dolomite powder can be used as a soil conditioner or neutralizer to improve soil quality and improve acidic soil.

2. Which crusher is good for dolomite?

According to the physical properties of dolomite, it is very important to choose the right crushing equipment. The hardness of dolomite is 3.5-4, it is brittle, and it is mostly in block and granular aggregates. Therefore, when choosing crushing equipment, its hardness and brittleness should be considered. The following are several commonly used dolomite crushers:

1. Jaw crusher

Jaw crusher is usually used as primary crushing equipment in dolomite crushing. It uses the extrusion between the moving jaw and the static jaw to complete the coarse crushing of dolomite. The equipment has the characteristics of large crushing ratio and uniform discharge, simple structure and convenient operation. It is an ideal choice for processing large pieces of dolomite.

2. Impact crusher

Impact crusher is suitable for secondary crushing of dolomite. It uses impact force to crush the material, and the finished product has uniform particle size and good particle shape. The equipment improves the crushing efficiency and wear resistance through optimized rotor design, and is suitable for dolomite processing with high requirements for finished product particle size.

3. Hammer crusher

Hammer crusher is a highly efficient crushing equipment suitable for medium and fine crushing of dolomite. It uses high-speed rotating hammers to impact and crush materials, and can achieve one-time forming without secondary crushing. This equipment has the characteristics of adjustable discharging particle size, simple operation and high output.

3. How much does a dolomite crusher cost?

The price of dolomite crusher varies depending on the equipment type, specification, production capacity and manufacturer. Generally speaking, the price range of dolomite crusher is wide, ranging from tens of thousands to hundreds of thousands of yuan. The main factors affecting the price include:

Equipment type: Different types of crushers have different prices. Jaw crushers are usually cheaper, while hammer crushers and impact crushers are relatively expensive.

Equipment specifications: The larger the output and model, the higher the price of the equipment. Users should choose the appropriate specifications according to actual production needs.

Manufacturer brand: Equipment from well-known brands is usually more expensive, but the quality and after-sales service are also more guaranteed.

4. Dolomite crushing production line construction plan

Depending on different production requirements and process requirements, the design plan of dolomite crushing production line will be different. The following are two common dolomite crushing production line solutions:

500 tons per hour dolomite crushing production line

Configuration: vibrating feeder → hammer crusher → vibrating screen → conveyor

Feed particle size: ≤550mm

Finished product particle size: 0-5-10-15-30mm

200 tons per hour dolomite crushing production line

Configuration: vibrating feeder → jaw crusher → impact crusher → vibrating screen → conveyor

Feed particle size: ≤630mm

Finished product particle size: 5-10-20-30mm

Both of the above production line solutions adopt fully automated operation, which can effectively improve production efficiency and reduce labor costs, while meeting environmental protection standards and bringing higher economic benefits to customers.

The crushing and processing of dolomite is crucial in industrial applications. Choosing a suitable crusher can not only improve production efficiency, but also reduce production costs. For the price of dolomite crusher, it is recommended to consider the performance of the equipment, the reputation of the manufacturer and after-sales service when purchasing to ensure that you purchase cost-effective equipment.

Previous: SMP Crusher

Next: SMP Crusher

What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost?

What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost? Selection and price analysis of potassium feldspar crusher equipment

Selection and price analysis of potassium feldspar crusher equipment How to configure an efficient quartz sand production line

How to configure an efficient quartz sand production line What are the production equipment of stone factory

What are the production equipment of stone factory Asphalt concrete waste crushing production line

Asphalt concrete waste crushing production line What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost?

What are the green and environmentally friendly sand and gravel production line equipment? How much does one set cost? Selection and price analysis of potassium feldspar crusher equipment

Selection and price analysis of potassium feldspar crusher equipment How to configure an efficient quartz sand production line

How to configure an efficient quartz sand production line What are the production equipment of stone factory

What are the production equipment of stone factory Asphalt concrete waste crushing production line

Asphalt concrete waste crushing production line