With the continuous advancement of infrastructure construction, the demand for high-quality sand and gravel aggregates is increasing daily. Dolomite, as a common building material, has attracted much attention for its crushing and sand-making process.

With the continuous advancement of infrastructure construction, the demand for high-quality sand and gravel aggregates is increasing daily. Dolomite, as a common building material, has attracted much attention for its crushing and sand-making process. So, how much does it cost to invest in a high-efficiency dolomite crushing and sand-making machine? Below, we'll use a real-world case study to provide an in-depth understanding of the configuration and return on investment of dolomite crushing and sand-making equipment.

More Dolomite Crushing and Sand-Making Line Case Studies

Project Overview

Recently, a dolomite crushing and sand-making project with a capacity of 400-500 tons per hour officially commenced production. The dolomite used in the project comes from the client's own mine, and the finished product specifications include 0-5mm manufactured sand, 5-10mm, 10-15mm, and 15-31.5mm high-quality crushed stone, mainly used in the surrounding highway construction.

Project Equipment Configuration

The successful commissioning of this project relies heavily on the support of high-efficiency equipment. The specific configuration is as follows:

F5X Feeder: Used for stable material conveying, ensuring the efficient operation of the crusher.

C6X Jaw Crusher: Responsible for primary crushing, featuring high strength and low maintenance.

HST Single-Cylinder Hydraulic Cone Crusher: Used for medium and fine crushing, offering advantages such as high crushing efficiency and good product particle shape.

HPT Multi-Cylinder Hydraulic Cone Crusher: Further fine crushing, improving output and product quality.

VSI6X Sand Making Machine: Core sand making equipment, capable of producing high-quality manufactured sand.

