With the rapid development of the internet, technology and electronic devices are iterating and updating at an unprecedented pace. Meanwhile, against the backdrop of a global push for low-carbon and environmentally friendly practices, the new energy in

With the rapid development of the internet, technology and electronic devices are iterating and updating at an unprecedented pace. Meanwhile, against the backdrop of a global push for low-carbon and environmentally friendly practices, the new energy industry has ushered in unprecedented development opportunities. In this convergence of technology and environmental protection, lithium metal, as a key material, is undeniably important. Lithium ore, as the core raw material for lithium extraction, has become a focus of industry attention.

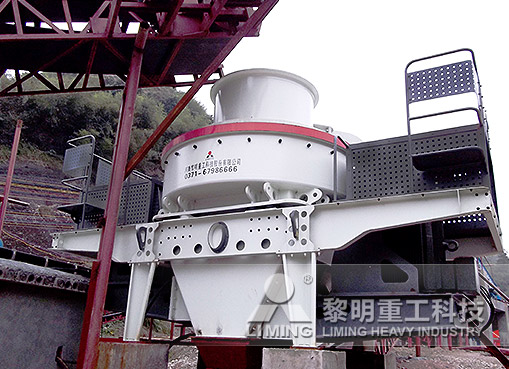

More Lithium Ore Crushing Equipment

Lithium Ore: The Cornerstone of the New Energy Industry

Lithium ore, this seemingly ordinary mineral, plays a crucial role in the new energy field. With the rapid development of my country's new energy industry, the demand for lithium ore is also increasing. To meet this huge market demand, the processes of lithium ore mining, crushing, grinding, and flotation are particularly critical.

Lithium Ore Crushing: A Dual Consideration of Efficiency and Cost

Lithium ore has a high hardness, typically between 6.5 and 8, and the raw material particle size is relatively large. To achieve efficient crushing, we usually choose a jaw crusher for initial coarse crushing, followed by a cone crusher for medium crushing to break it to a suitable particle size. This combination not only improves crushing efficiency but also reduces costs and extends equipment lifespan.

Grinding Process: Preparing for Beneficiation

After crushing, lithium ore needs to be further ground to the required fineness using a grinding mill. This process not only facilitates the individual cleavage of the lithium ore but also lays a solid foundation for subsequent beneficiation stages. Through fine grinding, we can better extract lithium resources and improve beneficiation efficiency.

Flotation Technology: Key to Lithium Ore Purification

Flotation technology is a crucial step in lithium ore purification. In the flotation process, we first roughen the crushed lithium ore using a heavy suspension to initially screen out some concentrate. Then, further flotation treatment purifies the lithium ore to a higher grade. Finally, the flotation froth and tailings products are dehydrated and separated to obtain pure lithium concentrate.

In summary, the mining, crushing, grinding, and flotation processes of lithium ore are key links in the development of the new energy industry. With continuous technological advancements and increasing market demand, we believe the lithium ore industry will usher in a broader prospect for development.

Previous: SMP Crusher

Next: SMP Crusher

With the rapid development of the internet, technology and electronic devices are iterating and updating at an unprecedented pace. Meanwhile, against the backdrop of a global push for low-carbon and environmentally friendly practices, the new energy in

With the rapid development of the internet, technology and electronic devices are iterating and updating at an unprecedented pace. Meanwhile, against the backdrop of a global push for low-carbon and environmentally friendly practices, the new energy industry has ushered in unprecedented development opportunities. In this convergence of technology and environmental protection, lithium metal, as a key material, is undeniably important. Lithium ore, as the core raw material for lithium extraction, has become a focus of industry attention.

More Lithium Ore Crushing Equipment

Lithium Ore: The Cornerstone of the New Energy Industry

Lithium ore, this seemingly ordinary mineral, plays a crucial role in the new energy field. With the rapid development of my country's new energy industry, the demand for lithium ore is also increasing. To meet this huge market demand, the processes of lithium ore mining, crushing, grinding, and flotation are particularly critical.

Lithium Ore Crushing: A Dual Consideration of Efficiency and Cost

Lithium ore has a high hardness, typically between 6.5 and 8, and the raw material particle size is relatively large. To achieve efficient crushing, we usually choose a jaw crusher for initial coarse crushing, followed by a cone crusher for medium crushing to break it to a suitable particle size. This combination not only improves crushing efficiency but also reduces costs and extends equipment lifespan.

Grinding Process: Preparing for Beneficiation

After crushing, lithium ore needs to be further ground to the required fineness using a grinding mill. This process not only facilitates the individual cleavage of the lithium ore but also lays a solid foundation for subsequent beneficiation stages. Through fine grinding, we can better extract lithium resources and improve beneficiation efficiency.

Flotation Technology: Key to Lithium Ore Purification

Flotation technology is a crucial step in lithium ore purification. In the flotation process, we first roughen the crushed lithium ore using a heavy suspension to initially screen out some concentrate. Then, further flotation treatment purifies the lithium ore to a higher grade. Finally, the flotation froth and tailings products are dehydrated and separated to obtain pure lithium concentrate.

In summary, the mining, crushing, grinding, and flotation processes of lithium ore are key links in the development of the new energy industry. With continuous technological advancements and increasing market demand, we believe the lithium ore industry will usher in a broader prospect for development.

Previous: SMP Crusher

Next: SMP Crusher

Analysis of Multi-stage Crushing Technology and Corresponding Equipment for Sand and Gravel

Analysis of Multi-stage Crushing Technology and Corresponding Equipment for Sand and Gravel A total investment of 380 million yuan! Shanghai Qingpus 500000-ton-per-year construction waste recycling production line.

A total investment of 380 million yuan! Shanghai Qingpus 500000-ton-per-year construction waste recycling production line. How should a zinc ore crushing production line with a capacity of 500 tons per hour be configured? What are the main pieces of equipment?

How should a zinc ore crushing production line with a capacity of 500 tons per hour be configured? What are the main pieces of equipment? 500-ton-per-hour basalt crushing production line: Creating an efficient and stable solution for roadbed and foundation stone production.

500-ton-per-hour basalt crushing production line: Creating an efficient and stable solution for roadbed and foundation stone production. Secrets to Improving Production Efficiency in Small Sand Making Plants: Five Practical Techniques Explained

Secrets to Improving Production Efficiency in Small Sand Making Plants: Five Practical Techniques Explained Analysis of Multi-stage Crushing Technology and Corresponding Equipment for Sand and Gravel

Analysis of Multi-stage Crushing Technology and Corresponding Equipment for Sand and Gravel A total investment of 380 million yuan! Shanghai Qingpus 500000-ton-per-year construction waste recycling production line.

A total investment of 380 million yuan! Shanghai Qingpus 500000-ton-per-year construction waste recycling production line. How should a zinc ore crushing production line with a capacity of 500 tons per hour be configured? What are the main pieces of equipment?

How should a zinc ore crushing production line with a capacity of 500 tons per hour be configured? What are the main pieces of equipment? 500-ton-per-hour basalt crushing production line: Creating an efficient and stable solution for roadbed and foundation stone production.

500-ton-per-hour basalt crushing production line: Creating an efficient and stable solution for roadbed and foundation stone production. Secrets to Improving Production Efficiency in Small Sand Making Plants: Five Practical Techniques Explained

Secrets to Improving Production Efficiency in Small Sand Making Plants: Five Practical Techniques Explained