There are several main steps to build a high-yield sand production line:Click here to consult to learn about the construction plan of the sand production line

There are several main steps to build a high-yield sand production line:

Click here to consult to learn about the construction plan of the sand production line

1. Understand the materials to be crushed and the land for production site

The first thing is the characteristics of the crushed materials, including the source of raw materials, water content and size, which directly affect the particle shape and output requirements of the finished sand. At the same time, the scale of the production site is also key, which limits the optional sand making equipment and the layout design of the overall production line. Therefore, before deciding to build a sand making machine production line, manufacturers must comprehensively evaluate the material characteristics and site conditions to ensure the efficient operation and cost-effectiveness of the production line.

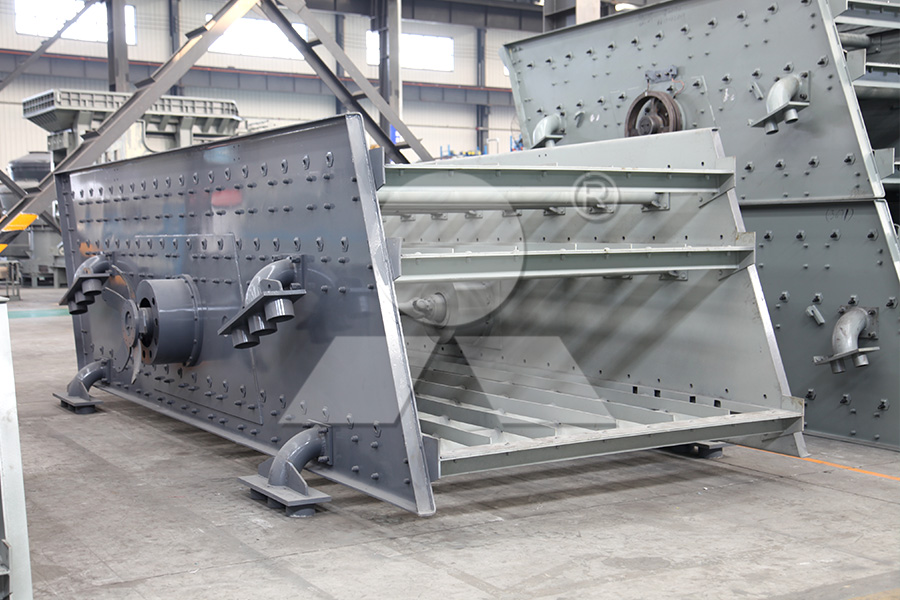

2. Reasonable selection of sand making machine equipment

After clarifying the source of raw materials, water content, size, and the particle shape and output requirements of the finished product, the selection of the main equipment of the sand making machine has a clear direction. Traditional materials such as river pebbles, granite, basalt and limestone can all be processed with suitable sand making machines. At the same time, solid wastes such as construction waste and tailings can also be processed by sand making machines and converted into machine-made sand that meets national standards. In this process, the selection of sand making machine needs to fully consider the characteristics of raw materials and product requirements to achieve efficient and environmentally friendly sand and gravel processing and production.

