For a large-scale production line with a daily stone processing capacity of 50,000 tons, given its high capacity requirements, multiple machines are typically needed to work in tandem to ensure efficiency, as general production lines cannot achieve suc

For a large-scale production line with a daily stone processing capacity of 50,000 tons, given its high capacity requirements, multiple machines are typically needed to work in tandem to ensure efficiency, as general production lines cannot achieve such a large capacity. Based on an 8-12 hour working day, approximately 4,166 to 6,250 tons of raw material need to be processed per hour, which a single machine cannot handle. Therefore, the project plan will carefully arrange multiple crushing, screening, and conveying equipment to form a highly efficient, interconnected production line, or build multiple production lines to stably achieve the target of 50,000 tons per day, meeting the material needs of large-scale building materials production or infrastructure construction.

Click here to learn about large-scale sand and gravel production line construction solutions.

Below is a case study of a 50,000-ton-per-day stone production line:

Project Overview:

Processed Material: Granite

Feed Size: ≤1200mm

Finished Product Size: 0-5mm (3 types of finished products)

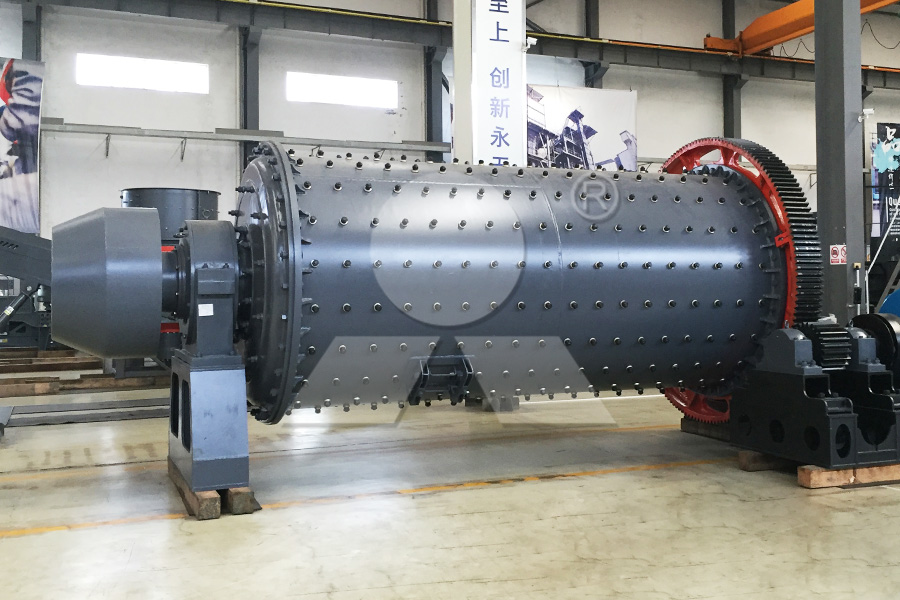

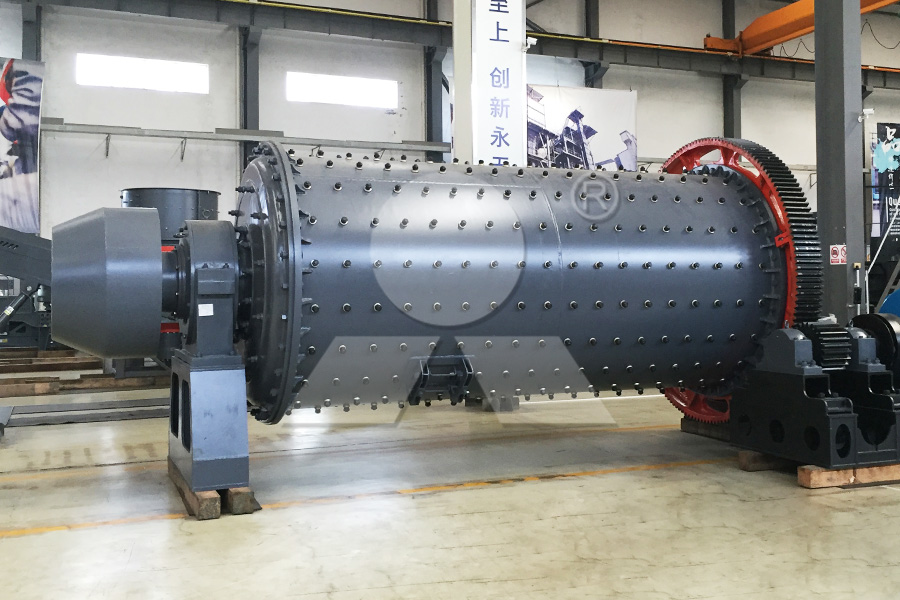

Equipment Configuration: Vibrating feeder + Jaw crusher (2 units) + Single-cylinder cone crusher (2 units) + Sand making machine (2 units) + Vibrating screen + Conveyor.

Previous: SMP Crusher

Next: SMP Crusher

For a large-scale production line with a daily stone processing capacity of 50,000 tons, given its high capacity requirements, multiple machines are typically needed to work in tandem to ensure efficiency, as general production lines cannot achieve suc

For a large-scale production line with a daily stone processing capacity of 50,000 tons, given its high capacity requirements, multiple machines are typically needed to work in tandem to ensure efficiency, as general production lines cannot achieve such a large capacity. Based on an 8-12 hour working day, approximately 4,166 to 6,250 tons of raw material need to be processed per hour, which a single machine cannot handle. Therefore, the project plan will carefully arrange multiple crushing, screening, and conveying equipment to form a highly efficient, interconnected production line, or build multiple production lines to stably achieve the target of 50,000 tons per day, meeting the material needs of large-scale building materials production or infrastructure construction.

Click here to learn about large-scale sand and gravel production line construction solutions.

Below is a case study of a 50,000-ton-per-day stone production line:

Project Overview:

Processed Material: Granite

Feed Size: ≤1200mm

Finished Product Size: 0-5mm (3 types of finished products)

Equipment Configuration: Vibrating feeder + Jaw crusher (2 units) + Single-cylinder cone crusher (2 units) + Sand making machine (2 units) + Vibrating screen + Conveyor.

Previous: SMP Crusher

Next: SMP Crusher

How to configure a mining stone production line

How to configure a mining stone production line What equipment is included in a sand making production line? How much does a set cost?

What equipment is included in a sand making production line? How much does a set cost? How was a large-scale, green, and environmentally friendly sand and gravel production line with an annual output of 5 million tons built in Wugang?

How was a large-scale, green, and environmentally friendly sand and gravel production line with an annual output of 5 million tons built in Wugang? Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing

Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing Is the Shibang HST750 cone crusher any good?

Is the Shibang HST750 cone crusher any good? How to configure a mining stone production line

How to configure a mining stone production line What equipment is included in a sand making production line? How much does a set cost?

What equipment is included in a sand making production line? How much does a set cost? How was a large-scale, green, and environmentally friendly sand and gravel production line with an annual output of 5 million tons built in Wugang?

How was a large-scale, green, and environmentally friendly sand and gravel production line with an annual output of 5 million tons built in Wugang? Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing

Case Study of 1000tph Limestone Crushing and Sand Making Production in Chongqing Is the Shibang HST750 cone crusher any good?

Is the Shibang HST750 cone crusher any good?