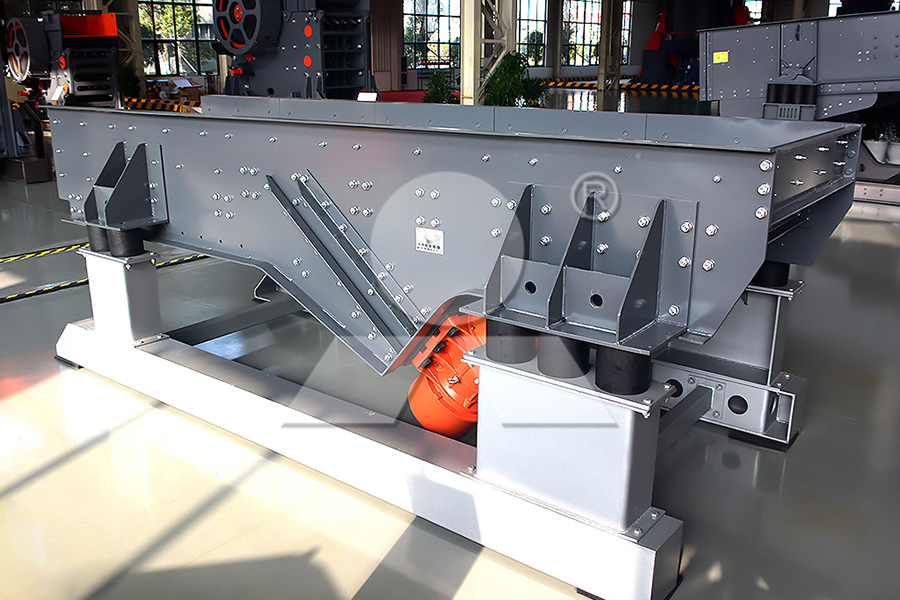

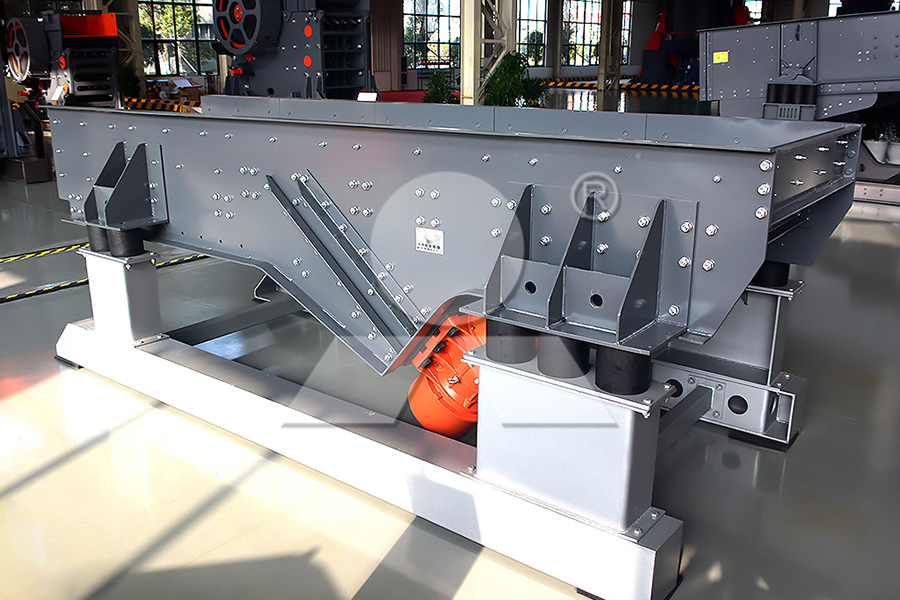

S5X Vibrating Screen: Used for screening finished products, ensuring uniform particle size to meet market demands.

Dolomite Crushing and Sand Making Machine Price: Factors affecting the price of dolomite crushing and sand making machines mainly include equipment model, configuration, production capacity, and technical services. Shibang Group's equipment is renowned for its high efficiency, durability, and intelligent management. Although the initial investment is higher, its high capacity and low operating costs can bring investors substantial returns.

Equipment Model and Configuration: Prices vary significantly depending on the model and configuration. Taking this project as an example, the entire production line is equipped with advanced F5X feeders, C6X jaw crushers, HST single-cylinder hydraulic cone crushers, HPT multi-cylinder hydraulic cone crushers, VSI6X sand making machines, and S5X vibrating screens. The total investment in these equipment ranges from several million to tens of millions of RMB.

Production Capacity: A production line with an hourly output of 400-500 tons requires efficient and stable equipment support, naturally resulting in a higher price, but it also guarantees long-term high-efficiency production.

Technical Services: Shibang Group provides comprehensive technical support and after-sales services, including equipment installation and commissioning, operation training, and regular maintenance to ensure stable equipment operation. This service is also an important component of the equipment price.

Return on Investment: Although the initial investment is large, this dolomite crushing and sand making project has already demonstrated its strong profitability. By producing high-quality manufactured sand and gravel, it meets the needs of surrounding highway construction, not only improving production efficiency but also bringing considerable economic benefits.

In conclusion, investing in a high-efficiency and environmentally friendly dolomite crushing and sand production line requires a certain amount of initial capital investment, but in the long run, its high capacity, high-quality products, and low operating costs can bring stable returns to enterprises. Shibang Group, with its leading technology and excellent service, has become the first choice for many clients. If you have similar project needs, you might consider Shibang Group's professional equipment to add strong momentum to your business.

Previous: SMP Crusher

Next: SMP Crusher

With the continuous advancement of infrastructure construction, the demand for high-quality sand and gravel aggregates is increasing daily. Dolomite, as a common building material, has attracted much attention for its crushing and sand-making process.

With the continuous advancement of infrastructure construction, the demand for high-quality sand and gravel aggregates is increasing daily. Dolomite, as a common building material, has attracted much attention for its crushing and sand-making process. So, how much does it cost to invest in a high-efficiency dolomite crushing and sand-making machine? Below, we'll use a real-world case study to provide an in-depth understanding of the configuration and return on investment of dolomite crushing and sand-making equipment.