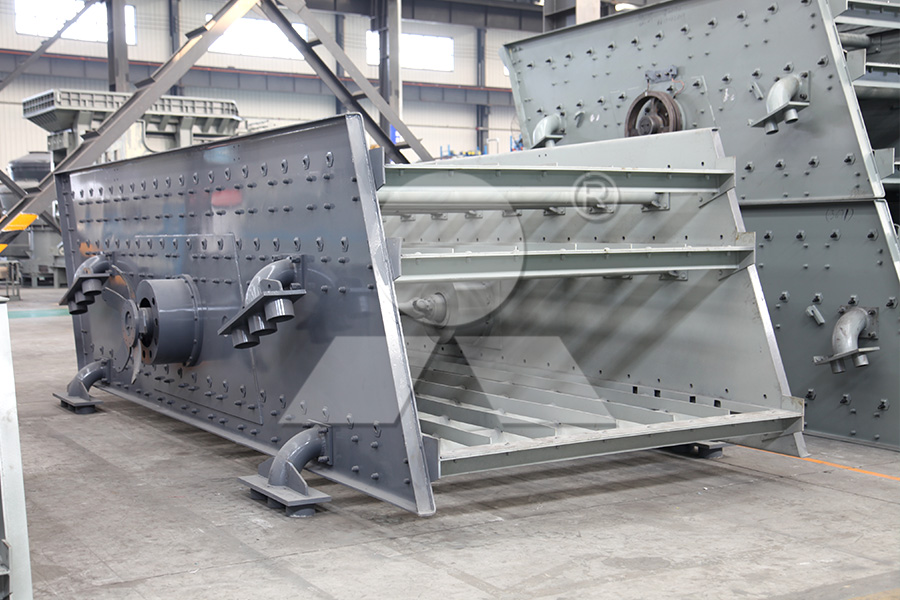

3. Overall design of the production line according to production needs

The design of the sand making machine production line is based on the layout of the production site and demand, and we need to respect the actual available space. In addition to the sand making machine, the layout of auxiliary equipment such as screening equipment and feeders also needs to be considered in a coordinated manner. In general, engineers need to conduct on-site surveys and field investigations, and then combine production needs to provide a solution that satisfies customers-a high-yield sand making machine production line.

4. Operation guarantee and after-sales maintenance of the sand making machine production line

The smooth commissioning of a production line does not mean the completion of the production line construction. On the contrary, after operation, it is an important period for how to ensure the high output and high quality of the production line. Equipment selection affects the upper limit of the output and service life of the sand making machine production line, and the operation and maintenance of the production line affects the lower limit of the output and service life of the production line. If you do not pay attention to daily maintenance, the sand making machine that could have been used for ten years may be scrapped after only two or three years due to excessive wear and other problems, which increases the operating cost in disguise.

Previous: SMP Crusher

Next: SMP Crusher

There are several main steps to build a high-yield sand production line:Click here to consult to learn about the construction plan of the sand production line

There are several main steps to build a high-yield sand production line:

Click here to consult to learn about the construction plan of the sand production line

1. Understand the materials to be crushed and the land for production site

The first thing is the characteristics of the crushed materials, including the source of raw materials, water content and size, which directly affect the particle shape and output requirements of the finished sand. At the same time, the scale of the production site is also key, which limits the optional sand making equipment and the layout design of the overall production line. Therefore, before deciding to build a sand making machine production line, manufacturers must comprehensively evaluate the material characteristics and site conditions to ensure the efficient operation and cost-effectiveness of the production line.

2. Reasonable selection of sand making machine equipment

After clarifying the source of raw materials, water content, size, and the particle shape and output requirements of the finished product, the selection of the main equipment of the sand making machine has a clear direction. Traditional materials such as river pebbles, granite, basalt and limestone can all be processed with suitable sand making machines. At the same time, solid wastes such as construction waste and tailings can also be processed by sand making machines and converted into machine-made sand that meets national standards. In this process, the selection of sand making machine needs to fully consider the characteristics of raw materials and product requirements to achieve efficient and environmentally friendly sand and gravel processing and production.

3. Overall design of the production line according to production needs

The design of the sand making machine production line is based on the layout of the production site and demand, and we need to respect the actual available space. In addition to the sand making machine, the layout of auxiliary equipment such as screening equipment and feeders also needs to be considered in a coordinated manner. In general, engineers need to conduct on-site surveys and field investigations, and then combine production needs to provide a solution that satisfies customers-a high-yield sand making machine production line.

4. Operation guarantee and after-sales maintenance of the sand making machine production line

The smooth commissioning of a production line does not mean the completion of the production line construction. On the contrary, after operation, it is an important period for how to ensure the high output and high quality of the production line. Equipment selection affects the upper limit of the output and service life of the sand making machine production line, and the operation and maintenance of the production line affects the lower limit of the output and service life of the production line. If you do not pay attention to daily maintenance, the sand making machine that could have been used for ten years may be scrapped after only two or three years due to excessive wear and other problems, which increases the operating cost in disguise.

Previous: SMP Crusher

Next: SMP Crusher

How much does a mobile crusher with an output of 100/150/300 tons per hour cost?

How much does a mobile crusher with an output of 100/150/300 tons per hour cost? Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste

Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste 500 tons per hour sand making machine price

500 tons per hour sand making machine price How to choose equipment for crushing and reusing old cement pavement

How to choose equipment for crushing and reusing old cement pavement How to configure railway ballast stone crushing and processing equipment

How to configure railway ballast stone crushing and processing equipment How much does a mobile crusher with an output of 100/150/300 tons per hour cost?

How much does a mobile crusher with an output of 100/150/300 tons per hour cost? Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste

Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste 500 tons per hour sand making machine price

500 tons per hour sand making machine price How to choose equipment for crushing and reusing old cement pavement

How to choose equipment for crushing and reusing old cement pavement How to configure railway ballast stone crushing and processing equipment

How to configure railway ballast stone crushing and processing equipment