In the sand and gravel mining industry, equipment selection is directly related to production efficiency and corporate benefits. However, many companies have fallen into the dilemma of "high input and low output" due to ignoring key details d

In the sand and gravel mining industry, equipment selection is directly related to production efficiency and corporate benefits. However, many companies have fallen into the dilemma of "high input and low output" due to ignoring key details during procurement. Only by mastering the following key points of selection can we avoid traps and choose suitable equipment.

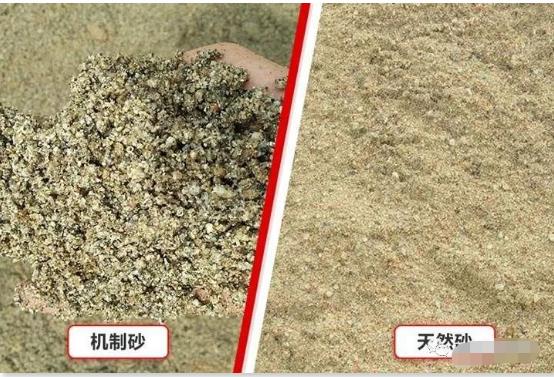

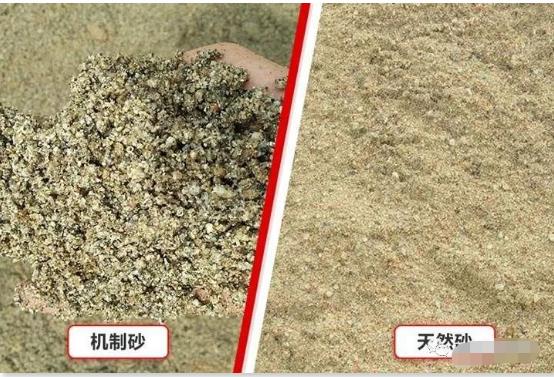

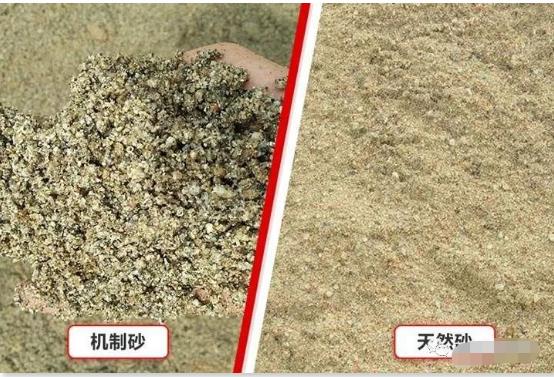

Ignoring the adaptability of material characteristics is a common misunderstanding.

Different ores have large differences in hardness and humidity. If you blindly choose equipment, it is very easy to lead to insufficient production capacity or increased equipment loss. For example, when dealing with hard materials such as granite, you need to choose equipment with strong crushing force and good wear resistance; when dealing with materials with high humidity, you need to consider anti-blocking design. Liming Heavy Industry has launched a variety of customized equipment for different material characteristics, such as cone crushers designed for hard rock crushing, which use high wear-resistant materials and optimized crushing chambers, and the crushing efficiency is increased by 30%.

It is also not advisable to pursue low prices unilaterally.

Some companies choose low-priced equipment to save costs, but ignore the quality and energy consumption of the equipment. Low-priced equipment often has a high failure rate and high energy consumption, and the subsequent maintenance and operating costs soar. When purchasing, you should pay attention to the comprehensive performance of the equipment, such as energy consumption indicators and the life of wearing parts. Although the initial investment of Liming Heavy Industry equipment is slightly higher, through innovative design, energy consumption is reduced by 20%, and the replacement cycle of wearing parts is extended by 50%, which greatly reduces costs in the long run.

Ignoring after-sales service is also a major hidden danger. The operating environment of mining equipment is complex, and failures are difficult to avoid. Timely after-sales support is crucial. Liming Heavy Industry has established a "24-hour rapid response" mechanism, and a professional team can solve equipment problems at any time to ensure uninterrupted production.

When purchasing sand and gravel mining equipment, it is necessary to comprehensively consider material adaptability, performance parameters and after-sales service. With its rich product matrix and professional services, Liming Heavy Industry provides enterprises with full-process equipment solutions to help enterprises produce efficiently, reduce costs and increase efficiency.

Previous: SMP Crusher

Next: SMP Crusher

In the sand and gravel mining industry, equipment selection is directly related to production efficiency and corporate benefits. However, many companies have fallen into the dilemma of "high input and low output" due to ignoring key details d

In the sand and gravel mining industry, equipment selection is directly related to production efficiency and corporate benefits. However, many companies have fallen into the dilemma of "high input and low output" due to ignoring key details during procurement. Only by mastering the following key points of selection can we avoid traps and choose suitable equipment.

Ignoring the adaptability of material characteristics is a common misunderstanding.

Different ores have large differences in hardness and humidity. If you blindly choose equipment, it is very easy to lead to insufficient production capacity or increased equipment loss. For example, when dealing with hard materials such as granite, you need to choose equipment with strong crushing force and good wear resistance; when dealing with materials with high humidity, you need to consider anti-blocking design. Liming Heavy Industry has launched a variety of customized equipment for different material characteristics, such as cone crushers designed for hard rock crushing, which use high wear-resistant materials and optimized crushing chambers, and the crushing efficiency is increased by 30%.

It is also not advisable to pursue low prices unilaterally.

Some companies choose low-priced equipment to save costs, but ignore the quality and energy consumption of the equipment. Low-priced equipment often has a high failure rate and high energy consumption, and the subsequent maintenance and operating costs soar. When purchasing, you should pay attention to the comprehensive performance of the equipment, such as energy consumption indicators and the life of wearing parts. Although the initial investment of Liming Heavy Industry equipment is slightly higher, through innovative design, energy consumption is reduced by 20%, and the replacement cycle of wearing parts is extended by 50%, which greatly reduces costs in the long run.

Ignoring after-sales service is also a major hidden danger. The operating environment of mining equipment is complex, and failures are difficult to avoid. Timely after-sales support is crucial. Liming Heavy Industry has established a "24-hour rapid response" mechanism, and a professional team can solve equipment problems at any time to ensure uninterrupted production.

When purchasing sand and gravel mining equipment, it is necessary to comprehensively consider material adaptability, performance parameters and after-sales service. With its rich product matrix and professional services, Liming Heavy Industry provides enterprises with full-process equipment solutions to help enterprises produce efficiently, reduce costs and increase efficiency.

Previous: SMP Crusher

Next: SMP Crusher

How to choose the right core equipment for sand and gravel mines under the wave of intelligence

How to choose the right core equipment for sand and gravel mines under the wave of intelligence What crushers are suitable for mining waste rock and tailings?

What crushers are suitable for mining waste rock and tailings? How to choose the crusher for mine waste rock and tailings

How to choose the crusher for mine waste rock and tailings Does the selection of crusher have anything to do with the size of the mine?

Does the selection of crusher have anything to do with the size of the mine? Does the brand of the crusher matter?

Does the brand of the crusher matter? How to choose the right core equipment for sand and gravel mines under the wave of intelligence

How to choose the right core equipment for sand and gravel mines under the wave of intelligence What crushers are suitable for mining waste rock and tailings?

What crushers are suitable for mining waste rock and tailings? How to choose the crusher for mine waste rock and tailings

How to choose the crusher for mine waste rock and tailings Does the selection of crusher have anything to do with the size of the mine?

Does the selection of crusher have anything to do with the size of the mine? Does the brand of the crusher matter?

Does the brand of the crusher matter?