More Dolomite Crushing and Sand-Making Line Case Studies

Project Overview

Recently, a dolomite crushing and sand-making project with a capacity of 400-500 tons per hour officially commenced production. The dolomite used in the project comes from the client's own mine, and the finished product specifications include 0-5mm manufactured sand, 5-10mm, 10-15mm, and 15-31.5mm high-quality crushed stone, mainly used in the surrounding highway construction.

Project Equipment Configuration

The successful commissioning of this project relies heavily on the support of high-efficiency equipment. The specific configuration is as follows:

F5X Feeder: Used for stable material conveying, ensuring the efficient operation of the crusher.

C6X Jaw Crusher: Responsible for primary crushing, featuring high strength and low maintenance.

HST Single-Cylinder Hydraulic Cone Crusher: Used for medium and fine crushing, offering advantages such as high crushing efficiency and good product particle shape.

HPT Multi-Cylinder Hydraulic Cone Crusher: Further fine crushing, improving output and product quality.

VSI6X Sand Making Machine: Core sand making equipment, capable of producing high-quality manufactured sand.

S5X Vibrating Screen: Used for screening finished products, ensuring uniform particle size to meet market demands.

Dolomite Crushing and Sand Making Machine Price: Factors affecting the price of dolomite crushing and sand making machines mainly include equipment model, configuration, production capacity, and technical services. Shibang Group's equipment is renowned for its high efficiency, durability, and intelligent management. Although the initial investment is higher, its high capacity and low operating costs can bring investors substantial returns.

Equipment Model and Configuration: Prices vary significantly depending on the model and configuration. Taking this project as an example, the entire production line is equipped with advanced F5X feeders, C6X jaw crushers, HST single-cylinder hydraulic cone crushers, HPT multi-cylinder hydraulic cone crushers, VSI6X sand making machines, and S5X vibrating screens. The total investment in these equipment ranges from several million to tens of millions of RMB.

Production Capacity: A production line with an hourly output of 400-500 tons requires efficient and stable equipment support, naturally resulting in a higher price, but it also guarantees long-term high-efficiency production.

Technical Services: Shibang Group provides comprehensive technical support and after-sales services, including equipment installation and commissioning, operation training, and regular maintenance to ensure stable equipment operation. This service is also an important component of the equipment price.

Return on Investment: Although the initial investment is large, this dolomite crushing and sand making project has already demonstrated its strong profitability. By producing high-quality manufactured sand and gravel, it meets the needs of surrounding highway construction, not only improving production efficiency but also bringing considerable economic benefits.

In conclusion, investing in a high-efficiency and environmentally friendly dolomite crushing and sand production line requires a certain amount of initial capital investment, but in the long run, its high capacity, high-quality products, and low operating costs can bring stable returns to enterprises. Shibang Group, with its leading technology and excellent service, has become the first choice for many clients. If you have similar project needs, you might consider Shibang Group's professional equipment to add strong momentum to your business.

Previous: SMP Crusher

Next: SMP Crusher

A limestone crushing and sand making production line with an annual output of 12 million tons.

A limestone crushing and sand making production line with an annual output of 12 million tons. How much does a mobile crushing plant cost? What factors influence the price?

How much does a mobile crushing plant cost? What factors influence the price? Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases

Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases How to Choose a Sand and Gravel Production Line Manufacturer

How to Choose a Sand and Gravel Production Line Manufacturer Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line

Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line A limestone crushing and sand making production line with an annual output of 12 million tons.

A limestone crushing and sand making production line with an annual output of 12 million tons. How much does a mobile crushing plant cost? What factors influence the price?

How much does a mobile crushing plant cost? What factors influence the price? Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases

Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases How to Choose a Sand and Gravel Production Line Manufacturer

How to Choose a Sand and Gravel Production Line Manufacturer Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line

Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line